Abstract

It is well known that thermal error has a significant impact on the accuracy of CNC machine tools. In order to decrease the thermally induced positioning error of machine tools, a novel thermal error modeling approach based on Bayesian neural network is proposed in this paper. The relationship between the temperature rise and positioning error of the feed drive system is investigated by simultaneously measuring the thermal characteristics that include the temperature field and positioning error of the CNC machine tool. Fuzzy c-means (FCM) clustering and correlation analysis are used to select temperature-sensitive points, and the Dunn index is introduced to determine the optimal number of clustering groups, which can inhibit the multicollinearity problem among temperature measuring points effectively. The least-square linear fitting is applied to explore the feature of the positioning error data. The results show that compared with the BP neural network and multiple linear regression model, the Bayesian neural network not only has higher prediction accuracy but also can guarantee excellent prediction performance under different working conditions. The prediction results obtained under different operating conditions indicate that the maximum thermal error can be reduced from around 18.2 to 5.14 μm by using the Bayesian neural network, which represents a 71% reduction in the thermally induced error of the feed drive system of machine tool.

Similar content being viewed by others

References

Li Y, Zhang X, Ran Y, Zhang W, Zhang G (2019) Reliability and modal analysis of key meta-action unit for CNC machine tool. IEEE Access 7:23640–23655

Mayr J, Jedrzejewski J, Uhlmann E, Donmez MA, Knapp W, Härtig F, Wendt K, Moriwaki T, Shore P, Schmitt R (2012) Thermal issues in machine tools. CIRP Ann 61(2):771–791

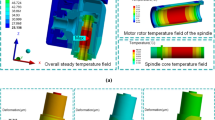

Haitao Z, Jianguo Y, Jinhua S (2007) Simulation of thermal behavior of a CNC machine tool spindle. Int J Mach Tools Manuf 47(6):1003–1010

Wu C-H, Kung Y-T (2003) Thermal analysis for the feed drive system of a CNC machine center. Int J Mach Tools Manuf 43(15):1521–1528

Horejs O (2007) Thermo-mechanical model of ball screw with non-steady heat sources. In: 2007 International Conference on Thermal Issues in Emerging Technologies: Theory and Application. IEEE, pp 133–137

Liu J, Ma C, Wang S, Wang S, Yang B, Shi H (2019) Thermal boundary condition optimization of ball screw feed drive system based on response surface analysis. Mech Syst Signal Process 121:471–495

Li B, Tian X, Zhang M (2019) Thermal error modeling of machine tool spindle based on the improved algorithm optimized BP neural network. Int J Adv Manuf Technol 105(1–4):1497–1505

Li Y, Yang J, Gelvis T, Li Y (2008) Optimization of measuring points for machine tool thermal error based on grey system theory. Int J Adv Manuf Technol 35(7–8):745–750

Wang H, Wang L, Li T, Han J (2013) Thermal sensor selection for the thermal error modeling of machine tool based on the fuzzy clustering method. Int J Adv Manuf Technol 69(1–4):121–126

Han J, Wang L, Cheng N, Wang H (2012) Thermal error modeling of machine tool based on fuzzy c-means cluster analysis and minimal-resource allocating networks. Int J Adv Manuf Technol 60(5–8):463–472

Li Y, Zhao J, Ji S, Liang F (2019) The selection of temperature-sensitivity points based on K-harmonic means clustering and thermal positioning error modeling of machine tools. Int J Adv Manuf Technol 100(9–12):2333–2348

Hao W, Hongtao Z, Qianjian G, Xiushan W, Jianguo Y (2008) Thermal error optimization modeling and real-time compensation on a CNC turning center. J Mater Process Technol 207(1–3):172–179

Huang Y, Zhang J, Li X, Tian L (2014) Thermal error modeling by integrating GA and BP algorithms for the high-speed spindle. Int J Adv Manuf Technol 71(9–12):1669–1675

Abdulshahed A, Longstaff AP, Fletcher S, Myers A (2013) Comparative study of ANN and ANFIS prediction models for thermal error compensation on CNC machine tools. In: Lamdamap 10th International Conference. euspen, pp 79–89

Abdulshahed AM, Longstaff AP, Fletcher S (2015) The application of ANFIS prediction models for thermal error compensation on CNC machine tools. Appl Soft Comput 27:158–168

Abdulshahed AM, Longstaff AP, Fletcher S, Myers A (2015) Thermal error modelling of machine tools based on ANFIS with fuzzy c-means clustering using a thermal imaging camera. Appl Math Model 39(7):1837–1852

Yang J, Shi H, Feng B, Zhao L, Ma C, Mei X (2015) Thermal error modeling and compensation for a high-speed motorized spindle. Int J Adv Manuf Technol 77(5–8):1005–1017

Ramesh R, Mannan M, Poo A, Keerthi S (2003) Thermal error measurement and modelling in machine tools. Part II. Hybrid Bayesian Network—support vector machine model. Int J Mach Tools Manuf 43(4):405–419

Snoek J, Larochelle H, Adams RP (2012) Practical Bayesian optimization of machine learning algorithms. In: Advances in neural information processing systems, pp 2951–2959

Maier M, Zwicker R, Akbari M, Rupenyan A, Wegener K (2019) Bayesian optimization for autonomous process set-up in turning. CIRP J Manuf Sci Technol 26:81–87

Burden F, Winkler D (2008) Bayesian regularization of neural networks. In: Artificial neural networks. Springer, In, pp 23–42

Ticknor JL (2013) A Bayesian regularized artificial neural network for stock market forecasting. Expert Syst Appl 40(14):5501–5506

Esme E, Karlik B (2016) Fuzzy c-means based support vector machines classifier for perfume recognition. Appl Soft Comput 46:452–458

Funding

This study was financially supported by National Key Research and Development Program of China (No. 2018YFB1703202).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shi, H., Jiang, C., Yan, Z. et al. Bayesian neural network–based thermal error modeling of feed drive system of CNC machine tool. Int J Adv Manuf Technol 108, 3031–3044 (2020). https://doi.org/10.1007/s00170-020-05541-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05541-1