Abstract

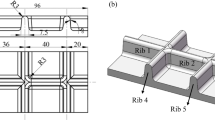

Isothermal local loading forming is a less-loading and flexible forging technology, which is promising to form the ultra-large-size integrated component with multi-rib by adopting small tonnage equipment. Due to the local loading characteristic, the material in the loading region can transfer into the unloading region in the transitional region. Identifying the affect region of the material transfer is important to control the material flow and obtain high-quality components under local loading way. In this work, the phenomena of the material transfer are explored and the boundaries of the transitional region are clarified. Firstly, the material transfer after each loading step is analyzed by displacement field and strain field based on finite element simulation of the ultra-large component. Meanwhile, the velocity vectors during each loading step are observed. Secondly, the variations of the material volume in different loading zones during each loading step are revealed. Subsequently, the change of material volume located far from the die partition line is analyzed. Furthermore, the induced forming problems by the material transfer effect, i.e., folding and additional strain, are elaborated. Finally, the boundaries between the transitional region and first/second loading zone are determined. The phenomena of the material transfer and the induced folding in the transitional region are verified using an eigenstructure with multi-rib by the FE simulation and physical simulation experiment.

Similar content being viewed by others

References

Shen GS, Furrer D (2000) Manufacturing of aerospace forgings. J Mater Process Technol 98:189–195

Fan XG, Yang H, Gao PF (2014) Through-process macro-micro finite element modeling of local loading forming of large-scale complex titanium alloy component for microstructure prediction. J Mater Process Technol 214(2):253–266

Yuan SJ, Fan XB (2019) Developments and perspectives on the precision forming processes for ultra-large size integrated components. Int J Extrem Manuf 022002(1):1–18

Chen F, Cui Z, Chen J (2014) Prediction of microstructural evolution during hot forging. Manufacturing Rev 1(6):1–21

Chen F, Ren FC, Chen J, Cui ZS, Ou HA (2016) Microstructural modeling and numerical simulation of multi-physical fields for martensitic stainless steel during hot forging process of turbine blade. Int J Adv Manuf Technol 82(1–4):85–98

Yang H, Fan XG, Sun ZC, Guo LG, Zhan M (2011) Recent developments in plastic forming technology of titanium alloys. Sci China Technol Sci 54(2):490–501

Yang H, Fan XG, Sun ZC, Guo LG, Zhan M (2011) Some advances in local loading precision forming of large scale integral complex components of titanium alloys. Mater Res Innov 15(S1):493–498

Zhang DW, Fan XG (2018) Review on intermittent local loading forming of large-size complicated component: deformation characteristics. Int J Adv Manuf Technol 99(5–8):1427–1448

Gao PF, Li XD, Yang H, Fan XG, Lei ZN (2016) Influence of die parameters on the deformation inhomogeneity of transitional region during local loading forming of Ti-alloy rib-web component. Int J Adv Manuf Technol 90(5–8):2109–2119

Gao PF, Liu ZF, Lei ZN (2017) Deformation characteristics of transitional region during local loading forming of Ti-alloy rib- web component on the double-action press. Int J Adv Manuf Technol 93(1–4):559–569

Gao PF, Yang H, Fan XG (2014) Quantitative analysis of the material flow in transitional region during isothermal local loading forming of Ti-alloy rib-web component. Int J Adv Manuf Technol 75(9):1339–1347

Sun ZC, Yang H, Sun NG (2009) Simulation on local loading partition during titanium bulkhead isothermal forming process. J Plast Eng 16(1):138–143 (in Chinese)

Sun ZC, Yang H (2009) Forming quality of titanium alloy large-scale integral components isothermal local loading. Arab J Sci Eng 34(Number 1C):35–45

Fan XG, Yang H, Sun ZC, Zhang DW (2010) Effect of deformation inhomogeneity on the microstructure and mechanical properties of large-scale rib-web component of titanium alloy under local loading forming. Mater Sci Eng A 527(21–22):5391–5399

Zhang DW, Yang H (2014) Distribution of metal flowing into unloaded area in the local loading process of titanium alloy rib-web component. Rare Metal Mater Eng 43(2):296–300

Gao PF, Yang H, Fan XG, Lei PH (2014) Forming defects control in transitional region during isothermal local loading of Ti-alloy rib-web component. Int J Adv Manuf Technol 76(5):857–868

Gao PF, Yang H, Fan XG (2015) Quick prediction of the folding defect in transitional region during isothermal local loading forming of titanium alloy large-scale rib-web component based on folding index. J Mater Process Technol 219:101–111

Wei K, Fan XG, Zhan M, Yang H, Gao PF (2017) Improving the deformation homogeneity of the transitional region in local loading forming of Ti-alloy rib-web component by optimizing unequal-thickness billet. Int J Adv Manuf Technol 92(9–12):4017–4029

Wei K, Zhan M, Fan XG, Yang H, Gao PF, Meng M (2018) Unequal-thickness billet optimization in transitional region during isothermal local loading forming of Ti-alloy rib-web component using response surface method. Chin J Aeronaut 31(4):845–859

Wei K, Fan XG, Zhan M, Zeng X, Jiang XQ (2018) Uncertainty analysis and multi-objective billet robust optimization for transitional region of multi-rib component under isothermal local loading forming. Int J Adv Manuf Technol 97(1–4):1165–1179

Chan WL, Fu MW, Lu J, Chan LC (2009) Simulation-enabled study of folding defect formation and avoidance in axisymmetrical flanged components. J Mater Process Technol 209(11):5077–5086

Sun ZC, Cao J, Wu HL, Yin ZK (2018) Inhomogeneous deformation law in forming of multi-cavity parts under complex loading path. J Mater Process Technol 254(11):179–192

Gao PF, Yan XG, Fei MY, Zhan M, Li YK (2019) Formation mechanisms and rules of typical types of folding defects during die forging. Int J Adv Manuf Technol 104(5):1603–1612

Wei K, Yang H, Fan XG, Gao PF (2015) Unequal thickness billet design for large-scale titanium alloy rib-web components under isothermal closed-die forging. Int J Adv Manuf Technol 81(5):729–744

Zhang DW, Yang H, Li HW, Fan XG (2012) Friction factor evaluation by FEM and experiment for TA15 titanium alloy in isothermal forming process. Int J Adv Manuf Technol 60(5–8):527–536

Sun ZC, Yang H, Sun NG (2012) Effects of parameters on inhomogeneous deformation and damage in isothermal local loading forming of Ti-alloy component. J Mater Eng Perform 21(3):313–323

Shen CW (2007) Research on material constitution models of TA15 and TC11 titanium alloys in hot deformation process. Master Thesis, Northwestern Polytechnical University

Dutta A, Rao AV (1997) Simulation of isothermal forging of compressor disc by combined numerical and physical modeling techniques. J Mater Process Technol 72(3):392–395

Zhang DW, Yang H, Sun ZC (2010) Analysis of local loading forming for titanium alloy T-shaped components using slab method. J Mater Process Technol 210(2):258–266

Funding

This paper was financially supported by the Natural Science Foundation of Jiangxi Province (No. 20192BAB216023), Natural Science Foundation of China (No. 51975267, No. 51965043), and PhD Starting Foundation of Nanchang Hangkong University (No. 2030009401056).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wei, K., Ma, Q., Wang, G. et al. Exploration of the material transfer effect in local loading forming of ultra-large-size integrated component with multi-rib. Int J Adv Manuf Technol 108, 1413–1427 (2020). https://doi.org/10.1007/s00170-020-05517-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05517-1