Abstract

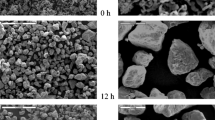

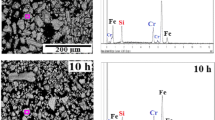

Nanocrystalline Cr50Ni50 material was obtained by high-energy ball milling from pure Cr and Ni powders in a planetary ball-mill P7 under argon atmosphere at ambient temperature. Microstructural, structural, morphological, magnetic, and densification properties were studied by X-ray diffraction, scanning electron microscopy, magnetic measurements, and cold compaction followed by sintering. The Rietveld refinement of the X-ray diffraction pattern reveals after 1 h of milling the formation of the disordered fcc-Ni (Cr) solid solution in addition to pure Cr and Ni. After 25 h of milling, the interdiffusion between Cr and Ni atoms leads to the formation of a mixture of disordered fcc-Ni(Cr) and bcc-Cr(Ni) solid solutions. The average thickness of the grain boundaries <EJ > of bcc-Cr(Ni) and fcc-Ni(Cr) is of about 3.5 and 2.3 nm, respectively. The morphological observations reveal the fragile aspect of the powder particles which is explained by their fragmentation at different stages of the milling process. The existence of small magnetic particles which are typically single domains is evidenced by Mr/Ms (0.1–0.5) values. The porosity fraction of the cold compacted powders is about 25% then decreases to about 12% after sintering at 1250 °C for 2 h. The Vickers microhardness values of the milled powders for 25 h evolute from 1045 to 1280 Hv while those of the sintered powders vary in the range 716 to 995 Hv.

Similar content being viewed by others

References

Yuji K, Hirokazu T, Masami S, Hajime N (1997) Creep rupture properties of a Ni-Cr-W superalloy in air environment. J Nucl Mater 246:196–205

Her-Hsiung H (2002) Effect of chemical composition on the corrosion behavior of Ni-Cr-Mo dental casting alloys. J Biomed Mater Res 60:458–465

Luiz BO, Hamilton P, Osvaldo Z, Cambuy d STB (2004) Effect of casting technique on surface roughness and consequent mass loss after polishing of NiCr and CoCr base metal alloys: a comparative study with titanium. J Prosthet Dent 92:7–274

Perez-Campos A, Iriarte GF, Lebedev V, Calle F (2014) Post CMOS compatible sacrificial layers for aluminum nitride microcantilevers. J Micro Nanolith 13:043012

Das S, Seol JB, Kim YC, Park CG (2010) Structure and mechanical properties of Ni–Cr alloy produced by single roll strip casting. Mater and Design 31:570–573

Survilienė S, Češūnienė A, Jasulaitienė V, Jurevičiūtė I (2012) The use of XPS for study of the surface layers of CrNi alloys electrodeposited from the Cr (III)+ Ni (II) bath. J Appl Surf Sci 258:9902–9906

Chang SH, Liao CL, Huang KT, Wu MW (2016) Investigation of the characteristics of submicron-structured powder-fabricated Cr50Ni50 alloys via different hot-press sintering pressures. Mater.Trans. 57:732–737

Triaaa S, Faghia L, Otmaneb F, Kali-alic F, Azzaza M (2014) Characteristics of nanostructured Cr75Ni25 alloy powders produced by high-energy ball milling. J Nano Res 29:13–21

Gleiter H (1990) Nanocrystalline materials. Prog Mater Sci 33:223–315

Suryanarayana C (2001) Mechanical alloying and milling. Prog Mater Sci 46:1–184

L. Dekhil, S. Alleg, J.J. Suñol, J.M. Greneche, X-ray diffraction and Mössbauer spectrometry studies of the mechanically alloyed Fe–6P–1.7C powders, Adv. Powder Technol, 20 (2009) 593–597

Dekhil L, Alleg S, Bououdina M, Suñole JJ, Grenèche JM (2015) Phase transformations and magnetic properties of ball-milled Fe-6P-1.7C powders. Adv powd, Technol 26(2015):519–526

Fellah M, Hezil N, Dekhil L, Samad MA, Djellabi R, Kosma S, Montagne A, Iost A, Obrosov A, Weiss S (2019) Effect of sintering temperature on structure and tribological properties of nanostructured Ti−15Mo alloy for biomedical applications. Trans Non Fer Metal Soc China 29:2310–2320

M. Fellah, N. Hezil, K. Abderrahim, M. A. Samad, A. Montagne, A. Mejias, A. Iost, S. Kossman, T. Chekalkin, A. Obrosov, S. Weiss, Investigating the effect of sintering temperature on structural and tribological properties of a nanostructured Ti-20Nb-13Zr alloy for biomedical applications, The minerals, metals and materials series, Chapter. (2020)

L. Dekhil, S. Louidi, M. Bououdina, M. Fellah, Microstructural, magnetic and nanoindentation studies of the ball-milled Ti80Ni20 alloy, J .Supercond. Nov Magn. 31 (2019)

Das J, handra C, Misra PS, Sarma B (2008) Mater Sci Eng:470

Lindskog P (1973) The effect of phosphorus addition on the sponge iron powder. J Appl Metall 16:374–386

MAUD program, www.ing.unitn.it/∼maud/

Rietveld HM (1969) A profile refinement method for nuclear and magnetic structures. J Appl Crystallogr 2:45–48

Schneider CA, Rasband WS, Eliceiri KW (2012) Image analysis. Nat Methods 7:671–675

panel I, Gheno T, Jomard F, Desgranges C, Martnelli L (2018) Tracer diffusion of Cr in Ni and Ni-22Cr studied by SIMS. J Mtla Elsev 3:145–152

Zerniz N, Azzaza S, Chater R, Abbasd H, Bououdina M, Bouchelaghem W (2015) Magnetic and structural properties of nanostructured Fe-20Al-2Cr powder mixtures. Mater Character 100:21–30

H. Guerault, Thesis of Doctorat, Propriétés structurales et magnétiques de poudres de Fluorures nanostructurées MF (M=Fe, Ga) obtenues par broyage mécanique, Université du Maine-France. (2000)

M. Grafoute, Thesis of Doctorat, Etude des propriétés structurales et modélisations de poudres nanostructurées de fer obtenues par broyage mécanique, Université du Maine-France. (2004)

Khaneghahi SF, Sharafi S (2014) Magnetic and structural properties of nanostructured (Fe65Co35)1001-xCrx(x = 0, 10) powders prepared by mechanical alloying process. Advanc Pow Technol 25:211–218

A. Mehmet, Constitution and magnetism of iron and its alloys, ebook. (2001)

Fenineche NE, Hamzaoui R, ElKedim O (2003) Structure and magnetic properties of nanocrystalline co–Ni and co–Fe mechanically alloyed. Mater Let 57:4165–4169

Hahn H, Logas J, Averbac RS (1990) J Mater Res 7:1489–1500

Kahloul L, Chadli H, Beliardouh NE, Bououdina M (2019) Cold pressing dependence on microstructure and electrochemical performance of porous TiNi alloy. Mater Res Exp 6(9):096559

E. Dominguez, Thesis of Doctorat, Université de Paris-France. (1996)

Kahloul L, Chadli H, Montagne A, Iost A, Hervas I, Labaiz M (2017) Effect of sintering temperature on the mechanical and tribological behavior of porous TiNi alloy. J Mater Tech 105:404

M. Sung H. Whang, Nanostructured metals and alloys, processing, microstructure, mechanical properties and applications. A volume in Woodhead Publishing Series in Metals and Surface Engineering. Book. (2011)

El-sherik AM, Erb U, Palumbo G, Aust KT (1995) Thermal stability of nanocrystalline Ni. Mater Sci Eng A 203:177–186

Acknowledgments

This research work was supported by the DGRSDT/PNR project, 2011 (MESRS) Algeria. The authors are very grateful to Jean-Marc Grenèche from Laboratoire de Physique de l’état condensé, Université du Maine, France, for technical resources and to Kahloul Latifa from Ecole Nationale Supérieure des Mines et Métallurgie, Annaba, Algérie for EDS characterization.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dekhil, L., Hanneche, N., Fellah, M. et al. Structural analysis and densification study of the mechanically alloyed Cr50Ni50 powders. Int J Adv Manuf Technol 108, 2515–2524 (2020). https://doi.org/10.1007/s00170-020-05504-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05504-6