Abstract

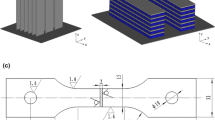

Ti6Al4V specimens were produced using electron beam melting (EBM) with the goal of studying the effects of the scanning strategies on the surface morphology, microstructure, and mechanical properties. As the factory condition consists in the use of different parameters for scanning the hatch and the contour, additional processing conditions were investigated using the hatch and contour strategies separately, oriented from the center to the border, and vice versa. Due to material anisotropy, the samples were fabricated in both the vertical and planar directions. This work demonstrates that the scanning strategies affect several features of EBMed TiAl4V samples, like the relative density of the specimens, the surface morphology, and the microstructure and mechanical properties. In details, pure contour can increase the relative density, due to the use of pulses instead of continuous electron beam emission, while the hatch scanning produces smoother and more uniform surface morphology. As different thermal histories can be associated with the variation of the scanning strategy, the microstructure can be varied in terms of grain growth. Finally, the tensile behavior of the specimens, evaluated in both the principal orientations, can be correlated to the relative density and surface irregularity.

Similar content being viewed by others

References

Beretta S, Romano S (2017) A comparison of fatigue strength sensitivity to defects for materials manufactured by AM or traditional processes. Int J Fatigue 94:178–191

Cheng B, Price S, Gong X, Lydon J, Cooper K, Chou K (2014) Speed function effects in electron beam additive manufacturing. ASME Int Mech Eng Congr Expo Proc 2A:1–9

De Formanoir C, Michotte SS, Rigo O, Germain L, Godet SS (2016) Electron beam melted Ti6Al4V: microstructure, texture and mechanical behavior of the as-built and heat-treated material. Mater Sci Eng A 652:105–119

Ek RK, Rännar L-E, Bäckstöm M, Carlsson P (2016) The effect of EBM process parameters upon surface roughness. Rapid Prototyp J 19-3:173–179

Everhart W, Dinardo J, Barr C (2017) The effect of scan length on the structure and mechanical properties of electron beam-melted Ti6Al4V. Metall Mater Trans A Phys Metall Mater Sci 48-2:697–705

Fiocchi J, Biffi CA, Scaccabarozzi D, Saggin B, Tuissi A (2019) Enhancement of the damping behavior of Ti6Al4V alloy through the use of trabecular structure produced by selective laser melting. Adv Eng Mater. https://doi.org/10.1002/adem.201900722

Fotovvati B, Etesami SA, Asadi E (2019) Process-property-geometrycorrelationsforadditively-manufactured Ti–6Al–4Vsheets. Mater Sci Eng A 760:431–447

Galarraga H, Lados DA, Dehoff RR, Kirka MM, Nandwana P (2016) Effects of heat treatments on microstructure and properties of Ti6Al4V ELI alloy fabricated by electron beam melting (EBM). Addit Manuf 10:47–57

Galarragaa HC, Warren RJ, Ladosa DA, Dehoffb RR, Kirkab MM, Nandwanab CP (2017) Effects of heat treatments on microstructure and properties of Ti6Al4V ELI alloy fabricated by electron beam melting (EBM). Mater Sci Eng A 865-8:417–428

Gong H, Rafi K, Starr T, Stucker B (2013) The effects of processing parameters on defect regularity in Ti-6Al4V parts fabricated by selective laser melting. 24th annual international solid freeform fabrication symposium—an additive manufacturing conference, Austin, TX

Gong X, Lydon J, Cooper K, Chou K (2014) Beam speed effects on Ti6Al4V microstructures in electron beam additive manufacturing. J Mater Res 29-17:1951–1959

Guo C, Ge W, Lin F (2015) Effects of scanning parameters on material deposition during electron beam selective melting of Ti6Al4V powder. J Mater Process Technol 217:148–157

Hrabe N, Quinn T (2013) Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti-6Al-4V) fabricated using electron beam melting (EBM), part 1: distance from build plate and part size. Mater Sci Eng A 573:264–270

Jamshidinia M, Kong F, Kovacevic R (2013) Numerical modeling of heat distribution in the electron beam melting of Ti6Al4V. J Manuf Sci Eng 135-6:061010

Khorasani AM, Gibson I, Ghaderi A, Mohammed MI (2019) Investigation on the effect of heat treatment and process parameters on the tensile behaviour of SLM Ti-6Al-4V parts. Int J Adv Manuf Technol 101(9–12):3183–3197

Klassen A, Bauereiß A, Korner C (2014) Modelling of electron beam absorption. J Phys D 47-6:065307

Narra SP, Cunningham R, Beuth J, Rollett AD (2018) Location specific solidification microstructure control in electron beam melting of Ti-6Al-4V. Addit Manuf 19:160–166

Price S, Cheng B, Lydon J, Cooper K (2014) On process temperature in powder bed electron beam additive manufacturing: process parameter effects. J Manuf Sci E-T ASME 136-6:061019–061011

Safdar A, He HZ, Wei L-Y, Snis A, Chavez de Paz LE (2012a) Effect of process parameters settings and thickness on surface roughness of EBM produced Ti-6Al-4V. Rapid Prototyp J 18(5):401–408

Safdar A, Wei L-YY, Snis A, Lai Z (2012b) Evaluation of microstructural development in electron beam melted Ti6Al4V. Mater Charact 65:8–15

Schur R (2019) Effects of powder reuse on the mechanical properties of electron beam additively manufactured Ti-6Al-4V (doctoral dissertation)

Sun YY, Gulizia S, Fraser D, Oh CH, Lu SL, Qian M (2017) Layer additive production or manufacturing of thick sections of Ti6Al4V by selective electron beam melting (SEBM). Jom. 69-10:1836–1843

Tammas-Williams S, Zhao H, Léonard F, Derguti F, Todd I, Prangnell PB (2015) XCT analysis of the influence of melt strategies on defect population in Ti6Al4V components manufactured by selective electron beam melting. Mater Charact 102:47–61

Tan X, Kok Y, Tan YJ, Descoins M, Mangelinck D, Tor SB, Leong KF, Chua CK (2015) Graded microstructure and mechanical properties of additive manufactured Ti6Al4V via electron beam melting. Acta Mater 97:1–16

Tang HP, Qian M, Liu N, Zhang XZ, Yang GY, Wang J (2015) Effect of powder reuse times on additive manufacturing of Ti-6Al-4V by selective electron beam melting. Jom 67(3):555–563

Vayre B, Vignat F, Villeneuve F (2013) Identification on some design key parameters for additive manufacturing: application on electron beam melting. Procedia CIRP 7:264–269

Wei C, Ma X, Yang X, Zhou M, Wang C, Zheng Y, Zhang W, Li Z (2018) Microstructural and property evolution of Ti6Al4V powders with the number of usage in additive manufacturing by electron beam melting. Mater Lett 221:111–114

Zaeh MF, Kahnert ÆM (2009) The effect of scanning strategies on electron beam sintering. Prod Eng 3-3:217–224

Acknowledgments

The authors wish to express their gratitude to Mahr GbmH and CMF Marelli for their support with the surface metrology equipment.

Funding

The authors acknowledge Accordo Quadro CNR/Regione Lombardia n. 3866 in 17/07/2015 FHfFC program for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Biffi, C.A., Fiocchi, J., Ferrario, E. et al. Effects of the scanning strategy on the microstructure and mechanical properties of a TiAl6V4 alloy produced by electron beam additive manufacturing. Int J Adv Manuf Technol 107, 4913–4924 (2020). https://doi.org/10.1007/s00170-020-05358-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05358-y