Abstract

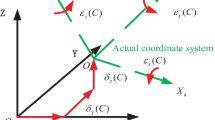

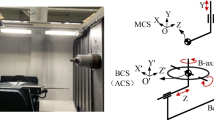

The geometric errors of rotary axes are crucial error sources of a five-axis machine tool. They directly affect the machining accuracy, and therefore become one of the most important items for accuracy design. In this paper, a prediction and identification method for the geometric errors of rotary axes on a five-axis machine tool is proposed. The prediction is realized by calculating the mapping relationship between tolerances and geometric errors of rotary axes, which is based on exploring rotary axes’ motion regulation and Fourier series fitting. Then in order to figure out the practical geometric errors of rotary axes, the identifying model is established based on homogeneous transform matrix (HTM). Double ball-bar (DBB) is adopted to test error motions of rotary axes. Finally, a demonstration experiment has been conducted for verifying the effectiveness and precision of the proposed prediction model. The experimental results show that the predicting model is able to reflect the motion principle of rotary axes’ kinematic errors. The SSE, which expresses residual sum of squares between estimated value and identified point, of εz(c),δx(c),εy(c),δz(c),εx(c), and δy(c), are 7.7716 × 10−11, 1.2064 × 10−4, 2.7838 × 10−10, 2.9639 × 10−7, 1.8966 × 10−10, and 2.7838 × 10−10, respectively. And R2, who represent fitting equation’s coefficient of determination, of abovementioned geometric errors, are 0.8978, 0.9876, 0.9978, 0.9453, 0.9985, and 0.9978, respectively. The computing results show that two kinds of curves are basically coincide, and the proposed method is proven to be feasibility.

Similar content being viewed by others

References

Bi QZ, Huang ND, Sun C, Wang YH, Zhu LM, Ding H (2015) Identification and compensation of geometric errors of rotary axes on five-axis machine by on-machine measurement. Int J Mach Tools Manuf 89:182–191. https://doi.org/10.1016/j.ijmachtools.2014.11.008

Nojehdeh MV, Arezoo B (2016) Functional accuracy investigation of work-holding rotary axes in five-axis CNC machine tools. Int J Mach Tools Manuf 111:17–30. https://doi.org/10.1016/j.ijmachtools.2016.09.002

Ma Y (2001) Sensor placement optimization for thermal error compensation on machine tools [D]. University of Michigan, Ann Arbor

Li H, Li YG, Mou WP, Hao XZ, Li ZX, Jin Y (2017) Sculptured surface-oriented machining error synthesis modeling for five-axis machine tool accuracy design optimization. Int J Adv Manuf Technol 89:3285–3298. https://doi.org/10.1007/s00170-016-9285-x

Fu GQ, Fu JZ, Xu YT, Chen ZC, Lai JT (2015) Accuracy enhancement of five-axis machine tool based on differential motion matrix: geometric error modeling, identification and compensation. Int J Mach Tools Manuf 89:170–181. https://doi.org/10.1016/j.ijmachtools.2014.11.005

Lee K, Yang SH (2013) Measurement and verification of position-independent geometric errors of a five-axis machine tool using a double ball-bar. Int J Mach Tools Manuf 70:45–52. https://doi.org/10.1016/j.ijmachtools.2013.03.010

Schwenke H, Knapp W, Haitjema H, Weckenmann A, Schmitt R, Delbressine F (2008) Geometric error measurement and compensation of machines-an update. CIRP Ann 57:660–675. https://doi.org/10.1016/j.cirp.2008.09.008

Lasemi A, Xue DY, Gu PH Accurate identification and compensation of geometric errors of 5-axis CNC machine tools using double ball bar. Meas Sci Technol 27:055004(18pp). https://doi.org/10.1088/0957-0233/27/5/055004

Chen GD, Liang YC, Sun YZ (2013) Volumetric error modeling and sensitivity analysis for designing a five-axis ultra-precision machine tool. Int J Adv Manuf Technol 68:2525–2534. https://doi.org/10.1007/s00170-013-4874-4

Ramesh R, Mannan MA, Poo AN (2000) Error compensation in machine tools—a review: Part I: geometric, cutting-force induced and fixture-dependent errors. Int J Mach Tools Manuf 40:1235–1256. https://doi.org/10.1016/S0890-6955(00)00009-2

JiangXG CRJ (2015) A method of testing position independent geometric errors in rotary axes of a five-axis machine tool using a double ball bar. Int J Mach Tools Manuf 89:151–158. https://doi.org/10.1016/j.ijmachtools.2014.10.010

Lei WT, Wang WC, Fang TC (2014) Ballbar dynamic tests for rotary axes of five-axis CNC machine tools. Int J Mach Tools Manuf 82-83:29–41. https://doi.org/10.1016/j.ijmachtools.2014.03.008

Ding S, Huang XD, Yu CJ, Wang W (2016) Actual inverse kinematics for position-independent and position-dependent geometric error compensation of five-axis machine tools. Int J Mach Tools Manuf 111:55–62. https://doi.org/10.1016/j.ijmachtools.2016.10.001

He ZY, Fu JZ, Zhang LC, Yao XH (2015) A new error measurement method to identify all six error parameters of a rotational axis of a machine tool. Int J Mach Tools Manuf 88:1–8. https://doi.org/10.1016/j.ijmachtools.2014.07.009

Xiang ST, Yang JG, Zhang Y (2014) Using a double ball bar to identify position-independent geometric errors on the rotary axes of five-axis machine tools. Int J Adv Manuf Technol 70:2071–2082. https://doi.org/10.1007/s00170-013-5432-9

Xia HJ, Peng WC, Ouyang XB, Chen XD, Wang SJ, Chen X (2017) Identification of geometric errors of rotary axis on multi-axis machine tool based on kinematic analysis method using double ball bar. Int J Mach Tools Manuf 122:161–175. https://doi.org/10.1016/j.ijmachtools.2017.07.006

Abbaszadeh-Mir Y, Mayer JRR, Cloutier G, Fortin C (2010) Theory and simulation for the identification of the link geometric errors for a five-axis machine tool using a telescoping magnetic ball-bar. Int J Prod Res 40:4781–4797. https://doi.org/10.1080/00207540210164459

Qiao Y, Chen YP, Yang JX, Chen B (2017) A five-axis geometric errors calibration model based on the common perpendicular line (CPL) transformation using the product of exponentials (POE) formula. Int J Mach Tools Manuf 118-119:49–60. https://doi.org/10.1016/j.ijmachtools.2017.04.003

Zhang Y, Yang JG, Zhang K (2013) Geometric error measurement and compensation for the rotary table of five-axis machine tool with double ballbar. Int J Adv Manuf Technol 65:275–281. https://doi.org/10.1007/s00170-012-4166-4

Chen JX, Lin SW, Zhou XL, Gu TQ (2016) A ballbar test for measurement and identification the comprehensive error of tilt table. Int J Mach Tools Manuf 103:1–12. https://doi.org/10.1016/j.ijmachtools.2015.12.002

Jiang L, Ding GF, Li Z, Zhu SW, Qin SF (2012) Geometric error model and measuring method based on worktable for five-axis machine tools. J Eng Manuf 227:32–44. https://doi.org/10.1177/0954405412462944

ISO230-2 (2006) Test code for machine tools-Part 2:Determination of accuracy and repeatability of positioning of numerically controlled axes

Fu GQ, Fu JZ, Shen HY, Xu YT, Jin YA (2015) Product-of-exponential formulas for precision enhancement of five-axis machine tools via geometric error modeling and compensation. Int J Adv Manuf Technol 81:289–305. https://doi.org/10.1007/s00170-015-7035-0

Lu XD, Jamalian A (2011) A new method for characterizing axis of rotation radial error motion: part 1. Two-dimensional radial error motion theory. Precis Eng 35:73–94. https://doi.org/10.1016/j.precisioneng.2010.08.005

Wu CJ, Fan JW, Wang QH, Chen DJ (2018) Machining accuracy improvement of non-orthogonal five-axis machine tools by a new iterative compensation methodology based on the relative motion constraint equation. Int J Mach Tools Manuf 124:80–98. https://doi.org/10.1016/j.ijmachtools.2017.07.008

Fan JW, Tao HH, Wu CJ, Pan R, Tang YH, Li ZS (2018) Kinematic errors prediction for multi-axis machine tools’ guideways based on tolerance. Int J Adv Manuf Technol 98:1131–1144. https://doi.org/10.1007/s00170-018-2335-9

Wu CJ, Fan JW, Wang QH, Pan R, Tang YH, Li ZS (2018) Prediction and compensation of geometric error for translational axes in multi-axis machine tools. Int J Adv Manuf Technol 95:3413–3435. https://doi.org/10.1007/s00170-017-1385-8

Lee K, Lee DM, Yang SH (2012) Parametric modeling and estimation of geometric errors for a rotary axis using double ball-bar. Int J Adv Manuf Technol 62:741–750. https://doi.org/10.1007/s00170-011-3834-0

Ekinci TO, Mayer JRR (2007) Relationships between straightness and angular kinematic errors in machines. Int J Mach Tools Manuf 47:1997–2004. https://doi.org/10.1016/j.ijmachtools.2007.02.002

ISO 841 (2001) Industrial automation systems and integration: Numerical control of machines: coordinate system and motion nomenclature

Lee K, Yang SH (2013) Robust measurement method and uncertainty analysis for position-independent geometric errors of a rotary axis using a double ball-bar. Int J Precis Eng 14:231–239. https://doi.org/10.1007/s12541-013-0032-z

ISO 230-7 (2015) Test code for machine tools-Part 7: geometric accuracy of axes of rotation

ANSI/ASME B89.3.4M (1985) Axis of rotation: methods for specifying and testing

ISO 230-1 (2012). Test code for machine tools-Part 1: geometric accuracy of machines operating under no-load or quasi-static conditions

Chen YT, More P, Liu CS, Cheng CC (2019) Identification and compensation of position-dependent geometric errors of rotary axes on five-axis machine tools by using a touch-trigger probe and there spheres. Int J Adv Manuf Technol 102:3077–3089. https://doi.org/10.1007/s00170-019-03413-x

Acknowledgments

The authors would also like to thank Changjun Wu, Haohao Tao, and Kaiyu Song for their helpfulness during the writing.

Funding

The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (No. 51775010 and 52175014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fan, J., Zhang, Y. A novel methodology for predicting and identifying geometric errors of rotary axis in five-axis machine tools. Int J Adv Manuf Technol 108, 705–719 (2020). https://doi.org/10.1007/s00170-020-05331-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05331-9