Abstract

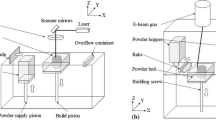

The nature of additive manufacturing (AM) processes prescribes direction-dependent properties of the final parts. The degree of material anisotropy is highly dependent on the process parameters and the machine setup which complicates the design of AM parts. A basic problem in the design and quality control of parts and components manufactured by the AM processes is the evaluation of the resulting elastic properties, specifically along the principal directions. In a destructive testing approach, many specimens in the principal directions are normally required to determine the elastic properties of a material. However, an alternative low-cost method based on the ultrasonic wave propagation velocities can also be used for this purpose. In this article, an ultrasonic-based method for the determination of the elastic constants of the Inconel 625 (IN625) material as manufactured via the laser powder-bed fusion process (L-PBF) is presented. Several specimens are fabricated with various process parameters such as laser power, scan speed, and hatch spacing, and nondestructively tested. The material elastic constants are then determined by measuring the ultrasonic wave velocities within the specimen. The results are verified qualitatively with the published results and destructive tensile tests. The obtained results showed a good correlation indicating the effectiveness of the proposed method for the determination of elastic constants of additively manufactured IN625 material.

Similar content being viewed by others

References

Sola A, Nouri A (2019) Microstructural porosity in additive manufacturing: the formation and detection of pores in metal parts fabricated by powder bed fusion. J Adv Manuf Process 1(3):1–21. https://doi.org/10.1002/amp2.10021

Liverani E, Toschi S, Ceschini L, Fortunato A (2017) Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J Mater Process Technol 249:255–263. https://doi.org/10.1016/j.jmatprotec.2017.05.042

Pal S, Gubeljak N, Hudak R, Lojen G, Rajtukova V, Predan J, Kokol V, Drstvensek I (2019) Tensile properties of selective laser melting products affected by building orientation and energy density. Mat Sci Eng A 743:637–647. https://doi.org/10.1016/j.msea.2018.11.130

Hovig EW, Azar AS, Grytten F, Sørby K, Andreassen E (2018) Determination of anisotropic mechanical properties for materials processed by laser powder bed fusion. Adv Mater Sci Eng 2018:7650303, 20 pages. https://doi.org/10.1155/2018/7650303

Kok Y, Tan XP, Wang P, Nai MLS, Loh NH, Liu E, Tor SB (2018) Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: a critical review. Mater Des 139:565–586. https://doi.org/10.1016/j.matdes.2017.11.021

Hitzler L, Hirsch J, Heine B, Merkel M, Hall W, Öchsner A (2017) On the anisotropic mechanical properties of selective laser-melted stainless steel. Materials 10:1136. https://doi.org/10.3390/ma10101136

Jalili MM, Pirayeshfar AS, Mousavi SY (2010) Non-destructive acoustic test (NDAT) to determine elastic modulus of polymeric composites. In: EWGAE 2010, Vienna, 8th to 10th September

Alfano M, Pagnotta L (2006) Determining the elastic constants of isotropic materials by modal vibration testing of rectangular thin plates. J Sound Vib 293(1–2):426–439. https://doi.org/10.1016/j.jsv.2005.10.021

Frederiksen PS (1997) Experimental procedure and results for the identification of elastic constants of thick orthotropic plates. J Compos Mater 31(4):360–382. https://doi.org/10.1177/002199839703100403

Gonzalez JA, Mireles J, Stafford SW, Perez MA, Terrazas CA, Wicker RB (2019) Characterization of Inconel 625 fabricated using powder-bed-based additive manufacturing technologies. J Mater Process Technol 264:200–210. https://doi.org/10.1016/j.jmatprotec.2018.08.031

EOS Nickel Alloy IN625 Material Data Sheet. Electro Optical Systems. https://dmlstechnology.com/images/pdf/EOS_NickelAlloy_IN625.pdf

Khan SZ, Khan TM, Joya YF, Khan MA, Ahmed S, Shah A (2015) Assessment of material properties of AISI 316L stainless steel using non-destructive testing. Nondestruct Test Eva 31(4):1–11. https://doi.org/10.1080/10589759.2015.1121265

Hu E, Wang W (2016) The elastic constants measurement of metal alloy by using ultrasonic nondestructive method at different temperature. Math Probl Eng 2016:6762076–6762077. https://doi.org/10.1155/2016/6762076

Van Buskirk WC, Cowin SC, Ward RN (1981) Ultrasonic measurement of orthotropic elastic constants of bovine femoral bone. J Biomech Eng 103:67–72. https://doi.org/10.1115/1.3138262

Liao JJ, Hu T-B, Chang C-W (1997) Determination of dynamic elastic constants of transversely isotropic rocks using a single cylindrical specimen. Int J Rock Mech Min 34(7):1045–1054. https://doi.org/10.1016/S1365-1609(97)90198-2

Svitek T, Vavryčuk V, Lokajíáek T, Petružálek M (2014) Determination of elastic anisotropy of rocks from P- and S-wave velocities: numerical modelling and lab measurements. Geophys J Int 199:1682–1697. https://doi.org/10.1093/gji/ggu332

Mistou S, Karama M (2000) Determination of the elastic properties of composite materials by tensile testing and ultrasound measurement. J Compos Mater 34(20):1696–1709. https://doi.org/10.1106/UY4R-FG3H-HKGW-UD3Q

Mah M, Schmitt DR (2003) Determination of the complete elastic stiffnesses from ultrasonic phase velocity measurements. J Geophys Res 108(B1):ECV 6-1–ECV 6-11. https://doi.org/10.1029/2001JB001586

Wong RCK, Schmitt DR, Collis D, Gautam R (2008) Inherent transversely isotropic elastic parameters of over-consolidated shale measured by ultrasonic waves and their comparison with static and acoustic in situ log measurements. J Geophys Eng 5:103–117. https://doi.org/10.1088/1742-2132/5/1/011

Gonҫalves R, Júnior MG, Lopes IM (2011) Determining the concrete stiffness matrix through ultrasonic testing. Eng Agríc Jaboticabal 31(3):427–437. https://doi.org/10.1590/S0100-69162011000300003

Crespo J, Aira JR, Vázquez C, Guaita M (2017) Comparative analysis of the elastic constants measured via conventional ultrasound, and 3-D digital image correlation methods in eucalyptus globulus labill. BioResources 12(2):3728–3743. https://doi.org/10.15376/biores.12.2.3728-3743

Foster DR, Dapino MJ, Babu SS (2013) Elastic constants of ultrasonic additive manufactured AL 3003-H18. Ultrasonics 53:211–218. https://doi.org/10.1016/j.ultras.2012.06.002

Webersen M, Johannesmann S, Düchting J, Claes L, Henning B (2018) Guided ultrasonic waves for determining effective orthotropic material parameters of continuous-fiber reinforced thermoplastic plates. Ultrasonics 84:53–62. https://doi.org/10.1016/j.ultras.2017.10.005

Castellano A, Foti P, Fraddosio A, Marzano S, Piccioni MD (2014) Mechanical characterization of CFRP composites by ultrasonic immersion tests: experimental and numerical approaches. Comp B: Eng 66:299–310. https://doi.org/10.1016/j.compositesb.2014.04.024

Paterson DAP, Ijomah W, Windmill JFC (2018) Elastic constant determination of unidirectional composite via ultrasonic bulk wave through transmission measurements: a review. Prog Mater Sci 97:1–37. https://doi.org/10.1016/j.pmatsci.2018.04.001

Zhan Y, Liu C, Kong X, Li Y (2018) Measurement of fiber reinforced composite engineering constants with laser ultrasonic. Appl Acoust 139:182–188. https://doi.org/10.1016/j.apacoust.2018.04.036

Kersemans M, Martens A, Lammens N, Van Den Abeele K, Degrieck J, Zastavnik F, Pyl L, Sol H, Van Paepegem W (2014) Identification of the elastic properties of isotropic and orthotropic thin-plate materials with the pulsed ultrasonic polar scan. Exp Mech 54:1121–1132. https://doi.org/10.1007/s11340-014-9861-7

Shukla A (2019) Determination of elastic constants of Inconel-625 superalloy, using laser-based ultrasonic. J Theor Appl Phys 13:49–54. https://doi.org/10.1007/s40094-018-0311-2

Amado-Becker A, Ramos-Grez J, Yañez MJ, Vargas Y, Gaete L (2008) Elastic tensor stiffness coefficients for SLS Nylon 12 under different degrees of densification as measured by ultrasonic technique. Rapid Prototyp J 14(5):260–270. https://doi.org/10.1108/13552540810907929

Malefane LB, du Preez WB, Maringa M (2016) Testing for homogeneity and orthotropy of Ti6Al4V (ELI) parts built by Direct Metal Laser Sintering. In: 17th Annual Conference of the Rapid Product Development Association of South Africa

Van Buskirk WC, Cowin SC, Carter R Jr (1986) A theory of acoustic measurement of the elastic constants of a general anisotropic solid. J Mater Sci 21:2759–2762. https://doi.org/10.1007/BF00551484

Summerscales J (2000) The bulk modulus of carbon fibers. J Mater Sci Lett 19:15–16. https://doi.org/10.1023/A:1006731210592

Criales LE, Arısoy YM, Lane B, Moylan S, Donmez A, Özel T (2017) Laser powder bed fusion of nickel alloy 625: experimental investigations of effects of process parameters on melt pool size and shape with spatter analysis. Int J Mach Tool Manu 121:22–36. https://doi.org/10.1016/j.ijmachtools.2017.03.004

ASME (2013) STD Sec V Article IV. American Society of Mechanical Engineers

Anam MA, Pal D, Stucker B (2013) Modeling and experimental validation of nickel-based super alloy (Inconel 625) made using selective laser melting. In: Proceeding of the 24th Annual International Solid Free form Fabrication Symposium-An Additive Manufacturing Conference, Austin, TX, USA, 463–473. https://doi.org/10.13140/2.1.4009.1201

Chen X, Schmitt DR, Kessler JA, Evans J, Kofman R (2015) Empirical relations between ultrasonic P-wave velocity, porosity and uniaxial compressive strength. CSEG RECORDER 40(5):24–29

Chawre B (2018) Correlations between ultrasonic pulse wave velocities and rock properties of quartz-mica schist. J Rock Mech Geotech Eng 10(3):594–602. https://doi.org/10.1016/j.jrmge.2018.01.006

Manoylov AV, Borodich FM, Evans HP (2013) Modelling of elastic properties of sintered porous materials. P Roy Soc A 469:20120689. https://doi.org/10.1098/rspa.2012.0689

Gong H, Rafi K, Gu H, Janaki Ram GD, Starr T, Stucker B (2015) Influence of defects on mechanical properties of Ti-6Al-4V components produced by selective laser melting and electron beam melting. Mater Des 86:545–554. https://doi.org/10.1016/j.matdes.2015.07.147

Bräunig J, Töppel T, Müller B, Burkhardt M, Hipke T, Drossel W-G (2014) Advanced material studies for additive manufacturing in terms of future gear application. Adv Mech Eng 10 pages. https://doi.org/10.1155/2014/741083

Brown CU, Jacob G, Stoudt M, Moylan S, Slotwinski J, Donmez A (2016) Interlaboratory study for nickel alloy 625 made by laser powder bed fusion to quantify mechanical property variability. J Mater Eng Perform 25(8):3390–3397. https://doi.org/10.1007/s11665-016-2169-2

Arnold M, Boccaccini AR, Ondracek G (1996) Prediction of the Poisson’s ratio of porous materials. J Mater Sci 31(6):1643–1646. https://doi.org/10.1007/BF00357876

ASTM F 3056: Standard specification for additive manufacturing nickel alloy (UNS N06625) with powder bed fusion, ASTM (2014)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Javidrad, H.R., Salemi, S. Determination of elastic constants of additive manufactured Inconel 625 specimens using an ultrasonic technique. Int J Adv Manuf Technol 107, 4597–4607 (2020). https://doi.org/10.1007/s00170-020-05321-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05321-x