Abstract

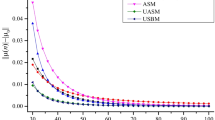

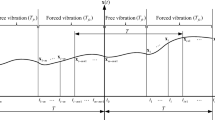

To address the vibration phenomenon in the milling process, this study proposed an implicit Adams method (IAM) to predict the stability of the milling process. The dynamic equation of milling process with regenerative chatter can be expressed as a delay linear differential equation. The cutter tooth cycle can be divided into the forced and free vibration stages. The forced vibration stage is discretized and IAM is used to construct state transition matrix. The stability of the system is determined based on Floquet theory and the stability lobe diagrams are obtained. Matlab simulation and experiment results show that IAM is an effective method to predict the stability of milling. First, compared with the typical discretization methods, the IAM method indicates a faster convergence rate. Next, in one- and two-degree freedom dynamic model, the stability lobe diagrams show that the prediction accuracy and computation efficiency of IAM are better than that of the first-order semi-discretization method (1st-SDM), second-order full discretization method (2nd-FDM), and the Simpson method (SIM). Finally, acceleration signals collected from cutting experiments are analyzed by mathematical statistics, time-domain method, and frequency-domain method. It is concluded that the simulation results are consistent with the experimental analysis results which verifies the effectiveness of IAM.

Similar content being viewed by others

References

Wiercigroch M, Budak E (2001) Sources of nonlinearities, chatter generation and suppression in metal cutting. Philos Trans R Soc A Math Phys Eng Sci 359(1781):663–693

Kayhan M, Budak E (2009) An experimental investigation of chatter effects on tool life. Proc IME B J Eng Manuf 223(11):1455–1463

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann Manuf Technol 53(2):619–642

Balachandran B (2001) Nonlinear dynamics of milling processes. Philos Trans Math Phys Eng Sci 359(1781):793–819

Budak E (1998) Analytical prediction of chatter stability in milling-part I: general formulation. J Dyn Syst Meas Control 120(1):31–36

Altintas Y, Budak E (1995) Analytical prediction of stability lobes in milling. CIRP Ann Manuf Technol 44(1):357–362

Merdol SD, Altintas Y (2004) Multi frequency solution of chatter stability for low immersion milling. J Manuf Sci Eng 126(3):459

Insperger T, Stepan G (2002) Semi-discretization method for delayed systems. Int J Numer Methods Eng 55(5):503–518

Insperger T, Stepan G (2004) Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int J Numer Methods Eng 61(1):117–141

Insperger T, Stepan G, Turi J (2015) On the higher-order semi-discretizations for periodic delayed systems. J Sound Vib 313(1):334–341

Long XH, Balachandran B (2007) Stability analysis for milling process. Nonlinear Dyn 49(3):349–359

Long XH, Balachandran B, Mann BP (2007) Dynamics of milling processes with variable time delays. Nonlinear Dyn 47(1–3):49–63

Li ZW, Long XH, Meng G (2009) Semi-discrete analytical method for the stability of milling system based on Magnus-Gaussian truncation. J Vib Shock 28(5):69–73

Jiang SL, Sun YW, Yuan XL, Liu WR (2017) A second-order semi-discretization method for the efficient and accurate stability prediction of milling process. Int J Adv Manuf Technol 92:583–595

Dong XF, Zhang WM, Deng S (2015) The reconstruction of a semi-discretization method for milling stability prediction based on Shannon standard orthogonal basis. Int J Adv Manuf Technol 85(5–8):1501–1511

Butcher EA, Ma H, Bueler E, Averina V, Szabo Z (2004) Stability of linear time-periodic delay-differential equations via Chebyshev polynomials. Int J Numer Methods Eng 59(7):895–922

Butcher EA, Bobrenkov OA, Bueler E, Nindujarla P (2009) Analysis of milling stability by the Chebyshev collocation method algorithm and optimal stable immersion levels. J Comput Nonlinear Dyn 4(3):340–341

Yan ZH, Wang XB, Liu ZB, Wang DQ, Ji YJ, Li J (2017) Orthogonal polynomial approximation method for stability prediction in milling. Int J Adv Manuf Technol 91:4313–4330

Ding Y, Zhu LM, Zhang XJ, Ding H (2010) A full-discretization method for prediction of milling stability. Int J Mach Tools Manuf 50(5):502–509

Ding Y, Zhu LM, Zhang XJ, Ding H (2010) Second-order full-discretization method for milling stability prediction. Int J Mach Tool Manu 50:926–932

Quo Q, Sun Y, Jiang Y (2012) On the accurate calculation of milling stability limits using third-order full-discretization method. Int J Mach Tool Manu 62(1):61–66

Li MZ, Zhang GJ, Huang Y (2013) Complete discretization scheme for milling stability prediction. Nonlinear Dyn 71(1–2):187–199

Ji YJ, Wang XB, Liu ZB, Wang HJ, Yan ZH (2018) An updated full-discretization milling stability prediction method based on the higher-order Hermite-Newton interpolation polynomial. Int J Adv Manuf Technol 95(5–8):2227–2242

Tang XW, Peng FY, Yan R, Gong YH, Li YT, Jiang LL (2017) Accurate and efficient prediction of milling stability with updated full-discretization method. Int J Adv Manuf Technol 88:2357–2368

Xie, Q Z. Milling stability prediction using an improved complete discretization method. Int J Adv Manuf Technol, 2016, 83(5–8):815–821

Ding Y, Zhu LM, Zhang XJ, Ding H (2011) Numerical integration method for prediction of milling stability. J Manuf Sci Eng 133(3):255–267

Ding Y, Zhu LM, Zhang XJ, Ding H (2011) Milling stability analysis using the spectral method. Sci China Technol Sci 54(12):3130–3136

Niu JB, Ding Y, Zhu LM, Ding H (2014) Runge–Kutta methods for a semi-analytical prediction of milling stability. Nonlinear Dyn 76(1):289–304

Li HK, Dai YB, Fan ZF (2019) Improved precise integration method for chatter stability prediction of two-DOF milling system. Int J Adv Manuf Technol 101(1):1235–1246

Li ZQ, Yang ZK, Peng YR, Zhu F, Ming XZ (2016) Prediction of chatter stability for milling process using Runge-Kutta-based complete discretization method. Int J Adv Manuf Technol 86:943–952

Zhang Z, Li HG, Meng G, Liu C (2015) A novel approach for the prediction of the milling stability based on the Simpson method. Int J Mach Tools Manuf 99:43–47

Qin CJ, Tao JF, Li L, Liu CL (2017) An Adams-Moulton-based method for stability prediction of milling processes. Int J Adv Manuf Technol 89(9–2):3049–3058

Qin CJ, Tao JF, Li L, Liu CL (2017) Stability analysis for milling operations using an Adams-Simpson-based method. Int J Adv Manuf Technol 92(1–4):969–979

Zhang XJ, Xiong CH, Ding Y, Ding H (2016) Prediction of chatter stability in high speed milling using the numerical differentiation method. Int J Adv Manuf Technol 89(9–12):1–10

Grossi N, Montevecchi F, Sallese L, Scippa A, Campatelli G (2017) Chatter stability prediction for high-speed milling through a novel experimental-analytical approach. Int J Adv Manuf Technol 89:2587–2601

Funding

This work was partially supported by the National Natural Science Foundation of China under grant no. 51475317 and Natural Science Foundation of Shanxi Province under grant no. 201901D211285 and no. 201901D111237.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhi, H., Zhang, T., Du, J. et al. An efficient full-discretization method for milling stability prediction. Int J Adv Manuf Technol 107, 4955–4967 (2020). https://doi.org/10.1007/s00170-020-05290-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05290-1