Abstract

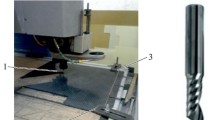

Carbon fiber-reinforced thermoplastics (CFRTP) have great interest nowadays due to their excellent mechanical properties and lightness. However, in opposition to thermoset matrix composites, there is a lake in the research about machining processes of these materials. Their low glass transition temperature is a handicap when conventional machining is used. An alternative is abrasive water jet machining (AWJM) because it does not cause thermal damage. However, the surface quality produced by this process must be studied and related to the cutting parameters. This article studies the surface quality generated by water jet machining in a low melting point thermoplastic matrix composite material. The kind of thermoplastic used is a TPU (polyurethane). The combination of a high-strength material (carbon fiber) with a low-strength material (thermoplastic matrix) makes machining difficult and can generate a poor surface finish. The influence of cutting parameters has been evaluated through an ANOVA analysis. A mathematical model that relates the surface quality with the cutting parameters has been established by means of a response surface methodology (RSM). The combination of a hydraulic pressure of 250 MPa with a traverse speed of 300 mm/min and an abrasive mass flow of 170 g/min produces the best surface quality. Finally, the main flaws when CFRTP is water jet machined have also been identified.

Similar content being viewed by others

Abbreviations

- \( \dot{m} \) a :

-

abrasive mass flow

- ANOVA:

-

analysis of variance

- AWJM:

-

abrasive water jet machining

- CFRP:

-

carbon fiber-reinforced plastics with thermoset matrix

- CFRTP:

-

carbon fiber-reinforced thermoplastics

- EAZ:

-

erosion affected zone

- EDS:

-

energy-dispersive X-ray spectroscopy

- P :

-

hydraulic pressure

- Ra:

-

arithmetic mean roughness

- RSM:

-

response surface methodology

- SEM:

-

scanning electron microscope

- TPU:

-

thermoplastic polyurethane

- UFFD:

-

ultrafast feed drilling

- UVD:

-

ultrasonic vibration-assisted drilling

- v :

-

traverse speed

References

Hashish M Trimming of Cfrp aircraft components. In: WJTA-IMCA Conference and Expo. Houston, Texas

Kumaran ST, Ko TJ, Uthayakumar M, Islam MM (2017) Prediction of surface roughness in abrasive water jet machining of CFRP composites using regression analysis. J Alloys Compd 724:1037–1045. https://doi.org/10.1016/j.jallcom.2017.07.108

Nor Khairusshima MK, Muhammad Hafiz Zakwan B, Suhaily M et al (2018) The optimization study on the tool wear of carbide cutting tool during milling carbon fibre reinforced (CFRP) using response surface methodology (RSM). IOP Conf Ser Mater Sci Eng 290:012068. https://doi.org/10.1088/1757-899X/290/1/012068

Masek P, Zeman P, Kolar P (2013) Development of a cutting tool for composites with thermoplastic matrix. Sci J:423–427

Franke V (2011) Drilling of long fiber reinforced thermoplastics - influence of the cutting edge on the machining results. CIRP Ann - Manuf Technol 60:65–68. https://doi.org/10.1016/j.cirp.2011.03.078

Masek P, Kolar P, Zeman P (2013) Optimization of trimming operations for machining carbon fibre reinforced thermoplastic composite. International Conference on Advanced Manufacturing Engineering and Technologies Optimization, In

Biron M (2018) Outline of the actual situation of plastics compared to conventional materials. In: William Andrew (ed) Thermoplastics and thermoplastic composites, 3rd ed. Norwich, pp 1–32

Goto K, Imai K, Arai M, Ishikawa T (2019) Shear and tensile joint strengths of carbon fiber-reinforced thermoplastics using ultrasonic welding. Compos Part A Appl Sci Manuf 116:126–137. https://doi.org/10.1016/j.compositesa.2018.10.032

Christmann M, Medina L, Mitschang P (2017) Effect of inhomogeneous temperature distribution on the impregnation process of the continuous compression molding technology. J Thermoplast Compos Mater 30:1285–1302. https://doi.org/10.1177/0892705716632855

Ishikawa T, Amaoka K, Masubuchi Y et al (2018) Overview of automotive structural composites technology developments in Japan. Compos Sci Technol 155:221–246. https://doi.org/10.1016/j.compscitech.2017.09.015

Tanaka K, Yamashiro T, Katayama T (2017) Internal damage evaluation of Cfrtp cut by a circular saw. Mater Contact Characterisation 116:345–351. https://doi.org/10.2495/MC170361

Henerichs M, Voß R, Tanaka H et al (2014) Analysis of material weakening in CFRP after a drilling operation. Procedia CIRP 24:44–48. https://doi.org/10.1016/j.procir.2014.07.145

Masek P, Zeman P, Kolar P (2018) Edge trimming of C/PPS plates. Int J Adv Manuf Technol 101:157–170. https://doi.org/10.1007/s00170-018-2857-1

Pahuja R, M. R (2019) Abrasive water jet machining of titanium (Ti6Al4V)–CFRP stacks – a semi-analytical modeling approach in the prediction of kerf geometry. J Manuf Process 39:327–337. https://doi.org/10.1016/j.jmapro.2019.01.041

Alberdi A, Artaza T, Suárez A et al (2016) An experimental study on abrasive waterjet cutting of CFRP/Ti6Al4V stacks for drilling operations. Int J Adv Manuf Technol 86:691–704. https://doi.org/10.1007/s00170-015-8192-x

Ruiz-Garcia R, Mayuet Ares P, Vazquez-Martinez J, Salguero Gómez J (2018) Influence of abrasive waterjet parameters on the cutting and drilling of CFRP/UNS A97075 and UNS A97075/CFRP stacks. Materials (Basel) 12:107. https://doi.org/10.3390/ma12010107

El-Hofy M, Helmy MO, Escobar-Palafox G et al (2018) Abrasive water jet machining of multidirectional CFRP laminates. Procedia CIRP 68:535–540. https://doi.org/10.1016/j.procir.2017.12.109

Ramulu M, Isvilanonda V, Pahuja R, Hashish M (2016) Experimental investigation of abrasive waterjet machining of titanium graphite laminates. Int J Autom Technol 10:392–400. https://doi.org/10.20965/ijat.2016.p0392

Melentiev R, Fang F (2018) Recent advances and challenges of abrasive jet machining. CIRP J Manuf Sci Technol. https://doi.org/10.1016/j.cirpj.2018.06.001

Momber AW, Kovacevic R (1998) Principles of abrasive water jet machining. Princ Abras Water Jet Mach. https://doi.org/10.1007/978-1-4471-1572-4

Mayuet PF, Girot F, Lamíkiz A et al (2015) SOM/SEM based characterization of internal delaminations of CFRP samples machined by AWJM. Procedia Eng 132:693–700. https://doi.org/10.1016/j.proeng.2015.12.549

Vigneshwaran S, Uthayakumar M, Arumugaprabu V (2017) Abrasive water jet machining of fiber-reinforced composite materials J Reinf Plast Compos 073168441774077. https://doi.org/10.1177/0731684417740771

Dhanawade A, Kumar S (2017) Experimental study of delamination and kerf geometry of carbon epoxy composite machined by abrasive water jet. J Compos Mater 51:3373–3390. https://doi.org/10.1177/0021998316688950

Ming Ming IW, Azmi AI, Chuan LC, Mansor AF (2017) Experimental study and empirical analyses of abrasive waterjet machining for hybrid carbon/glass fiber-reinforced composites for improved surface quality Int J Adv Manuf Technol 1–14. https://doi.org/10.1007/s00170-017-1465-9

Kumaran ST, Ko TJ, Kurniawan R, Li C, Uthayakumar M (2017) ANFIS modeling of surface roughness in abrasive waterjet machining of carbon fiber reinforced plastics. J Mech Sci Technol 31:3949–3954. https://doi.org/10.1007/s12206-017-0741-9

Ahmed TM, El Mesalamy AS, Youssef A, El Midany TT (2018) Improving surface roughness of abrasive waterjet cutting process by using statistical modeling. CIRP J Manuf Sci Technol. https://doi.org/10.1016/j.cirpj.2018.03.004

Jagadish BS, Ray A (2016) Prediction and optimization of process parameters of green composites in AWJM process using response surface methodology. Int J Adv Manuf Technol 87:1359–1370. https://doi.org/10.1007/s00170-015-8281-x

Jagadeesh B, Dinesh Babu P, Nalla Mohamed M, Marimuthu P (2017) Experimental investigation and optimization of abrasive water jet cutting parameters for the improvement of cut quality in carbon fiber reinforced plastic laminates J Ind Text 1–23. https://doi.org/10.1177/1528083717725911

Pahuja R, Ramulu M, Hashish M (2016) Abrasive waterjet profile cutting of thick titanium/graphite fiber metal laminate. Proc ASME 2016 Int Mech Eng Congr Expo IMECE2016 1–11. https://doi.org/10.1115/IMECE201667136

Kakinuma Y, Ishida T, Koike R et al (2015) Ultrafast feed drilling of carbon fiber-reinforced thermoplastics. Procedia CIRP 35:91–95. https://doi.org/10.1016/j.procir.2015.08.074

Mm IW, Azmi A, Lee C, Mansor A (2016) Kerf taper and delamination damage minimization of FRP hybrid composites under abrasive water-jet machining. Int J Adv Manuf Technol 94:1–18. https://doi.org/10.1007/s00170-016-9669-y

Ravi Kumar K, Sreebalaji VS, Pridhar T (2017) Characterization and optimization of abrasive water jet machining parameters of aluminium/tungsten carbide composites. Measurement. https://doi.org/10.1016/j.measurement.2017.11.059

Kumar A, Kumar V, Kumar J (2018) Investigation of machining characterization for wire wear ratio & MRR on pure titanium in WEDM process through response surface methodology. Proc Inst Mech Eng Part E J Process Mech Eng 232:108–126. https://doi.org/10.1177/0954408916685588

Singh T, Misra JP, Singh B (2017) Experimental investigation of influence of process parameters on MRR during WEDM of Al6063 alloy. Mater Today Proc 4:2242–2247. https://doi.org/10.1016/j.matpr.2017.02.071

M. R, Arola D (1994) The influence of abrasive waterjet cut/’ing conditions on the surface quality of graphite/epoxy laminates. 34:295–313

Ramalingam T, Bhaskar S, Seshumadhav K, Allamraju KV (2018) Optimization of process parameters in bi-directional carbon fiber composite using AWJM. Mater Today Proc 5:18933–18940. https://doi.org/10.1016/j.matpr.2018.06.243

Li M, Huang M, Chen Y et al (2019) Effects of processing parameters on kerf characteristics and surface integrity following abrasive waterjet slotting of Ti6Al4V/CFRP stacks. J Manuf Process 42:82–95. https://doi.org/10.1016/j.jmapro.2019.04.024

Axinte DA, Karpuschewski B, Kong MC et al (2014) High energy fluid jet machining (HEFJet-Mach): from scientific and technological advances to niche industrial applications. CIRP Ann-Manuf Technol 63:751–771. https://doi.org/10.1016/j.cirp.2014.05.001

Sutowski P, Sutowska M, Kapłonek W (2018) The use of high-frequency acoustic emission analysis for in-process assessment of the surface quality of aluminium alloy 5251 in abrasive waterjet machining. Proc Inst Mech Eng Part B J Eng Manuf 232:2547–2565. https://doi.org/10.1177/0954405417703428

Kalla DK, Dhanasekaran PS, Zhang B, Asmatulu R (2012) Abrasive waterjet machining of fiber reinforced composites: a review. AIP Conf Proc 1431:535–542. https://doi.org/10.1063/1.4707606

Shanmugam DK, Nguyen T, Wang J (2008) A study of delamination on graphite/epoxy composites in abrasive waterjet machining. Compos Part A Appl Sci Manuf 39:923–929. https://doi.org/10.1016/j.compositesa.2008.04.001

Alberdi A, Suárez A, Artaza T et al (2013) Composite cutting with abrasive water jet. Procedia Eng 63:421–429. https://doi.org/10.1016/j.proeng.2013.08.217

Köhler T, Röding T, Gries T, Seide G (2017) An overview of impregnation methods for carbon fibre reinforced thermoplastics. Key Eng Mater 742:473–481. https://doi.org/10.4028/www.scientific.net/KEM.742.473

Kumar D, Gururaja S (2019) Abrasive waterjet machining of Ti/CFRP/Ti laminate and multi-objective optimization of the process parameters using response surface methodology. J Compos Mater. https://doi.org/10.1177/0021998319884611

Pahuja R, Ramulu M, Hashish M (2019) Surface quality and kerf width prediction in abrasive water jet machining of surface quality and kerf width prediction in abrasive water jet machining of. Compos Part B 175:107134. https://doi.org/10.1016/j.compositesb.2019.107134

Azmir MA, Ahsan AK (2009) A study of abrasive water jet machining process on glass/epoxy composite laminate. J Mater Process Technol 209:6168–6173. https://doi.org/10.1016/j.jmatprotec.2009.08.011

Trujillo FJ, Sevilla L, Salguero J, Batista M, Marcos M (2013) Parametric potential model for determining the microgeometrical deviations of horizontally dry-turned UNS A97075 (Al-Zn) alloy. Adv Sci Lett 19:731–735. https://doi.org/10.1166/asl.2013.4818

Mayuet Ares PF, Rodríguez-Parada L, Gómez-Parra A, Batista M (2020) Characterization and defect analysis of machined regions in Al-SiC metal matrix composites using an abrasive water jet machining process. Appl Sci 10:1512

Sambruno A, Bañon F, Salguero J et al (2019) Kerf taper defect minimization based on abrasive waterjet machining of low thickness thermoplastic carbon fiber composites C / TPU. Materials (Basel) 12:1–17

Funding

This work has been developed under the support of a pre-doctoral industrial fellow financed by NANOTURES SL, the mechanical engineering, and industrial design department and the Vice-rectorate of Transference and Technological Innovation of the University of Cadiz.

Author information

Authors and Affiliations

Contributions

F.B. and A.S. developed machining tests. M.B. and J.S. developed data treatment. F.B., A.S., M.B., B.S., and J.S. analyzed the influence of the parameters involved. F.B. and A.S. collaborated in preparing figures and tables, and F.B., A.S., M.B., B.S., and J.S. wrote the paper.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bañon, F., Sambruno, A., Batista, M. et al. Study of the surface quality of carbon fiber–reinforced thermoplastic matrix composite (CFRTP) machined by abrasive water jet (AWJM). Int J Adv Manuf Technol 107, 3299–3313 (2020). https://doi.org/10.1007/s00170-020-05215-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05215-y