Abstract

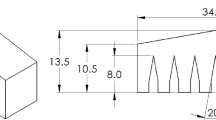

The increasing use of metal additive manufacturing (AM) technologies, such as direct metal laser sintering (DMLS), requires an in-depth understanding of how the optimum DMLS process parameters can be determined to achieve the target properties, such as reduced defect densities and/or desired surface characteristics. To this end, it is important to develop simple strategies that assess part quality and are fast and cost-effective. In this study, the in-plane surface roughness of components fabricated with AM is correlated with the DMLS process parameters and fractional density, enabling rapid and accurate indirect determination of the fractional density of AM components through surface roughness measurements. To this end, two sets of DMLS process parameters and a geometrical parameter are utilized to fabricate more than 150 rectangular cubic samples with varying parameters. All the samples are fabricated using Ti-6Al-4 V powder, which is a frequently used metal alloy for DMLS. Second, two line roughness parameters are defined and measured for all the samples, and their correlations with the DMLS and geometrical parameters are reported. Third, the fractional densities of all the samples are measured and their correlations with the DMLS process parameters are demonstrated. Lastly, a thorough analysis of the observed correlations between the line roughness parameters and fractional density are discussed.

Similar content being viewed by others

References

Spierings AB, Herres N, Levy G (2011) Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp J 17:195–202. https://doi.org/10.1108/13552541111124770

Grasso M, Colosimo BM (2017) Process defects and in situ monitoring methods in metal powder bed fusion: a review. Meas Sci Technol 28:044005. https://doi.org/10.1088/1361-6501/aa5c4f

Sanaei N, Fatemi A, Phan N (2019) Defect characteristics and analysis of their variability in metal L-PBF additive manufacturing. Mater Des 182:108091. https://doi.org/10.1016/J.MATDES.2019.108091

Greitemeier D, Dalle Donne C, Syassen F et al (2016) Effect of surface roughness on fatigue performance of additive manufactured Ti–6Al–4V. Mater Sci Technol 32:629–634. https://doi.org/10.1179/1743284715Y.0000000053

Fatemi A, Molaei R, Sharifimehr S et al (2017) Torsional fatigue behavior of wrought and additive manufactured Ti-6Al-4V by powder bed fusion including surface finish effect. Int J Fatigue 99:187–201. https://doi.org/10.1016/J.IJFATIGUE.2017.03.002

Fatemi A, Molaei R, Sharifimehr S et al (2017) Multiaxial fatigue behavior of wrought and additive manufactured Ti-6Al-4V including surface finish effect. Int J Fatigue 100:347–366. https://doi.org/10.1016/J.IJFATIGUE.2017.03.044

Pegues J, Roach M, Scott Williamson R, Shamsaei N (2018) Surface roughness effects on the fatigue strength of additively manufactured Ti-6Al-4V. Int J Fatigue 116:543–552. https://doi.org/10.1016/J.IJFATIGUE.2018.07.013

Edwards P, Ramulu M (2014) Fatigue performance evaluation of selective laser melted Ti–6Al–4V. Mater Sci Eng A 598:327–337. https://doi.org/10.1016/J.MSEA.2014.01.041

Wycisk E, Solbach A, Siddique S et al (2014) Effects of defects in laser additive manufactured Ti-6Al-4V on fatigue properties. Phys Procedia 56:371–378. https://doi.org/10.1016/J.PHPRO.2014.08.120

Chan KS, Koike M, Mason RL, Okabe T (2013) Fatigue life of titanium alloys fabricated by additive layer manufacturing techniques for dental implants. Metall Mater Trans A 44:1010–1022. https://doi.org/10.1007/s11661-012-1470-4

Calignano F (2018) Investigation of the accuracy and roughness in the laser powder bed fusion process. Virtual Phys Prototyp 13:97–104. https://doi.org/10.1080/17452759.2018.1426368

Song B, Dong S, Zhang B et al (2012) Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V. Mater Des 35:120–125. https://doi.org/10.1016/J.MATDES.2011.09.051

Debroy T, Wei HL, Zuback JS et al (2018) Additive manufacturing of metallic components-process, structure and properties. Prog Mater Sci 92:112–224. https://doi.org/10.1016/j.pmatsci.2017.10.001

Strano G, Hao L, Everson RM, Evans KE (2013) Surface roughness analysis, modelling and prediction in selective laser melting. J Mater Process Technol 213:589–597. https://doi.org/10.1016/J.JMATPROTEC.2012.11.011

Kruth JP, Vandenbroucke B, Van Vaerenbergh J, Naert I (2005) Rapid manufacturing of dental prostheses by means of selective laser sintering/melting. Proc AFPR S 4:176–186. https://ris.utwente.nl/ws/portalfiles/portal/5675573/Wa1025.pdf

Do DK, Li P (2016) The effect of laser energy input on the microstructure, physical and mechanical properties of Ti-6Al-4V alloys by selective laser melting. Virtual Phys Prototyp 11:41–47. https://doi.org/10.1080/17452759.2016.1142215

Simchi A (2006) Direct laser sintering of metal powders: mechanism, kinetics and microstructural features. Mater Sci Eng A 428:148–158. https://doi.org/10.1016/J.MSEA.2006.04.117

Mumtaz K, Hopkinson N (2009) Top surface and side roughness of Inconel 625 parts processed using selective laser melting. Rapid Prototyp J 15:96–103. https://doi.org/10.1108/13552540910943397

Yadroitsev I, Smurov I (2011) Surface morphology in selective laser melting of metal powders. Phys Procedia 12:264–270. https://doi.org/10.1016/J.PHPRO.2011.03.034

Tolochko NK, Mozzharov SE, Yadroitsev IA et al (2004) Balling processes during selective laser treatment of powders. Rapid Prototyp J 10:78–87. https://doi.org/10.1108/13552540410526953

Spierings AB, Levy G (2009) Comparison of density of stainless steel 316L parts produced with selective laser melting using different powder grades. In: Proceedings of the annual international solid freeform fabrication symposium. Austin, TX, pp 342–353

Mierzejewska ŻA, Hudák R, Sidun J et al (2019) Mechanical properties and microstructure of DMLS Ti6Al4V alloy dedicated to biomedical applications. Materials (Basel) 12:176. https://doi.org/10.3390/ma12010176

Badrossamay M, Yasa E, Van Vaerenbergh J, Kruth J-P (2009) Improving productivity rate in SLM of commercial steel powders. Tech Pap - Soc Manuf Eng TP09PUB17:1–13

Khorasani AM, Gibson I, Ghasemi A, Ghaderi A (2019) A comprehensive study on variability of relative density in selective laser melting of Ti-6Al-4V. Virtual Phys Prototyp 1–11. DOI https://doi.org/10.1080/17452759.2019.1614198

Rafi HK, Karthik NV, Gong H et al (2013) Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting. J Mater Eng Perform 22:3872–3883. https://doi.org/10.1007/s11665-013-0658-0

Gong H, Rafi K, Gu H et al (2014) Analysis of defect generation in Ti–6Al–4V parts made using powder bed fusion additive manufacturing processes. Addit Manuf 1–4:87–98. https://doi.org/10.1016/J.ADDMA.2014.08.002

Townsend A, Senin N, Blunt L et al (2016) Surface texture metrology for metal additive manufacturing: a review. Precis Eng 46:34–47. https://doi.org/10.1016/J.PRECISIONENG.2016.06.001

Townsend A, Racasan R, Blunt L (2018) Surface-specific additive manufacturing test artefacts. Surf Topogr Metrol Prop 6:024007. https://doi.org/10.1088/2051-672X/aabcaf

Kleszczynski S, Ladewig A, Friedberger K, Zur Jacobsmühlen J, Merhof D, Witt G (2015) Position dependency of surface roughness in parts from laser beam melting systems. In: 26th internation solid free form fabrication (SFF) symposium, Austin, TX, pp 10–12. https://www.lfb.rwth-aachen.de/bibtexupload/pdf/JAC15b.pdf

Triantaphyllou A, Giusca CL, Macaulay GD et al (2015) Surface texture measurement for additive manufacturing. Surf Topogr Metrol Prop 3:024002. https://doi.org/10.1088/2051-672X/3/2/024002

Fox JC, Moylan SP, Lane BM (2016) Effect of process parameters on the surface roughness of overhanging structures in laser powder bed fusion additive manufacturing. Procedia CIRP 45:131–134. https://doi.org/10.1016/J.PROCIR.2016.02.347

Yadroitsev I, Krakhmalev P, Yadroitsava I (2015) Hierarchical design principles of selective laser melting for high quality metallic objects. Addit Manuf 7:45–56. https://doi.org/10.1016/J.ADDMA.2014.12.007

Jamshidinia M, Kovacevic R (2015) The influence of heat accumulation on the surface roughness in powder-bed additive manufacturing. Surf Topogr Metrol Prop 3:014003. https://doi.org/10.1088/2051-672X/3/1/014003

Thijs L, Verhaeghe F, Craeghs T et al (2010) A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater 58:3303–3312

Promoppatum P, Onler R, Yao S-C (2017) Numerical and experimental investigations of micro and macro characteristics of direct metal laser sintered Ti-6Al-4V products. J Mater Process Technol 240:262–273. https://doi.org/10.1016/J.JMATPROTEC.2016.10.005

Bacchewar PB, Singhal SK, Pandey PM (2007) Statistical modelling and optimization of surface roughness in the selective laser sintering process. Proc Inst Mech Eng Part B J Eng Manuf 221:35–52. https://doi.org/10.1243/09544054JEM670

Qiu C, Panwisawas C, Ward M et al (2015) On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater 96:72–79. https://doi.org/10.1016/J.ACTAMAT.2015.06.004

Zhang B, Li Y, Bai Q (2017) Defect formation mechanisms in selective laser melting: a review. Chin J Mech Eng 30:515–527. https://doi.org/10.1007/s10033-017-0121-5

Shipley H, McDonnell D, Culleton M, Coull R, Lupoi R, O’Donnell G, Trimble D (2018) Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: a review. Int J Mach Tool Manufact 128:1–20. https://doi.org/10.1016/j.ijmachtools.2018.01.003

Sames WJ, List FA, Pannala S et al (2016) The metallurgy and processing science of metal additive manufacturing. Int Mater Rev 61:315–360. https://doi.org/10.1080/09506608.2015.1116649

Fotovvati B, Etesami SA, Asadi E (2019) Process-property-geometry correlations for additively-manufactured Ti–6Al–4V sheets. Mater Sci Eng A 760:431–447. https://doi.org/10.1016/J.MSEA.2019.06.020

Author information

Authors and Affiliations

Contributions

F.A. wrote the manuscript and analyzed the data with significant contributions from E.A. F.A. also conducted all the sample characterizations. B.F. contributed to the writing of the manuscript and analyzing the data. M.F. contributed to the editing of the manuscript, designing the DMLS samples, and preparing the samples. E.A. designed and supervised the research.

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Attarzadeh, F., Fotovvati, B., Fitzmire, M. et al. Surface roughness and densification correlation for direct metal laser sintering. Int J Adv Manuf Technol 107, 2833–2842 (2020). https://doi.org/10.1007/s00170-020-05194-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05194-0