Abstract

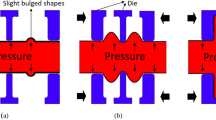

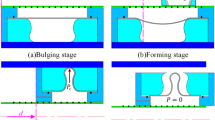

Metal bellows are widely used in piping systems, aerospace, automobile and other industries due to their favourable properties including absorption of expansion, light weight and flexibility. In this paper, the fittability was presented to evaluate the convolution shape precision of the metal bellows. By establishing a finite element model of bellows hydroforming process during the bulging and forming stages, the influence of internal pressure, axial feeding and feeding loading path on the wall thickness variation and fittability of one-convolution bellows was investigated. On that basis, the hydroforming process of multi-convolution bellows was studied, and an experiment was carried out. The results showed that with the increase in internal pressure, the wall thickness of the bellows thinned overall, and the fittability of the root zone of the bellows gradually deteriorated. Some region near the crown zone did not fit the dies well when the internal pressure is small. To improve the fittability of the bellows, the actual axial feeding should be a bit less than the theoretical axial feeding. It is of importance in developing the hydroforming technique and improving the hydroforming quality of bellows.

Similar content being viewed by others

References

Dayyani I, Shaw AD, Flores EIS, Friswell MI (2015) The mechanics of composite corrugated structures: a review with applications in morphing aircraft. Compos Struct 133(1):358–380

Kang BH, Lee MY, Shon SM, Moon YH (2007) Forming various shapes of tubular bellows using a single-step hydroforming process. J Mater Process Technol 194(1–3):1–6

Bakhshi-Jooybari M, Elyasi M, Gorji A (2010) Numerical and experimental investigation of the effect of the pressure path on forming metallic bellows. J Eng Manuf 224(1):95–101

Wei SG, Xu LP, He K, Li JH, Feng W, Du R (2015) Experimental study on manufacturing metal bellows forming by water jet incremental forming. Int J Adv Manuf Technol 81:129–133

Wang G, Zhang KF, Wu DZ, Wang JZ, Yu YD (2006) Superplastic forming of bellows expansion joints made of titanium alloys. J Mater Process Techno 178:24–28

Zhan M, Shi F, Deng Q, Ma F, Chen JH (2014) Mechanism and law of reducing spinning for coreless die for aluminum alloy corrugated pipe. J Plasticity Eng 21(02):108–115 (in Chinese)

Sun L, Lin CY, Fan ZG, Li H, Yao SJ, Wang GD, Chu GC (2019) Experimental and numerical investigation on axial hydro–forging sequence of 6063 aluminum alloy tube. Int J Adv Manuf Technol 105:2869–2877

Abrantes JP, Szabo-Ponce A, Batalha GF (2005) Experimental and numerical simulation of tube hydroforming (THF). J Mater Process Technol 164–165:1140–1147

Liu J, Li HW, Liu Y, Li LY, Sun C (2018) “Size effect” related hydroforming characteristics of thin-walled 316-L bellow considering pressure change. J Mater Process Technol 98(1–4):505–522

Faraji G, Mosavi MM, Norouzifard V (2009) Evaluation of effective parameters in metal bellows forming process. J Mater Process Technol 209(7):3431–3437

Yuan Z, Huo SH, Ren JT, Han JF (2019) Study on the hydroforming technology of reinforced s-shaped bellows. Int J Adv Manuf Technol 103(5–8):2541–2552

Lee SW (2002) Study on the forming parameters of the metal bellows. J Mater Process Technol 130-131(11):47–53

Elyasi M, Bakhshi-Jooybari M, Gorji AH, Nourouzi S, Alinejhad GM (2008) Numerical and experimental investigation on forming metallic bellows in closed and open-die hydroforming. Steel Res Int 79:148–154

Prithvirajan R, Sugavaneswaran M, Sathishkumar N, Arumaikkannu G (2019) Metal bellow hydroforming using additive manufactured die: a case study. Rapid Prototyping J 25(4):765–774

Zheng WT, Su M, Zhou LX (2017) Optimization of hydroforming process for titanium alloy TC4 thin-wall corrugated pipe. J Plastics Eng 24(05):52–58 (in Chinese)

Faraji G, Besharati MK, Mosavi M, Kashanizadeh H (2008) Experimental and finite element analysis of parameters in manufacturing of metal bellows. Int J Adv Manuf Technol 38:641–648

Zhu Y, Wan M, Zhou YK, Liu QH, Li YC, Zheng NS, Pi KS (2012) Hydroforming of complicated thin-walled circular parts with irregular section by using moving dies. Acta Aeronaut Astronau Sin 33(5):912–919 (in Chinese)

Liu J, Wang YL, Li LY, Li X (2017) Influence of process parameters on hydroforming for bi-layered 304 stainless steel bellows. J Plastics Eng 24(4):11–20 (in Chinese)

Hao ZL, Xi CY, Huang ZH, Zhang CH, Luo JT (2018) Hydraulic bulging process with axial feedings and strain field of U-shaped metal bellows. J Cent South Univ 25(11):2712–2721

Zhang KF, Wang G, Wang GF, Wang CW, Wu DZ (2004) The superplastic forming technology of Ti–6Al–4V titanium alloy bellows. Mater Sci Forum 447–448:247–252

Zhang ZC, Furushima T, Manabe K, Tada K, Sasaki O (2015) Development of dieless metal bellows forming process with local heating technique. J Eng Manuf 229(4):664–669

Sedighi M, Shamsi M (2017) A new approach in producing metal bellows by local arc heating: a parametric study. Int J Adv Manuf Technol 93:3211–3219

Chen J (2015) Numerical simulation and process research of high pressure forming in pipe. Shanghai Jiaotong University, Shanghai (in Chinese)

Guo YJ, Wang ZG, Jin GY, Ye SP, Lu ZM, Huang JF, Huang K (2019) Numerical simulation study on the reduction rate of hydroformed bellows. J Zhejiang Univ Technol 47(01):58–62 (in Chinese)

Acknowledgements

The authors would like to thank the Public Welfare Technology Application Research Projects of Zhejiang Province (2016C31043), the Key Research and Development Project of Zhejiang Province (2020C05008), the National Natural Science Foundation of China (51675478 and 51775489), and the Zhejiang University of Technology, Keqiao Innovation Institute Technology Project (2018KQ012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, L., He, Y., Lin, Y. et al. Influence of process parameters on thinning ratio and fittability of bellows hydroforming. Int J Adv Manuf Technol 107, 3371–3387 (2020). https://doi.org/10.1007/s00170-020-05170-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05170-8