Abstract

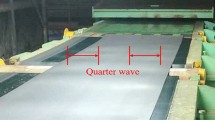

To high-precision control the springback of high-strength steel (HSS) in cold roll forming, the 3D finite element analysis (FEA) models of hat-shaped sectional HSS roll forming process were built with the professional roll forming software COPRA. Two conventional angle adjusting methods for HSS, i.e., the Namaste-type and the Platform-type applied widely for complex-sectional normal steel, easily lead to the edge waves and asymmetric behavior, respectively, especially high springback that is difficult to control by the FEA simulation and practical production of HSS cold roll forming process. The roll design of the UDT (USTB-Durable T)-type angle adjusting method was developed to significantly reduce springback with the improvement of the edge waves and asymmetric behavior in the hat-shaped sectional HSS roll forming process by the FEA simulation. The proposed angle compensation method based on UDT-type angle adjusting method achieved high-precision springback control by the FEA simulation, which provides a novel approach for springback control effectively in complex-sectional HSS roll forming process. The industrial application gives remarkable results that the hat-shaped sectional HSS product can strictly meet market requirements of less than 0.5° by the proposed angle compensation method based on UDT-type angle adjusting method.

Similar content being viewed by others

References

Matlock DK, Speer JG, Moor ED, Gibbs PJ (2012) Recent developments in advanced high strength strip steels for automotive applications. An overview 15:1–12

Cui GJ, Lu XY, Chi ZH (2005) Current situation of the development of roll forming technology. Machinery Manufacturing 43:41–44

Larranaga J, Galdos L, Uncilla L, Etxaleku A (2010) Development and validation of a numerical model for strip metal roll forming. Int J Mater Form 3:151–154

Cho JR, Moon SJ, Moon YH, Kang SS (2003) Finite element investigation on springback characteristics in strip metal U-bending process. J Mater Process Technol 141(1):109–116

Cao JG, Wang L, Liu J, Liu XL, Zhao RG, He ZL (2017) Finite element simulation of roll forming process based on over-bend defect control of shaped tube. J Cent South Univ 48(9):2345–2351

Paralikas J, Salonitis K, Chryssolouris G (2010) Optimization of roll forming process parameters-a semi empirical approach. Int J Adv Manuf Technol 47(9-12SI):1041–1052

Paralikas J, Salonitis K, Chryssolouris G (2011) Investigation of the effect of roll forming pass design on main redundant deformations on profiles from AHSS. Int J Adv Manuf Technol 56(5–8):475–491

Paralikas J, Salonitis K, Chryssolouris G (2009) Investigation of the effects of main roll-forming process parameters on quality for a V-section profile from AHSS. Int J Adv Manuf Technol 44(3–4):223–237

Han F, Wang Y, Wang ZL (2018) Mechanical bending property of ultra-HSS strips in roll forming process. Int J Precis Eng Manuf 19(12):1885–1893

Paralikas J, Salonitis K, Chryssolouris G (2013) Energy efficiency of cold roll forming process. Int J Adv Manuf Technol 66(9–12):1271–1284

Paralikas J, Salonitis K, Chryssolouris G (2013) Robust optimization of the energy efficiency of the cold roll forming process. Int J Adv Manuf Technol 69(1–4):461–481

Liu XL, Cao JG, Chai XT, He ZL, Liu J, Zhao RG (2018) Experimental and numerical prediction of the local thickness reduction defect of complex cross-sectional steel in cold roll forming. Int J Adv Manuf Technol 95(5–8):1837–1848

Yoon JS, Son SE, Song WJ, Kim J, Kang BS (2014) Study on flexibly-reconfigurable roll forming process for multi-curved surface of strip metal. Int J Precis Eng Manuf 15(6):1069–1074

Bidabadi BS, Naeini HM, Tehrani MS, Barghikar H (2015) Experimental and numerical study of bowing defects in cold roll-formed, U-channel sections. J Constr Steel Res 118:243–253

Bidabadi BS, Naeini HM, Tafti RA, Barghikar H (2016) Experimental study of bowing defects in pre-notched channel section products in the cold roll forming process. Int J Adv Manuf Technol 87(1–4):997–1011

Park HS, Anh TV, (2010) Finite element analysis of roll forming process of aluminum automotive component. International Forum on Strategic Technology. IEEE

Abvabi A, Mendiguren J, Kupke A, Rolfe B, Weiss M (2017) Evolution of elastic modulus in roll forming. Int J Mater Form 10(3):463–471

Abeyrathna B, Rolfe B, Hodgson P, Weiss M (2017) Local deformation in roll forming. Int J Adv Manuf Technol 88(9–12):2405–2415

Abeyrathna B, Rolfe B, Weiss M (2017) The effect of process and geometric parameters on longitudinal edge strain and product defects in cold roll forming. Int J Adv Manuf Technol 92(1–4):743–754

Lindgren M (2007) Cold roll forming of a U-channel made of HSS. J Mater Process Technol 186(1–3):77–81

Panthi SK, Ramakrishnan N, Ahmed M, Singh SS, Goel MD (2010) FEA of strip metal bending process to predict the springback. Mater Des 31(2):657–662

Wiebenga JH, Weiss M, Rolfe B, Boogaard AHVD (2013) Product defect compensation by robust optimization of a cold roll forming process. J Mater Process Technol 213(6):978–986

Bui QV, Ponthot JP (2008) Numerical simulation of cold roll-forming processes. J Mater Process Technol 202(1–3):275–282

Abvabi A, Rolfe B, Hodgson PD, Weiss M (2015) The influence of residual stress on a roll forming process. Int J Mech Sci 101-102:124–136

Han F, Mo JH, Qi HW, Long RF, Cui XH (2013) Springback prediction for incremental sheet forming based on FEM-PSONN technology. Trans Nonferrous Metals Soc China 23(4):1061–1071

Groche P, Beiter P, Henkelmann M (2008) Prediction and inline compensation of springback in roll forming of high and ultra-HSSs. Prod Eng 2(4):401–407

Zeng G, Li SH, Yu ZQ, Lai XM (2009) Optimization design of roll profiles for cold roll forming based on response surface method. Mater Des 30(6):1930–1938

Marretta L, Ingarao G, Lorenzo RD (2010) Design of sheet stamping operations to control springback and thinning: a multi-objective stochastic optimization approach. Int J Mech Sci 52(7):914–927

Liang JH, (2014) Optimization of HSS variable cross section roll forming interpolation control strategy, North China University of Technology

Hiroshi O, Liu JY (2007) Cold roll forming. Chemical Industry Press, Beijing

Wang XJ (1994) The production and application of roll formed section steel. Metallurgical Industry Press, Beijing

Hellborg S (2007) Finite element simulation of roll forming. Linköping University, Master Thesis

Nadiah BMSS, Takuo N, Hiroshi O (2014) Effect of initial thickness to cut end deformation of hat shape channel steel by roll forming. Key Eng Mater 622-623:1132–1138

Chen W, Jiang J, Li D, Zou T, Peng Y (2019) Flower pattern and roll positioning design for the cage roll forming process of ERW pipes. J Mater Process Technol 264:295–312

Zeng G, Lai XM, Yu ZQ, Lin ZQ (2009) Numerical simulation and sensitivity analysis of parameters for, multistand roll forming of channel section with outer edge. J Iron Steel Res Int 16(1):32–37

Biswas, A.K., (1967). Ein Beitrag zur Biegung von Blechen zu Rohren und Profilen, Universita¨t Saarbru¨cken

Funding

This study was funded by Innovation Method Fund of China (2016IM010300), Lv yang Jin feng Programme for the Innovation Leading Talents (yzlyjfjh2015CX055), and the Fundamental Research Funds for the Central Universities (FRF-GF-18-010B).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiao-Jiao, C., Jian-Guo, C., Qiu-Fang, Z. et al. A novel approach to springback control of high-strength steel in cold roll forming. Int J Adv Manuf Technol 107, 1793–1804 (2020). https://doi.org/10.1007/s00170-020-05154-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05154-8