Abstract

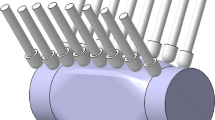

Producing non-uniformly curved tubes with sharp corners using the common experimental methods in hydroforming process is difficult. A common approach is to increase the internal pressure as high as possible; which may lead to excessive thinning and fracture on the corners of the tubes. To manufacture this type of tubes, the current study has proposed a new hydroforming die to perform such a process by taking two general steps: initial bulging and forming. The proposed die facilitated with two movable bushes is able to produce bended stainless steel tubes with non-uniform curvature and cross-section. To find the optimum pressure and axial feed profiles, finite element simulations were performed, and the results were validated with experiments. The main advantage of this die is that by moving the bushes inside the die cavity, the friction between die and bushes can be reduced considerably while axial feeding is provided properly, leading to produce a tube with a uniform thickness distribution and maximum achievable corner filling.

Similar content being viewed by others

References

Ziaeipoor H, Jamshidifard S, Moosavi H, Khademizadeh H (2010) “Numerical analysis of wrinkling phenomenon in hydroforming deep drawing with hemispherical punch”, Proceedings of the 9th WSEAS international conference on system science and simulation in engineering, 96–102

Ziaeipoor H, Ghorbani-Menghari H, Alves De Sousa RJ, Moosavi H, Parastarfeizabadi M, Farzin M, Sanaei H (2014) A novel approach in manufacturing two-stepped tubes using a multi-stage die in tube hydroforming process. Int J Precis Eng Manuf 15(11):1–8. https://doi.org/10.1007/s12541-014-0599-z

Chen FK, Wang SJ, Lin RH (2007) A study of forming pressure in the tube-hydroforming process. J Mater Process Technol 192–193:404–409. https://doi.org/10.1016/j.jmatprotec.2007.04.094

Ahmadi H, Zohoor M (2017) Investigation of the effective parameters in tube hydroforming process by using experimental and finite element method for manufacturing of tee joint products. Int J Adv Manuf Technol 93(1–4):393–405. https://doi.org/10.1007/s00170-016-9690-1

Mao X, Yi Y, Huang S, He H (2018) Bulging limit of AZ31B magnesium alloy tubes in hydroforming with internal and external pressure. Int J Adv Manuf Technol 101(9–12):2509–2517. https://doi.org/10.1007/s00170-018-3076-5

Nikhare C, Weiss M, Hodgson PD (2009) FEA comparison of high and low pressure tube hydroforming of TRIP steel. Comput Mater Sci 47(1):146–152. https://doi.org/10.1016/j.commatsci.2009.06.024

Abdelkefi A, Guermazi N, Boudeau N, Malécot P, Haddar N (2016) Effect of the lubrication between the tube and the die on the corner filling when hydroforming of different cross-sectional shapes. Int J Adv Manuf Technol 87(1–4):1169–1181. https://doi.org/10.1007/s00170-016-8552-1

Xu X, Wu K, Wu Y, Jie X, Fu C (2019) A novel lubrication method for hydroforming of thin-walled aluminum alloy T-shaped tube. Int J Adv Manuf Technol 102(5–8):2265–2273. https://doi.org/10.1007/s00170-019-03339-4

Loh-Mosavi M, Mori K, Hayashi K, Bakhshi-Jooybari M (2007) Improvement of filling of die corners in box-shaped tube hydroforming by control of wrinkling. Key Eng Mater 344:461–467. https://doi.org/10.4028/www.scientific.net/KEM.344.461

Kim SY, Joo BD, Shin S, VanTyne CJ, Moon YH Discrete layer hydroforming of three-layered tubes. Int J Mach Tools Manuf 68:56–62. https://doi.org/10.1016/j.ijmachtools.2013.02.002

Elyasi M, Bakhshi-Jooybari M, Gorji A, Hosseinipour SJ, Nourouzi S (2009) New die design for improvement of die corner filling in hydroforming of cylindrical stepped tubes. J Eng Manuf:821–827. https://doi.org/10.1243/09544054JEM1344

Ghorbani Menghari H, Ziaeipoor H, Farzin M, Alves De Sousa RJ An approach to improve thickness distribution and corner filling of copper tubes during hydro-forming processes. Struct Eng Mech 50(4):563–573. https://doi.org/10.12989/sem.2014.50.4.563,2014

Ziaeipoor H, Taylor M, Pandy M, Martelli S (2019) A novel training-free method for real-time prediction of femoral strain. J Biomech 86:110–116. https://doi.org/10.1016/j.jbiomech.2019.01.057

Kim J, Kang BS, Choi HH, Hwang SM, Kang YH (2002) Comparison of implicit and explicit finite-element methods for the hydroforming process of an automobile lower arm. Int J Adv Manuf Technol 20(6):407–413

Design-Expert software v8 user’s guide (2010) Technical manual. Stat-Ease Inc., Minneapolis

Bahloul R, Arfa H, BelHadjsalah H A study on optimal design of process parameters in single point incremental forming of sheet metal by combining Box–Behnken design of experiments, response surface methods and genetic algorithms. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-014-5975-4,2014

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ghorbani, H., Kim, J.H., Hosseinzadeh, M. et al. Manufacturing of bent tubes with non-uniform curvature and cross-section using a novel hydroforming die: experimental, finite element analysis, and optimization. Int J Adv Manuf Technol 107, 1683–1695 (2020). https://doi.org/10.1007/s00170-020-05133-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05133-z