Abstract

The deformation of aluminum alloy aeronautical plate is a common problem in the processing. The machining deformation can usually be predicted by the initial residual stress in the aluminum alloy plate. In this study, a prediction model considering the extrusion parameters for predicting the machining deformation of aluminum alloy plate is proposed. The FEM simulations and experiments are conducted to validate the accuracy of the prediction model, and not only the residual stress results but also the deformation results show good agreements. In addition, the other four groups of experiments are performed to obtain the results of machining deformation under different extrusion parameters. Finally, the relationship between machining deformation and extrusion parameters is discussed. The extreme values and their positions of the deformations under different parameters are given.

Similar content being viewed by others

References

Chen W, Ni L, Xue J (2008) Deformation control through fixture layout design and clamping force optimization. Int J Adv Manuf Technol 38:860–867. https://doi.org/10.1007/s00170-007-1153-2

Siebenaler SP, Melkote SN (2006) Prediction of workpiece deformation in a fixture system using the finite element method. Int J Mach Tools Manuf 46:51–58. https://doi.org/10.1016/j.ijmachtools.2005.04.007

Santos MCJ, Machado AR, Sales WF, Barrozo MAS, Ezugwu EO (2016) Machining of aluminum alloys: a review. Int J Adv Manuf Technol 86:3067–3080. https://doi.org/10.1007/s00170-016-8431-9

Masoudi S, Amini S, Saeidi E, Eslami-Chalander H (2015) Effect of machining-induced residual stress on the distortion of thin-walled parts. Int J Adv Manuf Technol 76:597–608. https://doi.org/10.1007/s00170-014-6281-x

Li J, Wang S (2017) Distortion caused by residual stresses in machining aeronautical aluminum alloy parts: recent advances. Int J Adv Manuf Technol 89:997–1012. https://doi.org/10.1007/s00170-016-9066-6

Huang X, Sun J, Li J (2015) Finite element simulation and experimental investigation on the residual stress-related monolithic component deformation. Int J Adv Manuf Technol 77:1035–1041. https://doi.org/10.1007/s00170-014-6533-9

Song XM, Wang GZ, Xuan FZ, Tu ST (2015) Investigation of residual stress effects on creep crack initiation and growth using local out-of-plane compression. Eng Fract Mech 149:45–57. https://doi.org/10.1016/j.engfracmech.2015.10.002

Chen LY, Wang GZ, Tan JP, Xuan FZ, Tu ST (2013) Effects of residual stress on creep damage and crack initiation in notched CT specimens of a Cr-Mo-V steel. Eng Fract Mech 97:80–91. https://doi.org/10.1016/j.engfracmech.2012.10.020

Gao H, Zhang Y, Wu Q, Song J (2017) An analytical model for predicting the machining deformation of a plate blank considers biaxial initial residual stresses. Int J Adv Manuf Technol 93:1473–1486. https://doi.org/10.1007/s00170-017-0528-2

Zhang L, Feng X, Li Z, Liu C (2013) FEM simulation and experimental study on the quenching residual stress of aluminum alloy 2024. Proc Inst Mech Eng Part B-J Eng Manuf 227:954–964. https://doi.org/10.1177/0954405412465232

Tanner DA, Robinson JS (2000) Residual stress prediction and determination in 7010 aluminum alloy forgings. Exp Mech 40:75–82. https://doi.org/10.1007/BF02327551

Wei Y, Wang XW (2007) Computer simulation and experimental study of machining deflection due to original residual stress of aerospace thin-walled parts. Int J Adv Manuf Technol 33:260–265. https://doi.org/10.1007/s00170-006-0470-1

Dong H, Ke Y (2006) Study on machining deformation of aircraft monolithic component by FEM and experiment. Chin J Aeronaut 19:247–254. https://doi.org/10.1016/S1000-9361(11)60352-X

Cerutti X, Mocellin K (2015) Parallel finite element tool to predict distortion induced by initial residual stresses during machining of aeronautical parts. Int J Mater Form 8:255–268. https://doi.org/10.1007/s12289-014-1164-0

Liu L, Sun J, Chen W, Sun P (2017) Study on the machining distortion of aluminum alloy parts induced by forging residual stresses. Proc Inst Mech Eng Part B-J Eng Manuf 231:618–627. https://doi.org/10.1177/0954405415583805

Nasr MNA, Ng EG, Elbestawi MA (2008) A modified time-efficient FE approach for predicting machining-induced residual stresses. Finite Elem Anal Des 44:149–161. https://doi.org/10.1016/j.finel.2007.11.005

Fu W, Cohen PH, Ruud CO (2009) Experimental investigation of the machining induced residual stress tensor under mechanical loading. J Manuf Process 11:88–96. https://doi.org/10.1016/j.jmapro.2009.11.001

Oezel T, Zeren E (2007) Finite element modeling the influence of edge roundness on the stress and temperature fields induced by high-speed machining. Int J Adv Manuf Technol 35:255–267. https://doi.org/10.1007/s00170-006-0720-2

Huang X, Sun J, Li J, Han X, Xiong Q (2013) An experimental investigation of residual stresses in high-speed end milling 7050-T7451 aluminum alloy. Adv Mech Eng 2013:592659. https://doi.org/10.1155/2013/592659

Outeiro JC, Umbrello D, M'Saoubi R (2006) Experimental and numerical modelling of the residual stresses induced in orthogonal cutting of AISI 316L steel. Int J Mach Tools Manuf 46:1786–1794. https://doi.org/10.1016/j.ijmachtools.2005.11.013

Gao H, Zhang Y, Wu Q, Li B (2018) Investigation on influences of initial residual stress on thin-walled part machining deformation based on a semi-analytical model. J Mater Process Technol 262:437–448. https://doi.org/10.1016/j.jmatprotec.2018.04.009

Izamshah R, Mo JPT, Ding S (2012) Hybrid deflection prediction on machining thin-wall monolithic aerospace components. Proc Inst Mech Eng Part B-J Eng Manuf 226:592–605. https://doi.org/10.1177/0954405411425443

Jiang Z, Liu Y, Li L, Shao W (2014) A novel prediction model for thin plate deflections considering milling residual stresses. Inter J Adv Manuf Technol 74:37–45. https://doi.org/10.1007/s00170-014-5952-y

Huang X, Sun J, Li J (2015) Effect of initial residual stress and machining-induced residual stress on the deformation of aluminium alloy plate. Strojniski Vestn-J Mech Eng 61:131–137. https://doi.org/10.5545/sv-jme.2014.1897

Yang Y, Li M, Li KR (2014) Comparison and analysis of main effect elements of machining distortion for aluminum alloy and titanium alloy aircraft monolithic component. Int J Adv Manuf Technol 70:1803–1811. https://doi.org/10.1007/s00170-013-5431-x

He N, Wang Z, Jiang C, Zhang B (2003) Finite element method analysis and control stratagem for machining deformation of thin-walled components. J Mater Process Technol 139:332–336. https://doi.org/10.1016/S0924-0136(03)00550-8

Guo H, Zuo DW, Wu HB, Xu F, Tong GQ (2009) Prediction on milling distortion for aero-multi-frame parts. Mater Sci Eng A-Struct Mater Prop Microstruct Process 499:230–233. https://doi.org/10.1016/j.msea.2007.11.137

Tang A, Liu Z (2008) Deformations of thin-walled plate due to static end milling force. J Mater Process Technol 206:345–351. https://doi.org/10.1016/j.jmatprotec.2007.12.089

Zhang Z, Li L, Yang Y, He N, Zhao W (2014) Machining distortion minimization for the manufacturing of aeronautical structure. Int J Adv Manuf Technol 73:1765–1773. https://doi.org/10.1007/s00170-014-5994-1

Tang ZT, Yu T, Xu LQ, Liu ZQ (2013) Machining deformation prediction for frame components considering multifactor coupling effects. Int J Adv Manuf Technol 68:187–196. https://doi.org/10.1007/s00170-012-4718-7

Hirano M, Yamasaki M, Hagihara K, Higashida K, Kawamura Y (2010) Effect of extrusion parameters on mechanical properties of Mg97Zn1Y2 alloys at room and elevated temperatures. Mater Trans 51:1640–1647. https://doi.org/10.2320/matertrans.MAW201026

Ding L, Zhang X, Liu CR (2014) Dislocation density and grain size evolution in the machining of Al6061-T6 alloys. J Manuf Sci Eng-Trans ASME 136:041020. https://doi.org/10.1115/1.4027675

Wu Q, Li D (2014) Analysis and X-ray measurements of cutting residual stresses in 7075 aluminum alloy in high speed machining. Int J Precis Eng Manuf 15:1499–1506. https://doi.org/10.1007/s12541-014-0497-4

Chen Y, Yang Y, Feng Z, Huang B, Luo X (2017) Surface gradient nanostructures in high speed machined 7055 aluminum alloy. J Alloy Compd 726:367–377. https://doi.org/10.1016/j.jallcom.2017.08.018

Wang Z, Yuan J, Yin Z, Hu X (2016) Surface topography and roughness of high-speed milled AlMn1Cu. Chin J Mech Eng 29:1200–1207. https://doi.org/10.3901/CJME.2016.0823.097

Masoudi S, Amirian G, Saeedi E, Ahmadi M (2015) The effect of quench-induced residual stresses on the distortion of machined thin-walled parts. J Mater Eng Perform 24:3933–3941. https://doi.org/10.1007/s11665-015-1695-7

Asano K, Yoneda H, Inui Y (2008) Machinability of short potassium titanate fiber reinforced AC4A aluminum alloy composite. Mater Trans 49:2399–2404. https://doi.org/10.2320/matertrans.MER2008180

Chen S, Zhang Y, Wu Q, Yan D (2019) Residual stress relief for 2219 aluminum alloy weldments: a comparative study on three stress relief methods. Metals 9:419. https://doi.org/10.3390/met9040419

Wu Q, Wu J, Zhang Y, Gao H, Hui D (2019) Analysis and homogenization of residual stress in aerospace ring rolling process of 2219 aluminum alloy using thermal stress relief method. Int J Mech Sci 157-158:111–118. https://doi.org/10.1016/j.ijmecsci.2019.04.040

Singh A, Agrawal A (2015) Investigation of surface residual stress distribution in deformation machining process for aluminum alloy. J Mater Process Technol 225:195–202. https://doi.org/10.1016/j.jmatprotec.2015.05.025

Wu Q, Li D, Zhang Y (2016) Detecting milling deformation in 7075 aluminum alloy aeronautical monolithic components using the quasi-symmetric machining method. Metals 6:80. https://doi.org/10.3390/met6040080

Saleem W, Ijaz H, Zain-ul-Abdein M, Taimoor AA, Wang Y (2017) Studying control strategies for dimensional precision in aerospace parts machining. Int J Precis Eng Manuf 18:39–47. https://doi.org/10.1007/s12541-017-0005-8

Xie JX, Liu JA (2012) Theory and technology of metals extrusion. Metallurgical Industry Press, Beijing, China (in Chinese)

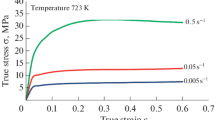

Xie ZD, Guan YJ, Lin J, Zhai JQ, Zhu LH (2019) Constitutive model of 6063 aluminum alloy under the ultrasonic vibration upsetting based on Johnson-Cook model. Ultrasonics 96:1–9. https://doi.org/10.1016/j.ultras.2019.03.017

Funding

This work was supported by the National Natural Science Foundation of China (number 51875024), the Defense Industrial Technology Development Program (number JCKY2018601C002), the Civil Aerospace Technology Pre-research Project (number B0109), and the State Key Laboratory of Virtual Reality Technology Independent Subject (number BUAA-VR-16ZZ-07).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, Q., Xue, NP., Zhang, YD. et al. A prediction model of the extrusion deformation with residual stress on 6063 aluminum alloy aeronautical plate considering different extrusion parameters. Int J Adv Manuf Technol 107, 1671–1681 (2020). https://doi.org/10.1007/s00170-020-05102-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05102-6