Abstract

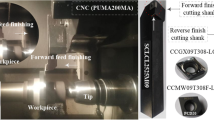

The machined surface integrity has significance on fatigue life. The step-by-step feed cutting is put forward and adopted to machine ZL109 aluminum-silicon piston alloy. In addition, the forward and reverse finish cutting is also proposed to improve the machined quality and fatigue life. The result indicates that the step-by-step feed cutting can effectively avoid scratching and decrease surface roughness, bring about the compressive residual stress, and improve machined quality. Moreover, there is smaller elastic-plastic recovery and thermal expansion on the machined surface, when the step-by-step feed cutting is adopted, so that the machining dimension accuracy can be ensured perfectly. The forward and reverse finish cutting can effectively decrease the surface roughness and the tensile residual stress due to the thermal stress. So the larger the cutting thickness is, the smaller surface residual stress is, when the cutting depth is 0.15–0.30 mm in the forward and reverse finish cutting. It can improve the machined quality of ZL109 aluminum-silicon piston alloy and the fatigue life when the reasonable cutting parameter is adopted. Those results have an important practical significance.

Similar content being viewed by others

References

Wang JF, Xie JP, Liu ZX, Li JW, Weng YG, Wang MX (2005) Review on the research and application of Al-Si piston alloy at home and abroad. Foundry 54(1):24–27

Konečná R, Nicoletto G, Kunz L, Svoboda M, Bača A (2014) Fatigue strength degradation of AlSi12CuNiMg alloy due to high temperature exposure: a structural investigation. Procedia Eng 74:43–46

Joyce MR, Styles CM, Reed PAS (2003) Elevated temperature short crack fatigue behaviour in near eutectic Al–Si alloys. Int J Fatigue 25(9):863–869

Zeren M (2007) The effect of heat-treatment on aluminum-based piston alloys. Mater Des 28:2511–2517

El-Axir MH (2002) A method of modeling residual stress distribution in turning for different materials. Int J Mach Tool Manu 42(9):1055–1063

Papahn H, Bahemmat P, Valipour A (2014) Ultrasonic measurements of residual stresses caused by severe thermomechanical deformation during FSW. Exp Mech 54(9):1587–1596

Wang SY, Ai X, Zhao J, Li ZL, Meng H (2005) Effect of cutting speed on residual stress of workpiece by using FEM. Tool Eng 39(9):33–36

El-Helieby SOA, Rowe GW (1980) A quantitative comparison between residual stresses and fatigue properties of surface-ground bearing steel (En 31). Wear 58(1):155–172

Jeelani S, Musial M (1986) Dependence of fatigue life on the surface integrity in the machining of 2024-T351 aluminium alloy — unlubricated conditions. J Mater Sci 21(1):155–160

James MN, Hughes DJ, Chen Z, Lombard H, Hattingh DG, Asquith D, Yates JR, Webster PJ (2007) Residual stresses and fatigue performance. Eng Fail Anal 14(2):384–395

Zou X, Liang YL, Wu ZL, Qin SJ, Hu JJ (2017) Effects of abrasive waterjet peening on surface integrity and fatigue properties of carburizing GDL-1 steel. China Surf Eng (2):47-53

Arola D, Williams CL (2002) Estimating the fatigue stress concentration factor of machined surfaces. Int J Fatigue 24(9):923–930

Novovic D, Dewes RC, Aspinwall DK, Voice W, Bowen P (2004) The effect of machined topography and integrity on fatigue life. Int J Mach Tool Manu 44(2–3):125–134

Ardi DT, Li YG, Chan KHK, Blunt L, Bache MR (2014) The effects of machined topography on fatigue life of a nickel based superalloy. Procedia CIRP 13:19–24

Andrews S, Sehitoglu H (2015) A computer model for fatigue crack growth from rough surfaces. Int J Fatigue 22(7):619–630

Suraratchai M, Limido J, Chieragatti R (2008) Modelling the influence of machined surface roughness on the fatigue life of aluminium alloy. Int J Fatigue 30(12):2119–2126

Xu XC, Liu DX, Zhang XH, Liu CS, Liu D, Zhang WC (2019) Influence of ultrasonic rolling on surface integrity and corrosion fatigue behavior of 7B50-T7751 aluminum alloy. Int J Fatigue 125:237–248

Li XH, Li WH, Wang CW, Yang SQ, Shi HT (2018) Surface integrity and anti-fatigue performance of TC4 titanium alloy by mass finishing. China Surf Eng 31(1):15–25

Wu DX, Zhang DH, Yao CF (2017) Effect of surface integrity of turned GH4169 superalloy on fatigue performance. J Aeronaut Mater 37(6):59-67

Li SP, Liu DX, Li RH, Xia ML, Zhang W, Mj Q, Du DX (2012) Influence of shot peening and surface integrity on fatigue properties of TC21 titanium alloy. Mech Sci Technol Aerospace Eng 31(12):1418–1423

Javidi A, Rieger U, Eichlseder W (2008) The effect of machining on the surface integrity and fatigue life. Int J Fatigue 30(10–11):2050–2055

Yao CF, Tan L, Ren JX, Lin Q, Liang YS (2014) Surface integrity and fatigue behavior for high-speed milling Ti–10V–2Fe–3Al titanium alloy. J Fail Anal Prev 14(1):102-112

Prema S, Shreeshail GY, Chandrashekharaiah TM (2015) Analysis of machining parameter and surface finish of Al-Si alloys with grain refiners and/or modifier. Mater Sci Forum 830-831:91–94

Sun H, Li A, Zhou Y, Liao XL, Ge DJ (2019) Dry wear characteristics of machined ZL109 aluminum-silicon alloy surface under unidirectional and reciprocating rolling-contact friction. Surf Topogr Metrol Prop 8(1): 015001

Shao F, Liu ZQ, Wan Y, Zhang BG (2010) Diffusion wear for PCD tools cutting aluminum alloy ZL109 based on thermodynamics. J Tianjin Univ 43(4):315-321

Wang B, Liu ZQ (2016) Effect of material dynamic properties on the chip formation mechanism during high speed machining. Scientia Sinica Technol 46(1):1–19

Masuko M, Kumabe J (1959) A few new methods of metal cutting to get a fine surface at low speed: sub-zero-, reversal finish-, and ultrasonic cutting. Bulletin JSME 2(7):487–494

Yang NX, Qi XY, Chen BJ, Xu H (1991) A study of adjusting residual stresses in machined surface by reversal finish cutting. J South China Univ Technol (Nat Sci Ed) 19(2):15-21

Sun H, Li AH, Zhou YH, Hou GM (2019) Study of surface quality in turning of aluminum-silicon alloy ZL109. Tool Engineering 53(04):8–13

Lin C, Wu SS, Lü SL, An P, Wan L (2013) Effects of ultrasonic vibration and manganese on microstructure and mechanical properties of hypereutectic Al–Si alloys with 2%Fe. Intermetallics 32:176–183

Fu XL (2007) Constitutive equation for 7050 aluminum alloy at high temperatures. M.S. Dissertation, Shandong University, China

Hill SI, Kuhlman SH, Wang K, Belwafa J, Chen X (2009) Bake-hardening effect of dual phase steels. SAE Technical Paper 2009-01-0796

Li AH, Zhao J, Luo HB, Pei ZQ, Wang ZM (2012) Progressive tool failure in high-speed dry milling of Ti-6Al-4V alloy with coated carbide tools. Int J Adv Manuf Technol 58(5–8):465–478

Huang W, Zhao J, Ai X, Wang GJ, Tao HW (2018) Influence of tool path strategies on fatigue performance of high-speed ball-end-milled AISI H13 steel. Int J Adv Manuf Technol 94(1–4):371–380

Neuber H (1958) Theory of notch stress, vol 204. Springerver-lag, Berlin

Wang ZQ, Liu CF (2015) Literature review of residual stress on the surface in the cutting. Aeronaut Manuf Technol 06:28–32

Niu JT, Liu ZQ, Ai X, Wang GJ, Duan R (2019) Characteristics of machined surface integrity in face milling Al-Li alloy 2A97 with carbide inserts. Int J Adv Manuf Technol 101(1–4):839–848

Wang GJ, Liu ZQ, Ai X, Huang WM, Niu JT (2018) Effect of cutting parameters on strain hardening of nickel–titanium shape memory alloy. Smart Mater Struct 27(7):075027

Ai X (2003) High speed machining technology. National Defense Industry Press, Beijing

Xing DL, Zhang JH, Shen XH, Zhao YF (2011) Experimental study on surface roughness of aluminum alloy in micro-milling process. Manuf Technol Mach Tool 03:36–39

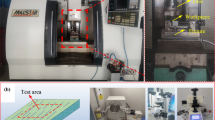

Zhou YH, Sun H, Li AH, Lv MH, Xue CY, Zhao J (2019) FEM simulation-based cutting parameters optimization in machining aluminum-silicon piston alloy ZL109 with PCD tool. J Mech Sci Technol 33:3457–3465

Kuznetsov VP, Dmitriev AI, Anisimova GS, Semenova YV (2016) Optimization of nanostructuring burnishing technological parameters by Taguchi method. IOP Conf Ser Mater Sci Eng 124(1):012022

Damon J, Dietrich S, Vollert F, Gibmeier J, Schulze V (2018) Process dependent porosity and the influence of shot peening on porosity morphology regarding selective laser melted AlSi10Mg parts. Addit Manuf 20:77–89

Zhou Z, Guo D (1987) Pre-stressed machining. Proceedings of the 9th ICPR 1: 257-263

Funding

This work was supported by the National Natural Science Foundation of China (51605260), the Key Research and Development Program of Shandong Province - Public Welfare Special (2017GGX30144, 2018GGX103043), and the Young Scholars Program of Shandong University (2018WLJH57).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sun, H., Li, A., Zhou, Y. et al. Surface integrity enhancement of ZL109 aluminum-silicon piston alloy employing the forward and reverse finish cutting method. Int J Adv Manuf Technol 107, 617–629 (2020). https://doi.org/10.1007/s00170-020-05039-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05039-w