Abstract

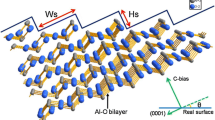

Recently, sapphire has been used in a wide range of applications including optics, consumer electronics, and especially the rapidly growing LED wafer manufacturing. This paper investigates effects of a novel compound slurry composed of micron scaled diamond abrasives and various nano-platelets of graphene oxide (GO) for improving lapping performance of c-plane single-crystal aluminum oxide (Al2O3) sapphire wafers. Four kinds of graphenes including GO, reduced graphene oxide (RGO), ML-RGO (laminate), and MF-RGO (few-layer) are added into the diamond slurry to achieve compound slurries. Those compound slurries have been prepared with various graphene weight fractions in the range of 0.3 to 2.0 wt%, by LP (low power) or HP (high power) ultrasonication with different time spans in the range of 10 min to 48 h to adjust size of GOs. For the lapping process conducted by 10-min HP ultrasonicated GO (2.0 wt%)/diamond slurry, combination of medium down force pressure and the highest platen rotation speed of 45 kPa/80 rpm results in highest material removal rate (MRR) of 926.73 nm/min, which is 324% higher than MRR by pure diamond slurry. It is caused by high reactivity of GOs with sapphire wafer. As lapped at pressure/speed of 45 kPa/70 rpm by ultrasonicated GO (0.5 wt%)/diamond compound slurry, the average surface roughness Ra of wafer can reach 7.19 nm, which is 0.7% lower than 7.24 nm by pure diamond slurry. Experimental results demonstrate that the optimized planarization of sapphire wafer with high MRR and low surface roughness can be achieved using the GO compound slurry when the mechanical removal effect and the chemical reaction mechanism are in synergistic equilibrium. The XPS and EDS analyses clearly support the material removal model that a reactant aluminum carbonate layer and a residual carbon layer exist and both are efficiently removed by diamond abrasives. Results of this study can be applied to further explore high volume production of CMP of sapphire wafers.

Similar content being viewed by others

References

Xu Y, Lu J, Xu X, Chen CCA, Lin Y (2018) Study on high efficient sapphire wafer processing by coupling SG-mechanical polishing and GLA-CMP. Int J Mach Tools Manuf 130-131:12–19

Uhlmann E, List M, Patraschkov M, Trachta G (2018) A new process design for manufacturing sapphire wafers. Precis Eng 53:146–150

Wu K, Zhou L, Shimizu J, Onuki T, Yamamoto T, Ojima H, Yuan J (2017) Study on the potential of chemo-mechanical-grinding (CMG) process of sapphire wafer. Int J Adv Manuf Technol 91:1539–1546

Lin ZC, Wang RY (2014) Abrasive removal depth for polishing a sapphire wafer by a cross-patterned polishing pad with different abrasive particle sizes. Int J Adv Manuf Technol 74:25–36

Chen CCA, Shu LS, Lee SR (2003) Mechano-chemical polishing of silicon wafers. J Mater Process Technol 140:373–378

Chen CCA, Hsu LS (2008) A process model of wafer thinning by diamond grinding. J Mater Process Technol 201:606–611

Wen D, Wang Z, Zhang K (2009) Experimental investigation on the effect of abrasive grain size on the lapping uniformity of sapphire wafer. Proceedings of SPIE, 7282, May 20, 72820C

Xu Y, Lu J, Xu X (2016) Study on planarization machining of sapphire wafer with soft-hard mixed abrasive through mechanical chemical polishing. Appl Surf Sci 389:713–720

Zhou Y, Pan G, Gong H, Shi X, Zou C (2017) Characterization of sapphire chemical mechanical polishing performances using silica with different sizes and their removal mechanisms. Colloids and Surfaces A: Physicochem Eng Aspects 513:153–159

Lei H, Tong K, Wang Z (2016) Preparation of Ce-doped colloidal SiO2 composite abrasives and their chemical mechanical polishing behavior on sapphire substrates. Mater Chem Phys 172:26–31

Li C, Adamcik J, Mezzenga R (2012) Biodegradable nanocomposites of amyloid fibrils and graphene with shape-memory and enzyme-sensing properties. Nat Nanotechnol 7:421–427

Compton OC, An Z, Putz KW, Hong BJ, Hauser BG, Brinson LC, Nguyen ST (2012) Additive-free hydrogelation of graphene oxide by ultrasonication. Carbon 50:3399–3406

Li D, Muller MB, Gilje S, Kaner RB, Wallace GG (2008) Processable aqueous dispersions of graphene nanoplatelets. Nat Nanotechnol 3:101–105

Hummers WS, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80:1339–1339

Dreyer DR, Park S, Bielawski CW, Ruoff RS (2010) The chemistry of graphene oxide. Chem Soc Rev 39:228–240

Pei S, Cheng HM (2012) The reduction of graphene oxide. Carbon 50:3210–3228

Mao S, Pu H, Chen J (2012) Graphene oxide and its reduction: modeling and experimental progress. RSC Adv 2:2643–2662

Takaya Y, Tachika H, Hayashi T, Kokubo K, Suzuki K (2009) Performance of water-soluble fullerenol as novel functional molecular abrasive grain for polishing nanosurfaces. CIRP Annals-Manufacturing Technology 58:495–498

Tsai MY, Yan LW (2010) Characteristics of chemical mechanical polishing using graphite impregnated pad. Int J Mach Tools Manuf 50:1031–1037

Kishida H, Hayashi T, Takaya Y, Kokubo K, Suzuki K (2009) Effect of fullerene poly-hydroxide on cu-CMP process. Proceedings of 5th International Conference on Leading Edge Manufacturing in 21st Century: LEM21, Osaka, Japan, paper C11

Liu HK, Wang YC, Huang TH (2016) Moisture effect on mechanical properties of graphene/epoxy nanocomposites. J Mech 32:673–682

Fu WE, Lin TY, Chen MK, Chen CCA (2009) Surface qualities after chemical–mechanical polishing on thin films. Thin Solid Films 517:4909–4915

Liu HK, Chen CCA, Chen CJ (2019) Effect of graphene additions on polishing of silicon carbide wafer with functional PU/silica particles in CMP slurry. Funct Mater Lett 12:1950066

Moulder JH (1992) Handbook of X-ray photoelectron spectroscopy. Perkin-Elmer Corporation, Minnesota, Physical Electronics Division, pp 41–54

Maruyama B, Ohuchi FS, Rabenberg L (1990) Catalytic carbide formation at aluminum-carbon interfaces. J Mater Sci Lett 9:864–866

Acknowledgments

The authors are grateful for the financial support from Ministry of Science and Technology in Taiwan on this work under contract MOST 104-2221-E-035-084.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, HK., Chen, CC.A. & Chen, WC. Effects of compound diamond slurry with graphene for lapping of sapphire wafers. Int J Adv Manuf Technol 106, 4755–4768 (2020). https://doi.org/10.1007/s00170-020-04951-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-04951-5