Abstract

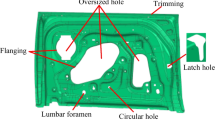

Trimming inserts with complicated geometric features are widely used in the manufacture of automotive panels. The number of trimming inserts for a typical automotive panel is usually more than 20, even up to 100. The design of trimming inserts is a complex and time-consuming process, which significantly affects the development period and quality of automotive panels. However, the design of trimming insert needs to handle a lot of complex geometrical problems, such as 3D curve offset problems. The current commercial CAD software cannot provide a complete and effective solution to the problem, where a lot of tedious human-intersections are needed. This paper presents a systematic methodology which includes the automation of trimming lines division and trimming inserts design. An automatic-decomposition algorithm is presented to divide the trimming lines into short segments. Then the trimming insert is designed for each divided trimming segment. In order to automate the design of trimming insert, a bulking-fairing algorithm is introduced to fair planar curves to meet physical constraints, and a robust 3D curve offset method is proposed to generating 3D offset curves to overcome the main limitation of existing methods. Lastly, the path-interference-check algorithm is presented to check if the interference occurs during the trimming process. This system is implemented and has applications in industry. Case studies and industrial applications have demonstrated the system’s powerful ability in design trimming inserts of automotive panel, and the efficiency for insert design could be improved by 80% at least.

Similar content being viewed by others

References

Li G, Yang P, Liang Z, Cui S (2019) Intelligent design and group assembly of male and female dies for hole piercing of automotive stamping dies. Int J Adv Manuf Technol 103(1):665–687. https://doi.org/10.1007/s00170-019-03576-7

Qattawi A, Mayyas A, Dongri S, Omar M (2014) Knowledge-based systems in sheet metal stamping: a survey. Int J Comput Integr Manuf 27(8):707–718. https://doi.org/10.1080/0951192X.2013.834463

Golovashchenko SF (2008) Quality of trimming and its effect on stretch flanging of automotive panels. J Mater Eng Perform 17(3):316–325. https://doi.org/10.1007/s11665-008-9220-x

Du T, Zhang ZB, Liu YQ (2011) Fast estimation of complex 3D trimming line and evaluation of flanging formability for automobile covering panel. Mater Res Innov 15(sup1):319–323. https://doi.org/10.1179/143307511X12858957674436

Jiang K, Zhou X, Li M (2013) Computer-aided checking fixture design system for automobile parts. Int J Prod Res 51(20):6045–6069. https://doi.org/10.1080/00207543.2013.793421

Shin H, Cho SK (2002) Directional offset of a 3D curve. Proceedings of the Seventh ACM symposium on Solid modeling and applications. https://doi.org/10.1145/566282.566329

Lin B-T, Chan C-K, Wang J-C (2008) A knowledge-based parametric design system for drawing dies. Int J Adv Manuf Technol 36(7):671–680. https://doi.org/10.1007/s00170-006-0882-y

Lin B-T, Chang M-R, Huang H-L, Liu C-Y (2008) Computer-aided structural design of drawing dies for stamping processes based on functional features. Int J Adv Manuf Technol 42(11):1140. https://doi.org/10.1007/s00170-008-1670-7

Lin B-T, Kuo C-C (2008) Application of an integrated CAD/CAE/CAM system for stamping dies for automobiles. Int J Adv Manuf Technol 35(9):1000–1013. https://doi.org/10.1007/s00170-006-0785-y

Wei Y, Wang Z, Zhang Z, Liu Y (2017) Robust methodology of automatic design for automobile panel drawing die based on multilevel modeling strategy. Int J Adv Manuf Technol 91(9):4203–4217. https://doi.org/10.1007/s00170-017-0082-y

Li G, Long X, Zhou M, Xiong H, Wang W (2017) A geometric feature-based design system of full parametric association modeling of standard cam for automotive stamping dies. Int J Adv Manuf Technol 92(9):3627–3645. https://doi.org/10.1007/s00170-017-0421-z

Zheng J, Wang Y, Li Z (2007) KBE-based stamping process paths generated for automobile panels. Int J Adv Manuf Technol 31(7):663–672. https://doi.org/10.1007/s00170-005-0239-y

Tsai Y-L, You C-F, Lin J-Y, Liu K-Y (2010) Knowledge-based engineering for process planning and die design for automotive panels. Comput-Aided Des Appl 7(1):75–87. https://doi.org/10.3722/cadaps.2010.75-87

You C-F, Yang Y-H, Wang D-K (2011) Knowledge-based engineering supporting die face design of automotive panels. In: Industrial design—new frontiers. Intech, Rijeka, pp 21–38

Li G, Zhou M, Wang W, Xiong H, Chen Z (2018) Accurate trimming line optimization of multi-station progressive die for complex automotive structural parts. Int J Adv Manuf Technol 95(1):1185–1203. https://doi.org/10.1007/s00170-017-1258-1

Wang YL, Wang GY (2014) Study on modular design of trimming die structure for automotive panels. Adv Mater Res. https://doi.org/10.4028/www.scientific.net/AMR.945-949.73

Hao Y, Wang Y (2016) A knowledge-based parametric design system for trimming dies. DEStech Transactions on Computer Science and Engineering. https://doi.org/10.12783/dtcse/icmsie2016/6315

Piegl LA, Tiller W (1999) Computing offsets of NURBS curves and surfaces. Comput Aided Des 31(2):147–156

Lee J, Kim Y-J, Kim M-S, Elber G (2015) Efficient offset trimming for deformable planar curves using a dynamic hierarchy of bounding circular arcs. Comput Aided Des 58:248–255. https://doi.org/10.1016/j.cad.2014.08.031

Lin H, Zhang Z (2011) An extended iterative format for the progressive-iteration approximation. Comput Graph 35(5):967–975. https://doi.org/10.1016/j.cag.2011.07.003

Ray BK, Pandyan R (2003) ACORD—an adaptive corner detector for planar curves. Pattern Recogn 36(3):703–708. https://doi.org/10.1016/S0031-3203(02)00084-5

Piegl L, Tiller W (1997) The NURBS book, 2nd edn. Springer, New York

Elber G, Cohen E (1991) Error bounded variable distance offset operator for free form curves and surfaces. Int J Comput Geom Appl 01(01):67–78. https://doi.org/10.1142/s0218195991000062

Ahn YJ, Hoffmann C, Kim YS (2011) Curvature continuous offset approximation based on circle approximation using quadratic Bézier biarcs. Comput Aided Des 43(8):1011–1017. https://doi.org/10.1016/j.cad.2011.04.005

Khan MA, Chen ZC (2012) Approximation of planar offset curves with globally bounded error for B-spline NC tool paths. Int J Prod Res 50(23):6811–6825. https://doi.org/10.1080/00207543.2011.626804

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, J., Kong, C. & Zhou, X.H. Automatic design for trimming die insert of automotive panel. Int J Adv Manuf Technol 106, 4451–4465 (2020). https://doi.org/10.1007/s00170-020-04938-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-04938-2