Abstract

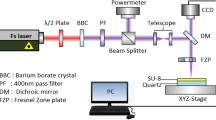

An elliptical zone plate (EZP) is used to replace a Fresnel zone plate to focus a light beam when the optical axes of the incident and diffracted beams are not in a straight line. There are two advantages of using an EZP which contributes to improving the performance. First, the residual beam is not focused to the same direction of the main source. Second, the light returning from the focal plane is not directed to the light beam source. In this paper, we propose a method to fabricate an EZP with a direct laser lithographic system. In this paper, three types of writing (lithographic) paths were investigated to study the cause of the appearance of the ablation phenomenon and the side-wing effect. Then, we suggest a suitable fabricated motion to produce a fine EZP. In addition, an experiment setup for an optical evaluation system was introduced to verify the performance of the EZP array fabricated by the selected method.

Similar content being viewed by others

References

Deng H, Chen C, He MY, Li JJ, Zhang HL, Wang QH (2019) High-resolution augmented reality 3D display with use of a lenticular lens array holographic optical element. J Opt Soc Am A 36(4):588–593

Goncharsky A, Goncharsky A, Durlevich S (2016) Diffractive optical element for creating visual 3D images. Opt Express 24(9):9140–9148

Golub MA, Grossinger I (2005) Diffractive optical elements for biomedical applications. In: Biomedical Systems and Technologies II, pp 220–231

Rhee HG, Lee YW (2010) Improvement of linewidth in laser beam lithographed computer generated hologram. Opt Express 18(2):1734–1740

Poleshchuk AG et al (1999) Polar coordinate laser pattern generator for fabrication of diffractive optical elements with arbitrary structure. Appl Opt 38(8):1295–1301

Kumar K, Cao H, Zhang X (2008) Monolithic integration of binary-phase Fresnel zone plate objectives on 2-axis scanning micromirrors for compact microendoscopes. In: Technical Digest - Solid-State Sensors, Actuators, and Microsystems Workshop, pp 292–295

Leon G, Herran LF, Munoz M, Las-Heras F, Hao Y (2014) Millimeter-wave offset Fresnel zone plate lenses characterization. Prog Electromagn Res C 54:125–131

Guo YJ, Barton SK (1994) Offset Fresnel zone plate antennas. Int J Satell Commun 12(4):381–385

van Houten JM (2005) The elliptical Fresnel-zone plate antenna. In: Ninth International Conference on Antennas and Propagation (ICAP), p v1–97-v1–97

Ade H, Ko CH, Anderson E (1992) Astigmatism correction in x-ray scanning photoemission microscope with use of elliptical zone plate. Appl Phys Lett 60(9):1040–1042

Lebugle M, Liebi M, Wakonig K, Guzenko VA, Holler M, Menzel A, Guizar-Sicairos M, Diaz A, David C (2017) High-acceptance versatile microfocus module based on elliptical Fresnel zone plates for small-angle X-ray scattering. Opt Express 25(18):21145–21158

Kamiya T, Tsuchiya M (2005) Progress in ultrafast photonics. Jpn J Appl Phys Part 1 44(8):5875–5888

Ko FJ, Shieh HPD (2005) Asymmetrical microlens array light control film for reflective LCDs application. Symp Dig Techn Pap 31(1):1071–1073

Kim YG, Rhee HG, Ghim YS, Lee YW (2019) Method of fabricating an array of diffractive optical elements by using a direct laser lithography. Int J Adv Manuf Technol 101(5–8):1681–1685

Cohen DK, Gee WH, Ludeke M, Lewkowicz J (1984) Automatic focus control: the astigmatic lens approach. Appl Opt 23(4):565–570

Rhee HG, Kim DI, Lee YW (2009) Realization and performance evaluation of high speed autofocusing for direct laser lithography. Rev Sci Instrum 80(7):073103/1–073103/5

Kim YG, Rhee HG, Ghim YS, Yang HS, Lee YW (2017) Dual-line fabrication method in direct laser lithography to reduce the manufacturing time of diffractive optics elements. Opt Express 25(3):1636–1645

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Anh, N.N.H., Kim, YG., Rhee, HG. et al. Novel fabrication process for an array of elliptical zone plates by using direct laser lithography. Int J Adv Manuf Technol 106, 2629–2634 (2020). https://doi.org/10.1007/s00170-019-04818-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04818-4