Abstract

This paper discusses the correlations between the electromechanical impedance (EMI) technique and grinding parameters. The EMI technique applied in grinding is novel and has the advantage of employing cheaper equipment and requiring a simpler monitoring system when compared to traditional techniques, such as acoustic emission. Experimental tests were conducted in a controlled environment to isolate the variables of interest, and real and imaginary parts of the impedance were investigated for several frequency bands. Strong correlations among EMI and equivalent chip thickness, roughness, and microhardness of the workpiece, as well as power signals, were found. The RMSD (root-mean-square deviation) index for the real part of the signature in the band 80–85 kHz showed good correlation with roughness and power, while the CCDM (correlation coefficient deviation metric) index for the imaginary part of 50–55 kHz showed good correlation with microhardness. Those correlations allow the user to infer information about the grinding process through indirect monitoring.

Similar content being viewed by others

Abbreviations

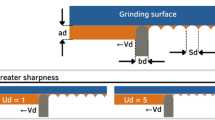

- (ae):

-

Depth of cut, μm

- CCDM:

-

Correlation coefficient deviation metric

- h eq :

-

Equivalent chip thickness, μm

- Q’ w :

-

Specific material removal rate, mm3/mm.s

- ρ :

-

Pearson correlation coefficient

- R a :

-

Arithmetic average roughness, μm

- RMSD :

-

Root-mean-square deviation

- vs :

-

Cutting speed, m/s

- v w :

-

Workpiece speed, m/min

- Z 1 :

-

Impedance of the health structure, Ohm

- Z 2 :

-

Impedance of the damaged structure, Ohm

- Z E :

-

Electrical impedance, Ohm

- Z S :

-

Mechanical impedance of the structure, Ohm

- Z T :

-

Impedance of the piezoelectric, Ohm

References

Klaic M, Murat Z, Staroveski T, Brezak D (2018) Tool wear monitoring in rock drilling applications using vibration signals. Wear 408–409:222–227. https://doi.org/10.1016/j.wear.2018.05.012

Uekita M, Takaya Y (2017) Tool condition monitoring technique for deep-hole drilling of large components based on chatter identification in time – frequency domain. Measurement 103:199–207. https://doi.org/10.1016/j.measurement.2017.02.035

Alexandre FA, Lopes WN, Dotto FRL et al (2018) Tool condition monitoring of aluminum oxide grinding wheel using AE and fuzzy model. Int J Adv Manuf Technol 1:1–13. https://doi.org/10.1007/s00170-018-1582-0

Ferreira FI, de Aguiar PR, Lopes WN et al (2019) Inferential measurement of the dresser width for the grinding process automation. Int J Adv Manuf Technol 100:3055–3066. https://doi.org/10.1007/s00170-018-2869-x

Drouillet C, Karandikar J, Nath C et al (2016) Tool life predictions in milling using spindle power with the neural network technique. J Manuf Process 22:161–168. https://doi.org/10.1016/j.jmapro.2016.03.010

Wegener K, Hoffmeister HW, Karpuschewski B et al (2011) Conditioning and monitoring of grinding wheels. CIRP Ann - Manuf Technol 60:757–777. https://doi.org/10.1016/j.cirp.2011.05.003

Tanaka K, Koshy P (2018) A pneumatic sensor for grinding wheel condition monitoring. Precis Eng. https://doi.org/10.1016/j.precisioneng.2018.09.005

Bhuiyan MSH, Choudhury IA, Dahari M et al (2016) Application of acoustic emission sensor to investigate the frequency of tool wear and plastic deformation in tool condition monitoring. Measurement 92:208–217. https://doi.org/10.1016/j.measurement.2016.06.006

Arun A, Rameshkumar K, Unnikrishnan D, Sumesh A (2018) Tool condition monitoring of cylindrical grinding process using acoustic emission sensor. Mater Today Proc 5:11888–11899. https://doi.org/10.1016/j.matpr.2018.02.162

Miranda HI, Oliveira JRP, Martins C et al (2015) Monitoring single-point dressers using fuzzy models. In: 9th CIRP conference on intelligent computation in manufacturing engineering. Elsevier B.V., pp 281–286

D’Addona DM, Matarazzo D, de Aguiar PR et al (2016) Neural networks tool condition monitoring in single-point dressing operations. Procedia CIRP 41:431–436. https://doi.org/10.1016/j.procir.2016.01.001

Martins CHR, Aguiar PR, Frech A, Bianchi EC (2014) Tool condition monitoring of single-point dresser using acoustic emission and neural networks models. IEEE Trans Instrum Meas 63:667–679. https://doi.org/10.1109/TIM.2013.2281576

Moia DFG, Thomazella IH, Aguiar PR, Bianchi EC, Martins CHR, Marchi M (2014) Tool condition monitoring of aluminum oxide grinding wheel in dressing operation using acoustic emission and neural networks. J Braz Soc Mech Sci Eng 37:627–640. https://doi.org/10.1007/s40430-014-0191-6

da Conceição Junior PO, Ferreira FI, de Aguiar PR et al (2018) Time-domain analysis based on the electromechanical impedance method for monitoring of the dressing operation. Procedia CIRP 67:319–324. https://doi.org/10.1016/j.procir.2017.12.220

Junior P, D’addona DM, Aguiar PR, Teti R (2018) Dressing tool condition monitoring through impedance-based sensors: part 1 – PZT diaphragm transducer response and EMI sensing technique. Sensors (Switzerland) 18: . doi: https://doi.org/10.3390/s18124455

Junior P, D’Addona DM, Aguiar P, Teti R (2018) Dressing tool condition monitoring through impedance-based sensors: part 2 – neural networks and K-nearest neighbor classifier approach. Sensors (Switzerland) 18. https://doi.org/10.3390/s18124453

Hocheng H, Tseng HC, Hsieh ML, Lin YH (2018) Tool wear monitoring in single-point diamond turning using laser scattering from machined workpiece. J Manuf Process 31:405–415. https://doi.org/10.1016/j.jmapro.2017.12.007

Balsamo V, Caggiano A, Jemielniak K et al (2016) Multi sensor signal processing for catastrophic tool failure detection in turning. Procedia CIRP 41:939–944. https://doi.org/10.1016/j.procir.2016.01.010

Scheffer C, Kratz H, Heyns PS, Klocke F (2003) Development of a tool wear-monitoring system for hard turning. Int J Mach Tools Manuf 43:973–985. https://doi.org/10.1016/S0890-6955(03)00110-X

Hase A, Wada M, Koga T, Mishina H (2014) The relationship between acoustic emission signals and cutting phenomena in turning process. Int J Adv Manuf Technol 70:947–955. https://doi.org/10.1007/s00170-013-5335-9

Klaic M, Staroveski T, Udiljak T (2014) Tool wear classification using decision trees in stone drilling applications: a preliminary study. Procedia Eng 69:1326–1335. https://doi.org/10.1016/j.proeng.2014.03.125

Dong Wang G, Li N, Kirwa Melly S et al (2019) Monitoring the drilling process of GFRP laminates with carbon nanotube buckypaper sensor. Compos Struct 208:114–126. https://doi.org/10.1016/j.compstruct.2018.10.016

Caggiano A, Angelone R, Napolitano F et al (2018) Dimensionality reduction of sensorial features by principal component analysis for ANN machine learning in tool condition monitoring of CFRP drilling. Procedia CIRP 78:307–312. https://doi.org/10.1016/j.procir.2018.09.072

Patra K, Jha AK, Szalay T et al (2017) Artificial neural network based tool condition monitoring in micro mechanical peck drilling using thrust force signals. Precis Eng 48:279–291. https://doi.org/10.1016/j.precisioneng.2016.12.011

Dai Y, Zhu K (2018) A machine vision system for micro-milling tool condition monitoring. Precis Eng 52:183–191. https://doi.org/10.1016/j.precisioneng.2017.12.006

Hesser DF, Markert B (2019) Tool wear monitoring of a retrofitted CNC milling machine using artificial neural networks. Manuf Lett 19:1–4. https://doi.org/10.1016/j.mfglet.2018.11.001

Alhadeff LL, Marshall MB, Curtis DT, Slatter T (2019) Protocol for tool wear measurement in micro-milling. Wear 420–421:54–67. https://doi.org/10.1016/j.wear.2018.11.018

Zhang XY, Lu X, Wang S et al (2018) A multi-sensor based online tool condition monitoring system for milling process. Procedia CIRP 72:1136–1141. https://doi.org/10.1016/j.procir.2018.03.092

Teti R, Jemielniak K, O’Donnell G, Dornfeld D (2010) Advanced monitoring of machining operations. CIRP Ann - Manuf Technol 59:717–739. https://doi.org/10.1016/j.cirp.2010.05.010

Dias EA, Pereira FB, Ribeiro Filho SLM, Brandão LC (2016) Monitoring of through-feed centreless grinding processes with acoustic emission signals. Measurement 94:71–79. https://doi.org/10.1016/j.measurement.2016.07.075

Thanedar A, Dongre GG, Singh R, Joshi SS (2017) Surface integrity investigation including grinding burns using Barkhausen noise (BNA). J Manuf Process 30:226–240. https://doi.org/10.1016/j.jmapro.2017.09.026

Neslušan M, Čížek J, Kolařík K et al (2017) Monitoring of grinding burn via Barkhausen noise emission in case-hardened steel in large-bearing production. J Mater Process Technol 240:104–117

Yang Z, Yu Z, Xie C, Huang Y (2014) Application of Hilbert–Huang transform to acoustic emission signal for burn feature extraction in surface grinding process. Measurement 47:14–21. https://doi.org/10.1016/j.measurement.2013.08.036

Aguiar PR, Bianchi EC, Canarim RC (2012) Monitoring of grinding burn by acoustic emission. In: InTech. Dr. Wojcie. Rijeka, Croatia, pp 341–364

Yang Z, Yu Z (2013) Experimental study of burn classification and prediction using indirect method in surface grinding of AISI 1045 steel. Int J Adv Manuf Technol 68:2439–2449. https://doi.org/10.1007/s00170-013-4882-4

Neto RFG, Marchi M, Martins C et al (2014) Monitoring of grinding burn by AE and vibration signals. Proc 6th Int Conf Agents Artif Intell:272–279. https://doi.org/10.5220/0004753602720279

Yang Z, Yu Z (2012) Grinding wheel wear monitoring based on wavelet analysis and support vector machine. Int J Adv Manuf Technol 62:107–121. https://doi.org/10.1007/s00170-011-3797-1

Wang Z, Willett P, Aguiar PR, Webster J (2001) Neural network detection of grinding burn from acoustic emission. Int J Mach Tools Manuf 41:283–309. https://doi.org/10.1016/S0890-6955(00)00057-2

Malkin S, Guo C (2007) Thermal analysis of grinding. CIRP Ann - Manuf Technol 56:760–782. https://doi.org/10.1016/j.cirp.2007.10.005

de Aguiar PR, Dotto FRL, Bianchi EC (2005) Study of thresholds to burning in surface grinding process. J Braz Soc Mech Sci Eng 27. https://doi.org/10.1590/S1678-58782005000200007

Marchi M, Baptista FG, Aguiar PR, Bianchi CE (2015) Grinding process monitoring based on electromechanical impedance measurements. Meas Sci Technol 26:045601. https://doi.org/10.1088/0957-0233/26/4/045601

Batista da Silva R, Ferreira FI, Baptista FG, Aguiar PR, Souza Ruzzi R, Hubner HB, Penha Cindra Fonseca M, Bianchi EC (2018) Electromechanical impedance (EMI) technique as alternative to monitor workpiece surface damages after the grinding operation. Int J Adv Manuf Technol 98:2429–2438. https://doi.org/10.1007/s00170-018-2390-2

He B, Wei C, Ding S, Shi Z (2019) A survey of methods for detecting metallic grinding burn. Meas J Int Meas Confed 134:426–439. https://doi.org/10.1016/j.measurement.2018.10.093

Baptista FG, Filho J V. (2011) Piezoelectric transducers applied in structural health monitoring: data acquisition and virtual instrumentation for electromechanical impedance technique. In: InTech, Dr. Farzad. pp 105–128

Castro B, Clerice G, Ramos C et al (2016) Partial discharge monitoring in power transformers using low-cost piezoelectric sensors. Sensors 16:1266. https://doi.org/10.3390/s16081266

Baptista FG, Filho JV (2009) A new impedance measurement system for PZT-based structural health monitoring. IEEE Trans Instrum Meas 58:3602–3608. https://doi.org/10.1109/TIM.2009.2018693

Na WS, Baek J (2018) A review of the piezoelectric electromechanical impedance based structural health monitoring technique for engineering structures. Sensors (Switzerland):18. https://doi.org/10.3390/s18051307

Baptista FG, Filho JV (2010) Optimal frequency range selection for PZT transducers in impedance-based SHM systems. IEEE Sensors J 10:1297–1303. https://doi.org/10.1109/JSEN.2010.2044037

Na S, Lee HK (2013) A multi-sensing electromechanical impedance method for non-destructive evaluation of metallic structures. Smart Mater Struct 22:8pp. https://doi.org/10.1088/0964-1726/22/9/095011

da Silveira RZM, Campeiro LM, Baptista FG (2017) Performance of three transducer mounting methods in impedance-based structural health monitoring applications. J Intell Mater Syst Struct:1045389X1768994. https://doi.org/10.1177/1045389X17689942

Park G, Sohn H, Farrar CR, Inman DJ (2003) Overview of piezoelectric impedance-based health monitoring and path forward. Shock Vib Dig 35:451–463. https://doi.org/10.1177/05831024030356001

Baptista F, Budoya D, Almeida V, Ulson J (2014) An experimental study on the effect of temperature on piezoelectric sensors for impedance-based structural health monitoring. Sensors 14:1208–1227. https://doi.org/10.3390/s140101208

Malkin S, Guo C (2008) Grinding technology: theory and applications of machining with abrasives, 2nd edn. Industrial Press Inc, New York

Cearsolo X, Cabanes I, Sánchez JA et al (2016) Dry-dressing for ecological grinding. J Clean Prod 135:633–643. https://doi.org/10.1016/j.jclepro.2016.06.117

Baumgart C, Heizer V, Wegener K (2018) In-process workpiece based temperature measurement in cylindrical grinding. Procedia CIRP 77:42–45. https://doi.org/10.1016/j.procir.2018.08.206

Marinescu ID, Hitchiner M, Uhlmann E, Rowe WB (2007) Handbook of machining with grinding wheels, 1st edn. CRC Press, New York

Drazumeric R, Badger J, Krajnik P (2014) Geometric, kinematical and thermal analyses of non-round cylindrical grinding. J Mater Process Technol 214:818–827. https://doi.org/10.1016/j.jmatprotec.2013.12.007

Asiltürk I, Çunkaş M (2011) Modeling and prediction of surface roughness in turning operations using artificial neural network and multiple regression method. Expert Syst Appl 38:5826–5832. https://doi.org/10.1016/j.eswa.2010.11.041

Sinha MK, Setti D, Ghosh S, Venkateswara Rao P (2016) An investigation on surface burn during grinding of Inconel 718. J Manuf Process 21:124–133. https://doi.org/10.1016/j.jmapro.2015.12.004

Villares Metals (2017) Plastic Mold steel - N2711M grade

Acknowledgments

The authors would like to thank the Department of Electrical Engineering of Faculty of Engineering, Sao Paulo State University (UNESP), Bauru, SP, Brazil; School of Mechanical Engineering, Federal University of Uberlândia, Uberlândia, Brazil; and School of Integrated Studies, Kansas State University, Salina, KS, USA, for enabling the development of the part of that research that resulted in this work.

Funding

This work was supported in part by the CAPES Foundation, Ministry of Education of Brazil, financially (grant PDSE 88881.190384/2018-01). Rosemar B. da Silva thanks the CAPES for the concession of the PNDP postdoctoral scholarship at the Post-Graduate Program of Electrical Engineering of FEB-UNESP-BAURU (2016–2017), as well as CNPq, for its financial support through the universal demand, process no. 426018/2018-4.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ferreira, F.I., de Aguiar, P.R., da Silva, R.B. et al. Electromechanical impedance (EMI) measurements to infer features from the grinding process. Int J Adv Manuf Technol 106, 2035–2048 (2020). https://doi.org/10.1007/s00170-019-04733-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04733-8