Abstract

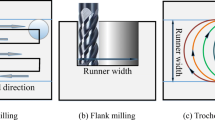

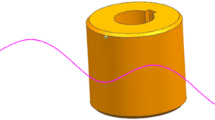

Hyperboloidal-type normal circular-arc gears (HNCGs) are a latest application of circular-arc tooth profile in the gearing with perpendicular non-intersection axes, and the existing software programs provided by the original equipment manufacturers (OEMs) for specific machine tools cannot yet directly support the manufacture of HNCGs. In this paper, a dimension-driven adaptive programming methodology is proposed to automatically carry out the tool-path planning and generate the G-code file for the form milling of HNCGs on general 5-axis CNC machine tools. Based on the mathematical model of tooth surface, the basic strategy for 5-axis form milling of tooth is presented, an interference-free tool path considering both roughing and finishing operations is planned, and furthermore, the tool-path data is transformed to achieve the machine tool coordinates. To quickly respond to the changes of design and machining parameters, a dimension-driven adaptive programming software package is developed to automatically compute the tool path, conduct the post-processing, and generate the G-codes for 5-axis form milling of HNCGs with different specifications, and example verification is carried out to demonstrate the validity of the proposed method.

Similar content being viewed by others

References

Lee YS, Chang TC (1995) 2-Phase approach to global tool interference avoidance in 5-axis CNC machining. Comput Aided Des 27(10):715–729

Lee YS (1997) Admissible tool orientation control of gouging avoidance for 5-axis complex surface machining. Comput Aided Des 29(7):507–521

Lee YS (1998) Non-isoparametric tool path planning by machining strip evaluation for 5-axis sculptured surface machining. Comput Aided Des 30(7):559–570

Sun YW, Zhao Y, Bao YR, Guo DM (2015) A smooth curve evolution approach to the feedrate planning on 5-axis toolpath with geometric and kinematic constraints. Int J Mach Tools Manuf 97:86–97

Sun YW, Xu JT, Jin CN, Guo DM (2016) Smooth tool path generation for 5-axis CNC machining of triangular mesh surface with nonzero genus. Comput Aided Des 79:60–74

Xu JT, Zhang DY, Sun YW (2019) Kinematics performance oriented smoothing method to plan tool orientations for 5-axis ball-end CNC machining. Int J Mech Sci 157–158:293–303

Wang B, Fan MX, Sun X, Li JB, Xu AJ, Li GG, Yang JJ (2016) Cutter position calculation of machining equal base circle bevel gears with a pot-shaped milling cutter. Int Adv Manuf Technol 87:2625–2637

Álvarez A, Calleja A, Ortega N, de Lacalle LNL (2018) Five-axis milling of large spiral bevel gears: toolpath definition, finishing, and shape errors. Metals 8:353. https://doi.org/10.3390/met8050353

Deng XZ, Li GG, Wei BY, Deng J (2014) Face-milling spiral bevel gear tooth surfaces by application of 5-axis CNC machine tool. Int Adv Manuf Technol 71:1049–1057

Shih YP, Zhang CX (2017) Manufacture of spiral bevel gears using standard profile angle blade cutters on a five axis computer numerical control machine. J Manuf Sci Eng 139(6):061017 (14 pages)

Piao CD, Lee CS, Cho KZ, Park GR (2004) Automatic NC-data generation method for 5-axis cutting of turbine-blades by finding safe heel-angles and adaptive path-intervals. KSME Int J 18(5):753–761

Zhou M, Zheng GL, Chen ZC (2016) An automated CNC programming approach to machining pocket with complex islands and boundaries by using multiple cutters in hybrid tool path patterns. Int Adv Manuf Technol 83:407–420

Chen ZC, Wasif M (2015) A generic and theoretical approach to programming and post-processing for hypoid gear machining on multi-axis CNC face-milling machines. Int Adv Manuf Technol 81:135–148

Shen YB, Liu X (2018) Computer-integrated shaving processing for spiroid face gear on a 5-axis CNC machine. Int Adv Manuf Technol 97:1061–1070

Chen HJ, Zhang XP, Cai X, Ju ZL, Qu C, Shi DH (2016) Computerized design, generation and simulation of meshing and contact of hyperboloidal-type normal circular-arc gears. Mech Mach Theory 96:127–145

Chen HJ, Duan ZY, Wu HJ, Liu J (2006) Study on the general principle of normal circular-arc gear transmission. Mech Mach Theory 41:1424–1442

Acknowledgments

All the authors expresses sincere gratitude to Prof. Jian Liu of Dalian university of technology of China.

Funding

This work is funded by National Natural Science Foundation of China (No.51105210) and the Priority Academic Program Development of Jiangsu Higher Education Institutions (No.(2018)192).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yan, G., Chen, H., Zhang, X. et al. A dimension-driven adaptive programming for tool-path planning and post-processing in 5-axis form milling of hyperboloidal-type normal circular-arc gears. Int J Adv Manuf Technol 106, 2735–2746 (2020). https://doi.org/10.1007/s00170-019-04723-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04723-w