Abstract

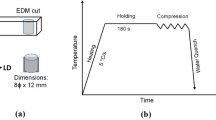

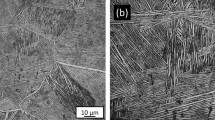

Isothermal compression testing was carried out on newly developed low-cost (α + β) Ti-4.5Al-1 V-3Fe alloy with lamellar initial microstructure using a Gleeble 3500 thermomechanical simulator. The tests were performed under different conditions of strain rate (0.001, 0.01, 0.1, 1 and 10 s −1), deformation temperature (750, 800, 850, 900 and 950 °C) and a constant total strain of 0.6. Stress-strain analysis, constitutive constant calculations, processing maps and microstructural validation were used to understand the hot working behaviour of the alloys and the underlying softening mechanisms. The results show that the deformation behaviour was significantly influenced by the deformation parameters. Two main softening mechanisms, which have been reported in existing commercial alloys with a fully lamellar structure, also controlled the deformation behaviour of the Ti-4.5Al-1 V-3Fe alloy. Lath bending and rotation caused flow softening at low temperatures and high strain rates, while dynamic globularisation led to flow softening at the higher temperatures and low strain rates. The optimum condition for hot working of the alloy in the safe deformation region was found at ~890–905 °C and 0.003–0.01 s −1. The region of instability identified at ~875–930 °C/0.15–0.4 s −1 should be avoided during hot working to prevent flow localisation, shear cracks, cavitation and other instabilities that may arise.

Similar content being viewed by others

References

Donachie MJ (2000) Titanium: a technical guide, 2nd edn. ASM International

Leyens C, Peters M (2003) Titanium and titanium alloys: fundamentals and application. WILEY-VCH, Germany

Prozesky DJ, Bodunrin MO, Chown LH (2017) Hot-deformation behaviour of α + β Ti-Al-V-Fe experimental alloys. AIP Conf Proc 1896:160019. https://doi.org/10.1063/1.5008194

Esteban PG, Ruiz-Navas EM, Bolzoni L, Gordo E (2008) Low-cost titanium alloys? Iron may hold the answers. Met Powder Rep 63:24–27. https://doi.org/10.1016/S0026-0657(09)70040-2

Froes FH(S), Friedrich H, Kiese J, Bergoint D (2004) Titanium in the family automobile: the cost challenge. JOM 56:40–44

Fujii H, Takahashi K, Yamashita Y (2003) Application of titanium and its alloys for automobile parts. Shinnittetsu Giho:62–67

Niinomi M (2003) Recent research and development in titanium alloys for biomedical applications and healthcare goods. Sci Technol Adv Mater 4:445–454. https://doi.org/10.1016/j.stam.2003.09.002

Fujii H, Takahashi K (2002) Development of high performance Ti-Fe-Al alloy series. NIPPON STEEL

Fujii H, Fujisawa K, Ishil M, Yamashita Y (2002) Development of low-cost high-strength Ti-Fe-O-N alloy series. NIPPON STEEL

Seshacharyulu T, Medeiros SC, Frazier WG, Prasad YVRK (2000) Hot working of commercial Ti–6Al–4 V with an equiaxed α–β microstructure: materials modeling considerations. Mater Sci Eng A 284:184–194. https://doi.org/10.1016/S0921-5093(00)00741-3

Veiga C, Davim JP, Loureiro AJR (2013) Review on machinability of titanium alloys: the process perspective. Rev Adv Mater Sci 34:148–164

Esteban PG, Bolzoni L, Ruiz-Navas EM, Gordo E (2011) PM processing and characterisation of Ti–7Fe low cost titanium alloys. Powder Metall 54:242–252. https://doi.org/10.1179/174329009X457063

Bolzoni L, Herraiz E, Ruiz-Navas EM, Gordo E (2014) Study of the properties of low-cost powder metallurgy titanium alloys by 430 stainless steel addition. Mater Des 60:628–636. https://doi.org/10.1016/j.matdes.2014.04.019

Benson LL, Mellor I, Jackson M (2016) Direct reduction of synthetic rutile using the FFC process to produce low-cost novel titanium alloys. J Mater Sci 51:4250–4261. https://doi.org/10.1007/s10853-015-9718-1

Xu X, Nash P, Mangabhai D (2017) Characterization and sintering of Armstrong process titanium powder. JOM 69:770–775. https://doi.org/10.1007/s11837-016-2238-x

Weston NS, Jackson M (2017) FAST-forge − a new cost-effective hybrid processing route for consolidating titanium powder into near net shape forged components. J Mater Process Technol 243:335–346. https://doi.org/10.1016/j.jmatprotec.2016.12.013

Carman A, Zhang LC, Ivasishin OM et al (2011) Role of alloying elements in microstructure evolution and alloying elements behaviour during sintering of a near-β titanium alloy. Mater Sci Eng A 528:1686–1693. https://doi.org/10.1016/j.msea.2010.11.004

Lütjering G, Williams JC (2007) Engineering materials: titanium, Second. Springer, Berlin Heidelberg Newyork

Lütjering G (1998) Influence of processing on microstructure and mechanical properties of (α + β) titanium alloys. Mater Sci Eng A 243:32–45. https://doi.org/10.1016/S0921-5093(97)00778-8

Duan Y, Li P, Xue K et al (2007) Flow behavior and microstructure evolution of TB8 alloy during hot deformation process. Trans Nonferrous Met Soc China 17:1199–1204. https://doi.org/10.1016/S1003-6326(07)60249-0

Froes FHS, Gungor MN, Imam MA (2007) Cost-affordable titanium: the component fabrication perspective. JOM 59:28–31. https://doi.org/10.1007/s11837-007-0074-8

samaterials (2014) Why titanium is so expensive. In: Stanf. Adv. Mater. https://samaterials.wordpress.com/2014/07/29/why-titanium-is-so-expensive/. Accessed 22 Oct 2016

Boyer RR (2010) Titanium and its alloys: metallurgy, heat treatment and alloy characteristics. In: Encyclopedia of Aerospace Engineering. American Cancer Society

Bloomberg One battery material sector is cheering for lower prices. In: Eng. News. https://www.engineeringnews.co.za/article/one-battery-material-sector-is-cheering-for-lower-prices-2019-09-19. Accessed 11 Nov 2019

Bodunrin MO, Chown LH, Merwe JW van der, Alaneme KK (2019) Corrosion behaviour of low-cost Ti–4.5Al–xV–yFe alloys in sodium chloride and sulphuric acid solutions. Corros Eng Sci Technol 0:1–12. https://doi.org/10.1080/1478422X.2019.1654218

Bolzoni L, Esteban PG, Ruiz-Navas EM, Gordo E (2012) Mechanical behaviour of pressed and sintered titanium alloys obtained from master alloy addition powders. J Mech Behav Biomed Mater 15:33–45. https://doi.org/10.1016/j.jmbbm.2012.05.019

Lin C-W, Ju C-P, Chern Lin J-H (2005) A comparison of the fatigue behavior of cast Ti-7.5Mo with c.p. titanium, Ti-6Al-4 V and Ti-13Nb-13Zr alloys. Biomaterials 26:2899–2907. https://doi.org/10.1016/j.biomaterials.2004.09.007

Zhang L-C, Chen L-Y (2019) A review on biomedical titanium alloys: recent progress and prospect. Adv Eng Mater 21:1801215. https://doi.org/10.1002/adem.201801215

Bettles CJ, Tomus D, Gibson MA (2011) The role of microstructure in the mechanical behaviour of Ti–1.6 wt.%Fe alloys containing O and N. Mater Sci Eng A 528:4899–4909. https://doi.org/10.1016/j.msea.2011.03.030

Nochovnaya NA, Isaichev AV, Antashev VG (2008) Foundations of the development of economically alloyed widely applicable titanium alloys. Mater Sci 44:396–399. https://doi.org/10.1007/s11003-008-9081-3

Balasundar I, Raghu T, Kashyap BP (2013) Processing map for a cast and homogenized near alpha titanium alloy. Int J Mater Form 8:85–97. https://doi.org/10.1007/s12289-013-1150-y

Sen I, Tamirisakandala S, Miracle DB, Ramamurty U (2007) Microstructural effects on the mechanical behavior of B-modified Ti–6Al–4 V alloys. Acta Mater 55:4983–4993. https://doi.org/10.1016/j.actamat.2007.05.009

Choubey A, Balasubramaniam R, Basu B (2004) Effect of replacement of V by Nb and Fe on the electrochemical and corrosion behavior of Ti–6Al–4 V in simulated physiological environment. J Alloys Compd 381:288–294. https://doi.org/10.1016/j.jallcom.2004.03.096

Bolzoni L, Ruiz-Navas EM, Gordo E (2016) Understanding the properties of low-cost iron-containing powder metallurgy titanium alloys. Mater Des 110:317–323. https://doi.org/10.1016/j.matdes.2016.08.010

Bodunrin MO, Chown LH, van der Merwe JW, Alaneme KK (2018) Corrosion behaviour of Ti-Al-xV-yFe experimental alloys in 3.5 wt% NaCl and 3.5 M H2SO4. Mater Corros 69:770–780. https://doi.org/10.1002/maco.201709709

Roebuck B, Lord JD, Brooks M et al (2006) Measurement of flow stress in hot axisymmetric compression tests. Mater High Temp 23:59–83. https://doi.org/10.1179/mht.2006.005

Sellars CM, Tegart WJ (1966) On the mechanism of hot deformation. Acta Metall 14:1136–1138. https://doi.org/10.1016/0001-6160(66)90207-0

Zener C, Hollomon JH (1944) Effect of strain rate upon plastic flow of steel. J Appl Phys 15:22–32. https://doi.org/10.1063/1.1707363

McQueen HJ, Ryan ND (2002) Constitutive analysis in hot working. Mater Sci Eng A 322:43–63. https://doi.org/10.1016/S0921-5093(01)01117-0

Nkhoma RKC, Siyasiya CW, Stumpf WE (2014) Hot workability of AISI 321 and AISI 304 austenitic stainless steels. J Alloys Compd 595:103–112. https://doi.org/10.1016/j.jallcom.2014.01.157

Lin YC, Chen X-M (2011) A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater Des 32:1733–1759. https://doi.org/10.1016/j.matdes.2010.11.048

Shi J, Sun W, Jiang J, Zhang Y (2016) Influence of chloride concentration and pre-passivation on the pitting corrosion resistance of low-alloy reinforcing steel in simulated concrete pore solution. Constr Build Mater 111:805–813. https://doi.org/10.1016/j.conbuildmat.2016.02.107

Prasad YVRK, Seshacharyulu T, Medeiros SC, Frazier WG (2000) Effect of preform microstructure on the hot working mechanisms in ELI grade Ti–6Al–4 V: transformed β v. equiaxed (α + β). Mater Sci Technol 16:511–516. https://doi.org/10.1179/026708300101508171

Prasad YVRK, Rao KP, Sasidhara S (2015) Hot working guide : a compendium of processing maps. ASM International

Narayana Murty SVS, Nageswara Rao B, Kashyap BP (2000) Instability criteria for hot deformation of materials. Int Mater Rev 45:15–26. https://doi.org/10.1179/095066000771048782

Ma X, Zeng W, Xu B et al (2012) Characterization of the hot deformation behavior of a Ti–22Al–25Nb alloy using processing maps based on the Murty criterion. Intermetallics 20:1–7. https://doi.org/10.1016/j.intermet.2011.08.027

Zong YY, Shan DB, Xu M, Lv Y (2009) Flow softening and microstructural evolution of TC11 titanium alloy during hot deformation. J Mater Process Technol 209:1988–1994. https://doi.org/10.1016/j.jmatprotec.2008.04.063

Liu J, Zeng W, Lai Y, Jia Z (2014) Constitutive model of Ti17 titanium alloy with lamellar-type initial microstructure during hot deformation based on orthogonal analysis. Mater Sci Eng A 597:387–394. https://doi.org/10.1016/j.msea.2013.12.076

Seshacharyulu T, Medeiros SC, Frazier WG, Prasad YVRK (2002) Microstructural mechanisms during hot working of commercial grade Ti–6Al–4 V with lamellar starting structure. Mater Sci Eng A 325:112–125. https://doi.org/10.1016/S0921-5093(01)01448-4

Song H, Zhang S, Cheng M (2014) Dynamic globularization prediction during cogging process of large size TC11 titanium alloy billet with lamellar structure. Def Technol 10:40–46. https://doi.org/10.1016/j.dt.2014.01.003

Seshacharyulu T, Medeiros SC, Morgan JT et al (2000) Hot deformation and microstructural damage mechanisms in extra-low interstitial (ELI) grade Ti–6Al–4 V. Mater Sci Eng A 279:289–299. https://doi.org/10.1016/S0921-5093(99)00173-2

Bodunrin MO, Chown LH, van der Merwe JW, Alaneme KK (2018) Hot working of Ti-6Al-4 V with a complex initial microstructure. Int J Mater Form. 12:857–874. https://doi.org/10.1007/s12289-018-1457-9

Wu C, Yang H, Fan X, Sun Z (2011) Dynamic globularization kinetics during hot working of TA15 titanium alloy with colony microstructure. Trans Nonferrous Met Soc China 21:1963–1969. https://doi.org/10.1016/S1003-6326(11)60957-6

Li C, Zhang X, Li Z, Zhou K-C (2013) Hot Deformation of Ti-5Al-5Mo-5 V-1Cr-1Fe Near β Titanium Alloys Containing Thin and Thick Lamellar α Phase. Mater Sci Eng A 573:75–83. https://doi.org/10.1016/j.msea.2013.02.033

Bai XF, Zhao YQ, Zeng WD et al (2014) Characterization of hot deformation behavior of a biomedical titanium alloy TLM. Mater Sci Eng A 598:236–243. https://doi.org/10.1016/j.msea.2014.01.005

Weiss I, Semiatin SL (1998) Thermomechanical processing of beta titanium alloys—an overview. Mater Sci Eng A 243:46–65. https://doi.org/10.1016/S0921-5093(97)00783-1

Bodunrin MO (2018) Hot deformation and corrosion behaviour of low-cost α + β titanium alloys with aluminium, vanadium and iron additions. Thesis

Wang K, Zeng W, Zhao Y, Lai Y, Zhou Y (2010) Hot working of Ti-17 titanium alloy with lamellar starting structure using 3-D processing maps. J Mater Sci 45:5883–5891. https://doi.org/10.1007/s10853-010-4667-1

Goetz RL, Semiatin SL (2001) The adiabatic correction factor for deformation heating during the uniaxial compression test. J Mater Eng Perform 10:710–717. https://doi.org/10.1361/105994901770344593

Calvert E, Pollard J, Jackson M et al (2015) Determining a Flow Stress Model for High Temperature Deformation of Ti-6Al-4 V. In: Materials Science Forum. Trans Tech Publications, Switzerland, Port Elizabeth, South Africa, pp 441–446

Lin YC, Chen M-S, Zhong J (2008) Constitutive modeling for elevated temperature flow behavior of 42CrMo steel. Comput Mater Sci 42:470–477. https://doi.org/10.1016/j.commatsci.2007.08.011

Akbari Z, Mirzadeh H, Cabrera J-M (2015) A simple constitutive model for predicting flow stress of medium carbon microalloyed steel during hot deformation. Mater Des 77:126–131. https://doi.org/10.1016/j.matdes.2015.04.005

Semiatin SL, Seetharaman V, Weiss I (1998) Hot workability of titanium and titanium aluminide alloys—an overview. Mater Sci Eng A 243:1–24. https://doi.org/10.1016/S0921-5093(97)00776-4

Cabrera JM, Jonas JJ, Prado JM (1996) Flow behaviour of medium carbon microalloyed steel under hot working conditions. Mater Sci Technol 12:579–585. https://doi.org/10.1179/mst.1996.12.7.579

Mirzadeh H (2015) Simple physically-based constitutive equations for hot deformation of 2024 and 7075 aluminum alloys. Trans Nonferrous Met Soc China 25:1614–1618. https://doi.org/10.1016/S1003-6326(15)63765-7

Mirzadeh H, Cabrera JM, Najafizadeh A (2011) Constitutive relationships for hot deformation of austenite. Acta Mater 59:6441–6448. https://doi.org/10.1016/j.actamat.2011.07.008

Frost HJ, Ashby MF (1982) Deformation-mechanism maps: the plasticity and creep of metals and ceramics. Pergamon Press

Shi H, McLaren AJ, Sellars CM et al (1997) Constitutive equations for high temperature flow stress of aluminium alloys. Mater Sci Technol 13:210–216. https://doi.org/10.1179/mst.1997.13.3.210

Seetharaman V, Semiatin SL (1997) Plastic-flow and microstructure evolution during hot deformation of a gamma titanium aluminide alloy. Metall Mater Trans A 28:2309–2321. https://doi.org/10.1007/s11661-997-0188-1

Semiatin SL, Seetharaman V, Ghosh AK (1999) Plastic flow, microstructure evolution, and defect formation during primary hot working of titanium and titanium aluminide alloys with lamellar colony microstructures. Philos Trans R Soc Lond Math Phys Eng Sci 357:1487–1512. https://doi.org/10.1098/rsta.1999.0386

Bryant WA (1975) Correlation of data on the hot deformation of Ti-6Al-4 V. J Mater Sci 10:1793–1797

Briottet L, Jonas JJ, Montheillet F (1996) A mechanical interpretation of the activation energy of high temperature deformation in two phase materials. Acta Mater 44:1665–1672. https://doi.org/10.1016/1359-6454(95)00257-X

Porntadawit J, Uthaisangsuk V, Choungthong P (2014) Modeling of flow behavior of Ti–6Al–4 V alloy at elevated temperatures. Mater Sci Eng A 599:212–222. https://doi.org/10.1016/j.msea.2014.01.064

Xia Y, Long S, Zhou Y et al (2016) Identification for the optimal working parameters of Ti-6Al-4 V-0.1Ru alloy in a wide deformation condition range by processing maps based on DMM. Mater Res 19:1449–1460. https://doi.org/10.1590/1980-5373-mr-2016-0448

Junhui C, He Y, Zhichao S et al (2012) Flow behavior and constitutive model using piecewise function of strain for TC11 alloy. Rare Met Mater Eng 41:397–401. https://doi.org/10.1016/S1875-5372(12)60035-6

Luo J, Li M, Li H, Yu W (2009) Effect of the strain on the deformation behavior of isothermally compressed Ti–6Al–4 V alloy. Mater Sci Eng A 505:88–95. https://doi.org/10.1016/j.msea.2008.11.001

Guan RG, Je YT, Zhao ZY (1980-2015) Lee CS (2012) Effect of microstructure on deformation behavior of Ti–6Al–4 V alloy during compressing process. Mater Des 36:796–803. https://doi.org/10.1016/j.matdes.2011.11.057

Momeni A, Abbasi SM (2010) Effect of hot working on flow behavior of Ti–6Al–4 V alloy in single phase and two phase regions. Mater Des 31:3599–3604. https://doi.org/10.1016/j.matdes.2010.01.060

Peng X, Guo H, Shi Z et al (2013) Constitutive equations for high temperature flow stress of TC4-DT alloy incorporating strain, strain rate and temperature. Mater Des 50:198–206. https://doi.org/10.1016/j.matdes.2013.03.009

Souza PM, Beladi H, Rolfe B et al (2015) Softening behavior of Ti6Al4V alloy during hot deformation. In: Materials Science Forum. Materials Science Forum, Port Elizabeth, South Africa, pp 407–412

Balasundar I, Raghu T, Kashyap BP (2013) Modeling the hot working behavior of near-α titanium alloy IMI 834. Prog Nat Sci Mater Int 23:598–607. https://doi.org/10.1016/j.pnsc.2013.11.004

Wanjara P, Jahazi M, Monajati H et al (2005) Hot working behavior of near-α alloy IMI834. Mater Sci Eng A 396:50–60. https://doi.org/10.1016/j.msea.2004.12.005

Li M, Pan H, Lin Y, Luo J (2007) High temperature deformation behavior of near alpha Ti–5.6Al–4.8Sn–2.0Zr alloy. J Mater Process Technol 183:71–76. https://doi.org/10.1016/j.jmatprotec.2006.10.002

Ding R, Guo ZX, Wilson A (2002) Microstructural evolution of a Ti–6Al–4 V alloy during thermomechanical processing. Mater Sci Eng A 327:233–245. https://doi.org/10.1016/S0921-5093(01)01531-3

Guo B, Semiatin SL, Jonas JJ (2019) Dynamic transformation during the high temperature deformation of two-phase titanium alloys. Mater Sci Eng A 761:138047. https://doi.org/10.1016/j.msea.2019.138047

Murty SVSN, Rao BN, Kashyap BP (2002) Development and validation of a processing map for zirconium alloys. Model Simul Mater Sci Eng 10:503. https://doi.org/10.1088/0965-0393/10/5/303

Prasad YVRK (2003) Processing maps: A status report. J Mater Eng Perform 12:638–645. https://doi.org/10.1361/105994903322692420

Prasad YVRK, Gegel HL, Doraivelu SM et al (1984) Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242. Metall Trans A 15:1883–1892. https://doi.org/10.1007/BF02664902

Wang K, Zeng W, Zhao Y et al (2010) Dynamic globularization kinetics during hot working of Ti-17 alloy with initial lamellar microstructure. Mater Sci Eng A 527:2559–2566. https://doi.org/10.1016/j.msea.2010.01.034

Li H, Zhao Z, Guo H et al (2017) Effect of initial alpha lamellar thickness on deformation behavior of a near-α high-temperature alloy during thermomechanical processing. Mater Sci Eng A 682:345–353. https://doi.org/10.1016/j.msea.2016.11.063

Weiss I, Semiatin SL (1999) Thermomechanical processing of alpha titanium alloys—an overview. Mater Sci Eng A 263:243–256. https://doi.org/10.1016/S0921-5093(98)01155-1

Semiatin SL, Seetharaman V, Weiss I (1997) The thermomechanical processing of alpha/beta titanium alloys. JOM 49:33–39. https://doi.org/10.1007/BF02914711

Guan RG, Je YT, Zhao ZY, Lee CS (2012) Effect of microstructure on deformation behavior of Ti–6Al–4 V alloy during compressing process. Mater Des 36:796–803. https://doi.org/10.1016/j.matdes.2011.11.057

Fan JK, Kou HC, Lai MJ et al (2013) Characterization of hot deformation behavior of a new near beta titanium alloy: Ti-7333. Mater Des 49:945–952. https://doi.org/10.1016/j.matdes.2013.02.044

Funding

The authors wish to acknowledge the African Materials Science and Engineering Network (A Carnegie-IAS RISE network), the DST-NRF Centre of Excellence in Strong Materials and African Academy of Sciences Grant No [ARPDF 18-03] for providing the financial support to carry out this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bodunrin, M.O., Chown, L.H., van der Merwe, J.W. et al. Hot working behaviour of experimental Ti-4.5Al-1 V-3Fe alloy with initial lamellar microstructure. Int J Adv Manuf Technol 106, 1901–1916 (2020). https://doi.org/10.1007/s00170-019-04718-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04718-7