Abstract

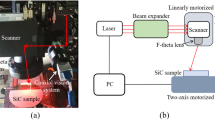

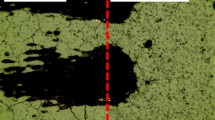

Silicon carbide (SiC) is heavily used in the industry due to its resistance to chemical wear and excellent mechanical properties such as high hardness and high stiffness. However, these properties make it difficult to produce micro and nanostructures on the surface of SiC by conventional methods. In this study, high-density microcones that protrude ~ 10 μm above the initial surface have been fabricated by nanosecond pulsed Nd:YAG laser irradiation (λ = 532 nm) on reaction-bonded SiC. Geometrically aligned cones were also fabricated by modifying the laser scanning path, and effect of different parameters such as pulse frequency, laser fluence was studied. It was observed that the surface morphology of microcones was affected by the pulse width and beam overlap. X-ray spectroscopy and Raman spectroscopy showed that the microcones were mainly composed of silicon. Formation of these cone structures made the surface highly superhydrophilic with a contact angle of ~ 0°.

Similar content being viewed by others

References

Suyama S, Itoh Y, Tsuno K, Ohno K (2005) Φ 650 mm optical space mirror substrate of high-strength reaction-sintered silicon carbide. Proc. SPIE:5868. https://doi.org/10.1117/12.616043

Toulemont Y, Breysse J, Piepot D, Miura S (2004) The 3.5 m all SiC telescope for SPICA. SPIE 5487:1001–1012. https://doi.org/10.1117/12.551405

Xing Y, Deng J, Wu Z, Wu F (2017) High friction and low wear properties of laser-textured ceramic surface under dry friction. Opt Laser Technol 93:24–32. https://doi.org/10.1016/j.optlastec.2017.01.032

Murzin SP, Balyakin VB (2017) Microstructuring the surface of silicon carbide ceramic by laser action for reducing friction losses in rolling bearings. Opt Laser Technol 88:96–98. https://doi.org/10.1016/j.optlastec.2016.09.007

Geiger M, Roth S, Becker W (1998) Influence of laser-produced microstructures on the tribological behaviour of ceramics. Surf Coatings Technol 100–101:17–22. https://doi.org/10.1016/S0257-8972(97)00581-1

Kondrashov V, Rühe J (2014) Microcones and nanograss: toward mechanically robust superhydrophobic surfaces. Langmuir 30:4342–4350. https://doi.org/10.1021/la500395e

Li XM, Reinhoudt D, Crego-Calama M (2007) What do we need for a superhydrophobic surface? a review on the recent progress in the preparation of superhydrophobic surfaces. Chem. Soc. Rev. 36:1350–1368

Younkin R, Carey JE, Mazur E, Levinson JA, Friend CM (2003) Infrared absorption by conical silicon microstructures made in a variety of background gases using femtosecond-laser pulses. J Appl Phys 93:2626–2629. https://doi.org/10.1063/1.1545159

Crouch CH, Carey JE, Warrender JM, Aziz MJ, Mazur E (2004) Comparison of structure and properties of femtosecond and nanosecond laser-structured silicon. Appl Phys Lett 84:1850–1852. https://doi.org/10.1063/1.1667004

Bäuerle D (2000) Laser Processing and Chemistry. Springer, Berlin

Brown MS, Arnold CB (2010) Fundamentals of laser-material interaction and application to multiscale surface modification. In: Sugioka K, Meunier M, Piqué A (eds) Laser Precision Microfabrication. Springer Series in Materials Science, vol 135. Springer, Berlin, Heidelberg, pp 91–120

Ness JN, Page TF (1986) Microstructural evolution in reaction-bonded silicon carbide. J Mater Sci 21:1377–1397. https://doi.org/10.1007/BF00553278

Humphreys RG, Signals R, Establishment R et al (1981) ReceDed 22. Energy 39:163–167

Philipp HR, Taft EA (1960) Silicon carbide – a high temperature semiconductor. In: O'Connor JR, Smiltens J (eds) . Pergamon Press, Oxford, London, New York, Paris, p 366

Groth R, Kauer E (1961) Absorption freier Ladungsträger in CdS. Phys Status Solidi 1:650–655. https://doi.org/10.1002/pssb.19610010609

Watanabe N, Kimoto T, Suda J (2014) Temperature dependence of optical absorption coefficient of 4H- and 6H-SiC from room temperature to 300 °C. Jpn J Appl Phys 53:12–15. https://doi.org/10.7567/JJAP.53.108003

Choyke WJ, Patrick L (1960) Silicon carbide – a high temperature semiconductor. In: O'Connor JR, Smiltens J (eds) . Pergamon Press, Oxford, London, New York, Paris, p 306

Yu G, Levinshtein ME, Rumyantsev SL (2001) Properties of Advanced SemiconductorMaterials GaN, AlN, SiC, BN, SiC, SiGe . Eds. Levinshtein M.E., Rumyantsev S.L., Shur M.S., John Wiley & Sons, Inc., New York. pp 93-148.

Duc DH, Naoki I, Kazuyoshi F (2013) A study of near-infrared nanosecond laser ablation of silicon carbide. Int J Heat Mass Transf 65:713–718. https://doi.org/10.1016/j.ijheatmasstransfer.2013.06.050

Samant AN, Daniel C, Chand RH, Blue CA, Dahotre NB (2009) Computational approach to photonic drilling of silicon carbide. Int J Adv Manuf Technol 45:704–713. https://doi.org/10.1007/s00170-009-2004-0

Fedorenko L, Medvid’ A, Yusupov M, Yukhimchuck V, Krylyuk S, Evtukh A (2008) Nanostructures on SiC surface created by laser microablation. Appl Surf Sci 254:2031–2036. https://doi.org/10.1016/j.apsusc.2007.08.048

Cappelli E, Orlando S, Mattei G, Montozzi M, Pinzari F, Sciti D (1999) Surface modifications of carbide ceramics induced by pulsed laser treatments. Appl Phys A Mater Sci Process 69:515–519. https://doi.org/10.1007/s003399900329

Shigematsu I, Kanayama K, Tsuge A, Nakamura M (1998) Analysis of constituents generated with laser machining of Si3N4and SiC. J Mater Sci Lett 17:737–739. https://doi.org/10.1023/A:1006606810476

Bai Y, Li L, Xue D, Zhang X (2016) Rapid fabrication of a silicon modification layer on silicon carbide substrate. Appl Opt 55:5814. https://doi.org/10.1364/ao.55.005814

Dutto C, Fogarassy E, Mathiot D (2001) Numerical and experimental analysis of pulsed excimer laser processing of silicon carbide. Appl Surf Sci 184:362–366. https://doi.org/10.1016/S0169-4332(01)00518-9

Chen SC, Cahill DG, Grigoropoulos CP (2002) Melting and surface deformation in pulsed laser surface micromodification of Ni-P Disks. J Heat Transfer 122:107. https://doi.org/10.1115/1.521441

György E, Mihailescu IN, Serra P, P´erez del pino A, Morenza JL (2002) Crown-like structure development on titanium exposed to multipulse Nd:YAG laser irradiation. Appl Phys A Mater Sci Process. https://doi.org/10.1007/s003390201307, 74, 755, 759

Taylor LL, Qiao J, Qiao J (2016) Optimization of femtosecond laser processing of silicon via numerical modeling. Opt. Mater. Express 6:2745–2758. https://doi.org/10.1364/OME.6.002745

Bradby JE, Williams JS, Wong-Leung J, Swain MV, Munroe P (2002) Nanoindentation-induced deformation of Ge. Appl Phys Lett 80:2651–2653. https://doi.org/10.1063/1.1469660

Koch K, Barthlott W (2009) Superhydrophobic and superhydrophilic plant surfaces: an inspiration for biomimetic materials. Philos Trans R Soc A Math Phys Eng Sci 367:1487–1509. https://doi.org/10.1098/rsta.2009.0022

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Meshram, T., Yan, J. Generation of microcones on reaction-bonded silicon carbide by nanosecond pulsed laser irradiation. Int J Adv Manuf Technol 108, 1039–1048 (2020). https://doi.org/10.1007/s00170-019-04672-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04672-4