Abstract

This paper focusses on understanding laser-NBR rubber interactions in particular the effect of laser wavelength and pulse width on material removal and thermal damage. Three lasers with wavelengths at 355 nm, 795 nm and 1064 nm and pulse duration at 30 ns, 10 ps and 130 fs, respectively, have been investigated for their optical absorption, heat conduction and their material removal mechanisms in high aspect ratio drilling of NBR rubber. It is interesting to find that under certain conditions, the ultrashort pulse lasers (both the femtosecond and picosecond lasers) did not lead to better results than the nanosecond UV laser in drilling hole profile (straightness and thermal damage), aspect ratio and amount of the ablated material re-deposition on the substrate surfaces. The results implied that there is heat conduction and thermal damage even with ultrashort laser pulses when the processing conditions are not appropriate. Firing laser pulses intermittently was shown to reduce thermal accumulation. Experimental studies showed that the 355-nm Nd:YAG laser (UV laser) achieved higher material removal rate with high aspect ratio as compared to the ultrashort laser pulses in drilling the NBR substrates.

Similar content being viewed by others

References

Girardot J et al (2013) Investigation of delamination mechanisms during a laser drilling on a cobalt-base superalloy. J Mater Process Technol 213(10):1682–1691

Goyal R, Dubey AK (2014) Hybrid Approach for Modeling and Optimization of Hole Taper During Laser Trepan Drilling of Ti-6Al-4V Alloy Sheet. Procedia Mater Sci 5:1781–1790

Stephen A et al (2014) High Speed Laser Micro Drilling for Aerospace Applications. Procedia CIRP 24:130–133

Morar NI et al (2018) Investigation of recast and crack formation in laser trepanning drilling of CMSX-4 angled holes. Int J Adv Manuf Technol 95(9):4059–4070

Iba S, Kato Y, Sekitani T, Kawaguchi H, Sakurai T, Someya T (2006) Use of laser drilling in the manufacture of organic inverter circuits. Anal Bioanal Chem 384(2):374–377

Bharatish A et al (2014) Laser Microdrilling of Thermal Barrier Coatings. Procedia Mater Sci 5:1005–1014

Begic-Hajdarevic D, Bijelonja I (2015) Experimental and Numerical Investigation of Temperature Distribution and Hole Geometry during Laser Drilling Process. Procedia Eng 100:384–393

Bahar ND, Marimuthu S, Yahya WJ (2016) Pulsed Nd: YAG laser drilling of aerospace materials (Ti-6Al-4V). IOP Conference Series: Materials Science and Engineering 152(1):012056

Gupta U, Nath AK, Bandyopadhyay PP (2016) Laser micro-hole drilling in thermal barrier coated nickel based superalloy. IOP Conference Series: Materials Science and Engineering 149:012076

Dyer PE, Waldeck I, Roberts GC (1997) Fine-hole drilling in Upilex polyimide and glass by TEA CO2laser ablation. J Phys D Appl Phys 30(6):L19

Brusberg L et al (2012) Advances in CO2-Laser Drilling of Glass Substrates. Phys Procedia 39:548–555

Wlodarczyk KL et al (2016) Picosecond laser cutting and drilling of thin flex glass. Opt Lasers Eng 78:64–74

Walther K, Brajdic M, Kreutz EW (2008) Enhanced processing speed in laser drilling of stainless steel by spatially and temporally superposed pulsed Nd:YAG laser radiation. Int J Adv Manuf Technol 35(9):895–899

Maciulevičius M et al (2011) Evaluation of Laser Drilling of Ni Film on Silicon for Solid Oxide Fuel Cells. Phys Procedia 12:317–322

Tokarev VN et al (2003) High-aspect-ratio microdrilling of polymers with UV laser ablation: experiment with analytical model. Applied Physics A 76(3):385–396

Lazare S, Tokarev V (2004) Recent experimental and theoretical advances in microdrilling of polymers with ultraviolet laser beams. in Fifth International Symposium on Laser Precision Microfabrication. SPIE.

Wu C-Y, Shu C-W, Yeh Z-C (2006) Effects of excimer laser illumination on microdrilling into an oblique polymer surface. Opt Lasers Eng 44(8):842–857

Masmiati N, Philip PK (2007) Investigations on laser percussion drilling of some thermoplastic polymers. J Mater Process Technol 185(1):198–203

Amalina NS et al (2017) Prediction Modelling of Recast Layer and Circularity for Laser Drilling of Polyethylene Terephthalate (PETG) Thermoplastic. Procedia Eng 184:197–204

Masamori E et al (2016) Anomalous enhancement of drilling rate in carbon fiber reinforced plastic using azimuthally polarized CO 2 laser. Laser Phys 26(9):096001

Salama A et al (2016) High-power picosecond laser drilling/machining of carbon fibre-reinforced polymer (CFRP) composites. Applied Physics A 122(2):73

Zang Z, Zeng X, Du J et al (2016) Femtosecond laser direct writing of microholes on roughened ZnO for output power enhancement of InGaN light-emitting diodes[J]. Opt Lett 41(15):3463–3466

Lishi Jiao, Hongyu Zheng, Yilei Zhang, Eddie Yin Kwee Ng (2019) “picosecond laser drilling of silicon with applied voltage”, Springer Nature (SN) Applied Science (SNAS) 1(1), 80

Luzius S et al (2013) PCB Drilling with High Power Picosecond Lasers. Phys Procedia 41:723–726

He C et al (2014) High-precision Helical Cutting Using Ultra-short Laser Pulses. Phys Procedia 56:1066–1072

He C, Bühring J, Gillner A (2018) Helical drilling of three-dimensional conical converging-diverging nozzle in steel using ultrashort laser pulses. Procedia CIRP 74:305–309

Jiao L et al (2018) Picosecond laser drilling of silicon with applied voltage. SN Applied Sciences 1(1):80

Straub M, Ventura M, Gu M (2004) Microvoid channel polymer photonic crystals with large infrared stop gaps and a multitude of higher-order bandgaps fabricated by femtosecond laser drilling in solid resin. Thin Solid Films 453-454:522–526

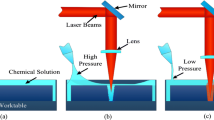

Jiao LS et al (2011) The effect of assist liquid on the hole taper improvement in femtosecond laser percussion drilling. Phys Procedia 19:426–430

Kaakkunen JJJ et al (2011) Water-Assisted Femtosecond Laser Pulse Ablation of High Aspect Ratio Holes. Phys Procedia 12:89–93

Romoli L et al (2015) Microstructural Changes Induced by Ultrashort Pulsed Lasers in Microdrilling of Fuel Nozzles. Procedia CIRP 33:508–513

Gruner A, Schille J, Loeschner U (2016) Experimental Study on Micro Hole Drilling Using Ultrashort Pulse Laser Radiation. Phys Procedia 83:157–166

Casalino G et al (2017) Statistical Analysis and Modelling of an Yb: KGW Femtosecond Laser Micro-drilling Process. Procedia CIRP 62:275–280

Ito Y et al (2018) Mechanisms of damage formation in glass in the process of femtosecond laser drilling. Applied Physics A 124(2):181

Béranger AS et al (2018) Fatigue crack growth behavior of NBR, HNBR. HNBR ZSC compounds Procedia Engineering 213:145–152

Eyssa HM et al (2018) Mechanical and physical properties of nanosilica/nitrile butadiene rubber composites cured by gamma irradiation. Egypt J Pet 27(3):383–392

Liu X et al (2015) Volatile components changes during thermal aging of nitrile rubber by flash evaporation of Py-GC/MS. J Anal Appl Pyrolysis 113:193–201

Liu J et al (2016) Investigation of aging behavior and mechanism of nitrile-butadiene rubber (NBR) in the accelerated thermal aging environment. Polym Test 54:59–66

Pinedo B et al (2018) Thermal analysis and tribological investigation on TPU and NBR elastomers applied to sealing applications. Tribol Int 127:24–36

Farajollahi M et al (2016) Self-contained tubular bending actuator driven by conductingpolymersMeisam. Sensors Actuators A Phys 249:45–56

Döring S et al (2013) Hole Formation Process in Ultrashort Pulse Laser Percussion Drilling. Phys Procedia 41:431–440

Funding

Financial support was given under the Taishan Scholar scheme of Shandong province.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 278 kb)

Rights and permissions

About this article

Cite this article

Hernandez-Castaneda, J.C., Lim, H., Wan, Y. et al. An experimental investigation of laser drilling nitrile butadine (NBR) rubber. Int J Adv Manuf Technol 108, 1139–1152 (2020). https://doi.org/10.1007/s00170-019-04622-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04622-0