Abstract

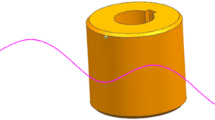

Scroll compressors have been widely used in refrigeration and air conditioners. The manufacturing of scroll components with complex shape and of high precision constitutes a very important task in guaranteeing the performance of a scroll compressor. Uniform scrolls with constant wrap thickness may be availably machined by generating method. However, for the machining of non-uniform scrolls with variable wrap thickness, the generating method is no longer applicable. The current practice in the machining of non-uniform scrolls is to apply a numerical method using CAD/CAM software in a CNC milling machine. This process is data-intensive and the machining quality is not reliable as the tool path generated does not have G1 continuity. In this paper, the authors present a double circular arc (DCA) fitting algorithm for high-precision manufacturing of non-uniform scroll components. The proposed algorithm is validated by cutting experiments on a CNC milling machine, which incorporates the DCA fitting algorithm–based finishing machining and NC tool path code generation. Test results have shown that the application of DCA fitting algorithm to non-uniform scroll machining is effective, not only in decreasing the number of generated tool path points, but also with satisfied machining precision.

Similar content being viewed by others

References

Morishita E, Sugihara M (1986) Some design problems of scroll compressors. Bull JSME 29(258):4139–4146

Ivlev VI, Bozrov VM, Voronov VA (2015) Testing a scroll machine in pneumatic motor-expander modes. J Machin Manuf Reliabil 44(2):120–124. https://doi.org/10.3103/S1052618815020053

Cui MM (2006) Numerical study of unsteady flows in a scroll compressor. J Fluids Eng 128(5):947–955. https://doi.org/10.1115/1.2243300

Winandy EO, Saavedra C, Jean L (2002) Experimental analysis and simplified modeling of a hermetic scroll refrigeration compressor. Appl Therm Eng 22:107–120. https://doi.org/10.1016/S1359-4311(01)00083-7

Dong AC, Oh KK, Myung DO (2014) An experimental study on semiconductor process chiller using the digital scroll compressor. J Mech Sci Technol 28(8):3345–3352. https://doi.org/10.1007/s12206-014-0745-7

Blunier B, Cirrincione G, Herve Y, Miraoui A (2008) A new analytical and dynamical model of a scroll compressor with experimental validation. Int J Refrig 32(5):874–891. https://doi.org/10.1016/j.ijrefrig.2008.11.009

Wang H, Tian J, Du Y, Hou X (2018) Numerical simulation of CO2 scroll compressor in transcritical compression cycle. Heat Mass Transfer 54:1395–1403. https://doi.org/10.1007/s00231-017-2239-5

Sun H, Hu H, Wu J, Ding G, Li G (2018) A theory-based explicit calculation model for variable speed scroll compressors with vapor injection. Int J Refrig 188:402–412. https://doi.org/10.1016/j.ijrefrig.2018.01.016

Wang BL, Han LJ, Shi WX, Li XT (2012) Modulation method of scroll compressor based on suction gas bypass. Appl Therm Eng 37:183–189. https://doi.org/10.1016/j.applthermaleng.2011.11.014

Kim D, Jeon Y, Jang D (2018) Performance comparison among two-phase liquid and vapor injection heat pumps with a scroll compressor using R410A. Appl Therm Eng 137:193–202. https://doi.org/10.1016/j.applthermaleng.2018.03.086

Rak J, Pietrowicz S, Gnutek Z (2017) 3D numerical calculations of tangent leakages in scroll compressor during unsteady process. Prog Comput Fluid Dyn 17(6):344–351. https://doi.org/10.1504/PCFD.2017.10007945

Kato K, Takeuchi Y, Maeda Y, Yamanaka T (2005) High-precision and high-efficiency machining of scroll compressor components bottom machining of orbiting and fixed scrolls in low wear. Int J Adv Manuf Technol 27(3–4):260–267. https://doi.org/10.1007/s00170-004-2176-6

Bell IH, Groll EA, Braun JE, Horton WT, Lemort V (2014) Comprehensive analytic solutions for the geometry of symmetric constant-wall-thickness scroll machines. Int J Refrig 45:223–242. https://doi.org/10.1016/j.ijrefrig.2014.05.029

Peng B, Lemort V, Legros A, Zhang HS (2017) Variable thickness scroll compressor performance analysis-Part I: geometric and thermodynamic modeling. Proc Inst Mech Eng, Part E 231(4):633–640. https://doi.org/10.1177/0954408916640418

Liu Y, Tang Y, Chang Y, Yang Y (2012) Optimum design of scroll profiles created from involute of circle with variable radii by using finite element analysis. Mech Mach Theory 55:1–17. https://doi.org/10.1016/j.mechmachtheory.2012.04.002

Wang XR, Wang ZQ, Wang YS, Lin TS, He P (2017) A bisection method for the milling of NURBS mapping projection curves by CNC machines. Int J Adv Manuf Technol 91(1–4):155–164. https://doi.org/10.1007/s00170-016-9569-1

Chen Y, Yao L (2018) Study on a method of CNC form milling for the concave convex arc line gear. Int J Adv Manuf Technol 99(9–12):2327–2339. https://doi.org/10.1007/s00170-018-2566-9

Sprott K (2016) Surface normal interpolation for five axis CNC milling. Int J Adv Manuf Technol 84(9–12):2319–2329. https://doi.org/10.1007/s00170-015-7790-y

Pi SW, Liu Q, Liu QT (2018) A novel dynamic contour error estimation and control in high-speed CNC. Int J Adv Manuf Technol 96(1–4):547–560. https://doi.org/10.1007/s00170-018-1629-2

Jiang Z, Cheng K, Harrison DK (2000) A concurrent engineering approach to the development of a scroll compressor. J Mater Process Technol 107:194–200. https://doi.org/10.1016/S0924-0136(00)00723-8

Jiang Z, Harrison DK, Cheng K (2003) Computer-aided design and manufacturing of scroll compressors. J Mater Process Technol 138:145–151. https://doi.org/10.1016/S0924-0136(03)00063-3

Meek DS, Walton DJ (1995) Approximating smooth planar curves by arc splines. J Comput Appl Math 59(2):221–231. https://doi.org/10.1016/0377-0427(94)00029-Z

Šír Z, Feichtinger R, Jüttler B (2006) Approximating curves and their offsets using biarcs and Pythagorean hodograph quintics. Comput Aided Des 38(6):608–618. https://doi.org/10.1016/j.cad.2006.02.003

Yang J, Wu A, Liu Y (2018) Kinematics model and trajectory interpolation algorithm for CNC turning of non-circular profiles. Precis Eng. 54:212–221. https://doi.org/10.1016/j.precisioneng.2018.05.014

Knez M, Žagar E (2018) Interpolation of circular arcs by parametric polynomials of maximal geometric smoothness. Comput Aided Geom Des 63:66–77. https://doi.org/10.1016/j.cagd.2018.05.002

Chen H, Zhao WS, Xi XC, Chen M (2017) Non-circular parametric curve and curved surface interpolation and tool compensation for WEDM based on unit arc length increment method. Int J Adv Manuf Technol 88(5–8):1257–1266. https://doi.org/10.1007/s00170-016-8851-6

Lee JN, Li CN (2010) The CAM system for scroll profile with three CNC interpolations. Adv Mater Res 83–86:696–703. https://doi.org/10.4028/www.scientific.net/AMR.83-86.696

Qiu H, Kubo A, Li ZY, Lin C (2008) Optimal Archimedes’ spiral interpolation for cutter path generation in NC machining of noncircular contours. Int J Adv Manuf Technol 36(1–2):69–82. https://doi.org/10.1007/s00170-006-0809-7

Funding

This study is supported by the National Natural Science Foundation of China (Grant No. 51665035) and the fundamental research funds for the universities in Gansu Province (Grant No. 1302ZTC034).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, Z., Liu, T. A double circular arc fitting algorithm for CNC machining of non-uniform scroll components. Int J Adv Manuf Technol 104, 4485–4495 (2019). https://doi.org/10.1007/s00170-019-04304-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04304-x