Abstract

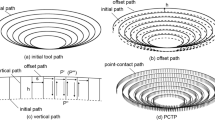

For the manufacturing of large-scale sheet parts, traditional stamping, spinning, and single-point incremental forming are limited by the rupture prone and severe springback of the formed parts and the requirement of large-scale forming equipment. In this paper, the method of electromagnetic incremental forming (EMIF) based on dual coil was creatively proposed to solve the manufacturing problem of large-scale parts of aluminum alloy. The forming results of EMIF based on single coil and EMIF based on dual coil are compared by finite element simulation. The effect of the two moving strategies on uniformity in EMIF based on dual coil was researched. In addition, the effect of the shaping voltage on uniformity in EMIF based on dual coil with the interval moving strategy was studied. It was observed that the forming quality of EMIF with dual coil was better than that of EMIF with single coil. For EMIF based on dual coil, the interval moving strategy is better than the sequential moving strategy in achieving better forming quality. For the first layer of EMIF based on dual coil with the interval moving strategy, the optimized forming voltage and shaping voltage were 12 kV and 18 kV, respectively. For the second layer of EMIF based on dual coil with interval moving strategy, the optimized forming voltage and shaping voltage were 18 kV and 27 kV, respectively. The shaping voltage was 1.5 times of forming voltage for both layers so that better forming uniformity was achieved. Then, the method of EMIF based on dual coil with interval moving strategy by multilayers is proposed to fabricate large-scale sheet parts. Finally, experiments were performed to confirm the feasibility of EMIF with dual coil, and the experiment results show good agreement with the simulation results. The findings of this work could provide guidance on deform large-scale parts of aluminum alloy by the EMIF method.

Similar content being viewed by others

References

Psyk V, Risch D, Kinsey BL, Tekkaya AE, Kleiner M (2011) Electromagnetic forming—a review. J Mater Process Technol 211(5):787–829. https://doi.org/10.1016/j.jmatprotec.2010.12.012

Li FQ, Mo JH, Li JJ, Zhao J (2017) Formability evaluation for low conductive sheet metal by novel specimen design in electromagnetic forming. Int J Adv Manuf Technol 88(5–8):1677–1685. https://doi.org/10.1007/s00170-016-8893-9

Zhu H, Huang L, Li JJ, Li XX, Ma HJ, Wang CM, Ma F (2018) Strengthening mechanism in laser-welded 2219 aluminium alloy under the cooperative effects of aging treatment and pulsed electromagnetic loadings. Mater Sci Eng A 714:124–139. https://doi.org/10.1016/j.msea.2017.12.081

Imbert JM, Winkler SL, Worswick MJ, Oliveira DA, Golovashchenko S (2005) The effect of tool–sheet interaction on damage evolution in electromagnetic forming of aluminium alloy sheet. Trans asme J eng mater technol 127(1):145–153. https://doi.org/10.1115/1.1839212

Iriondo E, Gutiérrez MA, González B, Alcaraz JL, Daehn GS (2011) Electromagnetic impulse calibration of high strength sheet metal structures. J Mater Process Technol 211(5):909–915. https://doi.org/10.1016/j.jmatprotec.2010.05.013

Cui XH, Yu HL, Wang QS (2018) Electromagnetic impulse calibration in V-shaped parts. Int J Adv Manuf Technol 97(5–8):2959–2968. https://doi.org/10.1007/s00170-018-2108-5

Li JJ, Qiu W, Huang L, Su HL, Tao H, Li PY (2018) Gradient electromagnetic forming (GEMF): a new forming approach for variable-diameter tubes by use of sectional coil. Int J Mach Tools Manuf 135:65–77. https://doi.org/10.1016/j.ijmachtools.2018.08.005

Okoye CN, Jiang JH, Hu ZD (2006) Application of electromagnetic-assisted stamping (EMAS) technique in incremental sheet metal forming. Int J Mach Tools Manuf 46(11):1248–1252. https://doi.org/10.1016/j.ijmachtools.2006.01.029

Ma HJ, Huang L, Li JJ, Duan XC, Ma F (2018) Effects of process parameters on electromagnetic sheet free forming of aluminium alloy. Int J Adv Manuf Technol 96(1–4):359–369. https://doi.org/10.1007/s00170-018-1589-6

Oliveira DA, Worswick MJ, Finn M, Newman D (2005) Electromagnetic forming of aluminium alloy sheet: free-form and cavity fill experiments and model. J Mater Process Technol 170(1):350–362. https://doi.org/10.1016/j.jmatprotec.2005.04.118

Xiong WR, Wang WP, Wan M, Li XJ (2015) Geometric issues in V-bending electromagnetic forming process of 2024-T3 aluminium alloy. J Manuf Process 19:171–182. https://doi.org/10.1016/j.jmapro.2015.06.015

Kamal M, Shang J, Cheng V, Hatkevich S, Daehn GS (2007) Agile manufacturing of a micro-embossed case by a two-step electromagnetic forming process. J Mater Process Technol 190(1):41–50. https://doi.org/10.1016/j.jmatprotec.2007.03.114

Su HL, Huang L, Li JJ, Ma F, Huang P, Feng F (2018) Two-step electromagnetic forming: A new forming approach to local features of large-size sheet metal parts. Int J Mach Tools Manuf 124:99–116. https://doi.org/10.1016/j.ijmachtools.2017.10.005

Daehn G, Vohnout VJ 2000 Hybrid methods of metal forming using electromagnetic forming. US6050121A

Vohnout VJ (1999) A hybrid quasi-static/dynamic process for forming large sheet metal parts from aluminium alloys. Dissertation, The Ohio State University

Shang J, Daehn G (2011) Electromagnetically assisted sheet metal stamping. J Mater Process Technol 211(5):868–874. https://doi.org/10.1016/j.jmatprotec.2010.03.005

Shang J (2006) Electromagnetically assisted sheet metal stamping. Dissertation, The Ohio State University

Woodward S, Weddeling C, Daehn GS, Psyk V, Carson B, Tekkaya A (2010) Agile production of sheet metal aviation components using disposable electromagnetic actuators. In: 4th International Conference on High Speed Forming-ICHSF2010 OAI 35–46. https://doi.org/10.17877/DE290R-8744

Luo W, Huang L, Li J, Liu X, Wang Z (2014) A novel multi-layer coil for a large and thick-walled component by electromagnetic forming. J Mater Process Technol 214(11):2811–2819. https://doi.org/10.1016/j.jmatprotec.2014.05.023

Golovashchenko SF (2007) Material formability and coil design in electromagnetic forming. J Mater Eng Perform 16(3):314–320. https://doi.org/10.1007/s11665-007-9058-7

Cui XH, Li JJ, Mo JH, Fang JX, Zhu YT, Zhong K (2015) Investigation of large sheet deformation process in electromagnetic incremental forming. Mater Des 76:86–96. https://doi.org/10.1016/j.matdes.2015.03.060

Guo K, Lei XP, Zhan M, Tan JQ (2017) Electromagnetic incremental forming of integral panel under different discharge conditions. J Manuf Process 28:373–382. https://doi.org/10.1016/j.jmapro.2017.01.010

Wang ZQ (2015) Study on electromagnetic incremental forming process of large aluminium alloy curved surface parts. Dissertation, Huazhong University of Science and Technology (In Chinese)

Yan SL, Li HW, Li P, Xue KW (2018) Mechanisms and forming rules of large thin-walled aluminium alloy components in electromagnetic incremental forming. Procedia Manuf 15:1306–1313

Li HW, Yao X, Yan SL, He J, Zhan M, Huang L (2018) Analysis of forming defects in electromagnetic incremental forming of a large-size thin-walled ellipsoid surface part of aluminium alloy. J Mater Process Technol 255:703–715. https://doi.org/10.1016/j.jmatprotec.2018.01.024

Zhang QX, Huang L, Li JJ, Feng F, Su HL, Ma F, Zhong K (2019) Investigation of dynamic deformation behaviour of large-size sheet metal parts under local Lorentz force. J Mater Process Technol 265:20–33. https://doi.org/10.1016/j.jmatprotec.2018.09.036

Liu XL, Huang L, Su HL, Ma F, Li JJ (2018) Comparative research on the rebound effect in direct electromagnetic forming and indirect electromagnetic forming with an elastic medium. Materials 11(8):1450. https://doi.org/10.3390/ma11081450

Fang JX, Mo JH, Li JJ, Zhou B (2017) Feasibility of electromagnetic pulse-assisted incremental drawing with a radial magnetic force for AA-5052 aluminum alloy sheet. Int J Adv Manuf Technol 88:3123–3137. https://doi.org/10.1007/s00170-016-9025-2

Funding

This work was financially supported by the National Natural Science Foundation of China (51575206 and 51435007), the Innovation Funds for Aerospace Science and Technology from the China Aerospace Science and Technology Corporation (CASC150704), the Science Fund of State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body (31615006), and the Fundamental Research Funds for the Central University (2016YXZD055).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, X., Huang, L., Li, J. et al. An electromagnetic incremental forming (EMIF) strategy for large-scale parts of aluminum alloy based on dual coil. Int J Adv Manuf Technol 104, 411–431 (2019). https://doi.org/10.1007/s00170-019-03892-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03892-y