Abstract

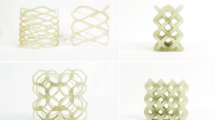

Stereolithography (SLA)-based three-dimensional (3D) printing is widely used in both industrial and consumer markets for prototyping and concept validation. It also plays an important role in aircraft industry as it offers advantages in surface finish and high precision. Despite the extensive usage, the combination of large volume, high resolution, and high speed is hard to achieve. This paper presents a 3D printing technology that allows a UV projector to continuously cure resin while scanning over the build area. To print large objects, 3D models are sliced into layer-by-layer, high-resolution image “maps”. Each “map” is further divided into sub-region images that are dynamically exposed to the photocurable materials and synchronized with the scanning of the projector, causing a still exposure pattern to appear on the build area. Therefore, large objects with delicate details can be printed layer-by-layer. As such, customized build volumes on a large scale (greater than 1 m3) can be achieved with micro-scale features. Along with a wiping system, this technique is compatible with various materials, leading to the direct manufacturing of final parts from photocurable materials. Furthermore, this technique shows advantages over existing large-scale DLP printing methods regarding both printing speed and material flexural properties. This technique can be implemented at design workflow in the aerospacing industry by facilitating design communication, validation, pre-production, and even assisting in producing final parts.

Similar content being viewed by others

References

Giannopoulos AA, Mitsouras D, Yoo SJ, Liu PP, Chatzizisis YS, Rybicki FJ (2016) Applications of 3D printing in cardiovascular diseases. Nat Rev Cardiol 13:701–718

Stansbury JW, Idacavage MJ (2016) 3D printing with polymers: challenges among expanding options and opportunities. Dent Mater 32:54–64

Cooper F (2016) Sintering and additive manufacturing: ‘additive manufacturing and the new paradigm for the jewellery manufacturer. Prog Addit Manuf 1:29–43

Lu B, Li D, Tian X (2015) Development trends in additive manufacturing and 3D printing. Engineering 1:85–89

Crump SS (1992) Apparatus and method for creating three-dimensional objects. US pat. 5,121, vol 329, p 15

Hull CW (1986) Apparatus for production of three-dimensional objects by stereolithography. US Pat. 4,575,330 1–16. https://doi.org/10.1145/634067.634234

Chen X et al (2018) High-speed 3D printing of millimeter-size customized aspheric imaging lenses with sub 7 nm surface roughness. Adv Mater 30:1705683

Barnett E, Gosselin C (2015) Large-scale 3D printing with a cable-suspended robot. Addit Manuf 7:27–44

Pawar AA, Saada G, Cooperstein I, Larush L, Jackman JA, Tabaei SR, Cho NJ, Magdassi S (2016) High-performance 3D printing of hydrogels by water-dispersible photoinitiator nanoparticles. Sci Adv 2:e1501381

Yunus DE, Sohrabi S, He R, Shi W, Liu Y (2017) Acoustic patterning for 3D embedded electrically conductive wire in stereolithography. J Micromech Microeng 27:45016

Song X, Chen Y, Lee TW, Wu S, Cheng L (2015) Ceramic fabrication using mask-image-projection-based Stereolithography integrated with tape-casting. J Manuf Process 20:456–464

He R, Yunus D, Uhl C, Shi W, Sohrabi S, Liu Y (2017) Fabrication of circular microfluidic channels through grayscale dual-projection lithography. Microfluid Nanofluidic 21:13

Melchels FPW, Feijen J, Grijpma DW (2010) A review on stereolithography and its applications in biomedical engineering. Biomaterials 31:6121–6130

Zhang AP, Qu X, Soman P, Hribar KC, Lee JW, Chen S, He S (2012) Rapid fabrication of complex 3D extracellular microenvironments by dynamic optical projection stereolithography. Adv Mater 24:4266–4270

He R, Wang S, Andrews G, Shi W, Liu Y (2016) Generation of customizable micro-wavy pattern through grayscale direct image lithography. Sci Rep 6:21621

Lu Y, Mapili G, Suhali G, Chen S, Roy K (2006) A digital micro-mirror device-based system for the microfabrication of complex, spatially patterned tissue engineering scaffolds. J Biomed Mater Res A 77:396–405

Tumbleston JR et al (2015) Continuous liquid interface production of 3D objects. Science. 347:1349 LP–1341352

Lee MP, Cooper GJT, Hinkley T, Gibson GM, Padgett MJ, Cronin L (2015) Development of a 3D printer using scanning projection stereolithography. Sci Rep 5:9875

Acknowledgements

The authors would like to thank Steven Lee for research assistance.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

He, R., Landowne, J., Currie, J. et al. Three-dimensional printing of large objects with high resolution by scanning lithography. Int J Adv Manuf Technol 105, 4147–4157 (2019). https://doi.org/10.1007/s00170-019-03862-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03862-4