Abstract

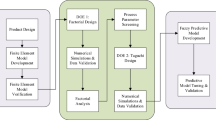

In production of the polymeric parts, injection molding is an important processing technique which provides easy automation and economic manufacturing. Since several parameters indicate crucial influences on this method, artificial intelligence (AI) approaches have been utilized to optimize the injection molding process. In this study, an intelligent system is implemented to detect different faults in injection molding. To this aim, we used the fuzzy case-based reasoning (fuzzy CBR) approach as a complementary reasoning method in AI. CBR solves new problems via referring to the nearest solutions of the most similar cases. Problems in which attribute values have fuzzy characteristics are fuzzified and similarity measurements developed with respect to these features. Using fuzzy logic in the retrieval phase of our CBR system leads to easier transfer of knowledge across domains. In the current research, the triangular fuzzy numbers are utilized to represent the imprecise numerical quantities in the relationship values of each feature and related parameters based on domain experts’ knowledge. An implemented system is evaluated by detection of various faults in a production line. The obtained results proved capability and accuracy of the proposed system in detection of faults. The system is much faster than traditional method and indicates a stable product quality. The proposed system can also be adapted for other complex products in the injection molding process.

Similar content being viewed by others

References

Celano G, Fichera S, Fratini L, Micari F (2001) The application of AI techniques in the optimal design of multi-pass cold drawing processes. J Mater Process Technol 113:680–685

Choudhury N, Begum SA (2017) Case-based reasoning : a survey. Indian J Comput Sci Eng 8:333–340

Choy KL, Lee WB, Lo V (2003) Design of an intelligent supplier relationship management system: a hybrid case based neural network approach. Expert Syst Appl 24:225–237

Choy KL, Lee WB, Lau HCW, Choy LC (2005) A knowledge-based supplier intelligence retrieval system for outsource manufacturing. Knowl-Bases Syst 18:1–17

Cover T, Hart P (1967) Nearest neighbor pattern classification. IEEE Trans Inf Theor 13:21–27

Evans RG, Sadler EJ (2008) Methods and technologies to improve efficiency of water use. Water Resour Res 44:1–15

Farhan U, Tolouei-Rad M, Osseiran A (2017) Indexing and retrieval using case-based reasoning in special purpose machine designs. Int J Adv Manuf Technol 92(5):2689–2703

Hashemi H, Shaharoun AM, Sudin I (2014) A case-based reasoning approach for design of machining fixture. Int J Adv Manuf Technol 74(1):113–124

Hechenbichler K, Schliep K (2004) Weighted k-Nearest-Neighbor Techniques and Ordinal Classification. Discussion Paper 399. Ludwig Maximilians University, Munich

Huang S, Tan K, Lee T (2004) Neural-network-based predictive learning control of ram velocity in injection molding. IEEE Trans Syst Man Cybern C Appl Rev 34:363–368

Jeng BC, Liang TP (1995) Fuzzy indexing and retrieval in case-based systems. Expert Syst Appl 8:135–142

Jin X, Zhu X (2000) Process parametrs’ setting using case-based and fuzzy reasoning for injection molding. In: Proceedings of the World Cong Intell Control Autom, pp 335–340

Kerkstra R, Brammer S (2018) Injection Molding Advanced Troubleshooting Guide. Carl Hanser Verlag GmbH & Co., Munich

Khosravani MR, Nasiri S, Anders D, Weinberg K (2019) Prediction of dynamic properties of ultra-high performance concrete by an artificial intelligence approach. Adv Eng Sofw 127:51–58

Khosravani MR, Nasiri S, Weinberg K (2019) Application of case-based reasoning in a fault detection system on production of drippers. Appl Soft Comput, pp 227–232

Kwong C (2001) A case-based system for process design of injection moulding. Int J Comput Appl Technol 14:40–50

Kwong C, Smith G, Lau W (1997) Application of case based reasoning in injection moulding. J Mater Process Technol 63:463– 467

Kwong CK, Smith GF (1998) A computational system for process design of injection moulding: combining blackboard-based expert system and case-based reasoning approach. Int J Adv Manuf Technol 14:239–246

Li C, Wang F, Chang Y, Liu Y (2010) A modified global optimization method based on surrogate model and its application in packing profile optimization of injection molding process. Int J Adv Manuf Technol 48:505–511

Liao TW (2004) An investigation of a hybrid CBR method for failure mechanisms identification. Eng Appl Artif Intell 17:123–134

Liao TW, Kuo RJ (2018) Five discrete symbiotic organisms search algorithms for simultaneous optimization of feature subset and neighborhood size of knn classification models. Appl Soft Comput 64:581–595

Malek M, Toitgans M-P, Wybo J-L, Vincent M (1998) An operator support system based on case-based reasoning for the plastic moulding injection process. Lecture Notes in Artificial Intelligence 1448:402–413

Manjunath P, Krishna P (2012) Prediction and optimization of dimensional shrinkage variations in injection molded parts using forward and reverse mapping of artificial neural networks. Adv Mater Res 463:674–678

Mathivanan D, Nouby M, Vidhya R (2010) Minimization of sink mark defects in injection molding process. Int J Eng Sci Technol 2:13–22

Mei Y, Shan Z (2008) The optimization of plastic injection molding process based on support vector machine and genetic algorithm. In: Proceedings of the Int Conf Intell Comput Technol Autom, pp 1258–1261

Mok S, Kwong C (2002) Application of artificial neural network and fuzzy logic in a case-based system for initial process parameter setting of injection molding. J Intell Manuf 13:165–176

Nasiri S, Khosravani MR, Weinberg K (2017) Fracture mechanics and mechanical fault detection by artificial intelligence methods: a review. Eng Fail Anal 81:270–293

Neufville RD, Clark J, Field FR (2016) Introduction to technical cost modeling concepts and illustrations. In: Material Systems Laboratory, MIT, pp 1–34

Opricovic S, Fuzzy VIKOR (2011) With an application to water resources planning. Expert Syst Appl 38:12983–12990

Pham DT, Pham PTN (1999) Artificial intelligence in engineering. Int J Mach Tool Manufact 39:937–949

Pinyol I, Ventura R, Cabanillas D (2012) A case-based hybrid system for injection molding sensorization. Artif Intell Res Dev 248:203–212

Richter MM, Weber R (2013) Case-Based Reasoning a Textbook. Springer, Berlin

Rosato DV, Rosato D, Rosato MG (2000) Injection Molding Handbook. Springer Science & Business Media, Berlin

Sadeghi B (2000) A BP-neural network predictor model for plastic injection molding process. J Mater Process Technol 103:411–416

Shelesh-Nezhad K, Siores E (1997) An intelligent system for plastic injection molding process design. J Mater Process Technol 63:458–462

Shen C, Wang L, Li Q (2007) Optimization of injection molding process parameters using combination of artificial neural network and genetic algorithm method. J Mater Process Technol 118:412–418

Shi F, Lou Z, Lu J, Zhang Y (2003) Optimization of plastic injection moulding process with soft computing. Int J Adv Manuf Technol 21:665–661

SP&F (2017) Semnan Polyethylene Pipe and Fitting Co. http://www.semnanpe.com/en/

Stahl A, Roth-Berghofer T (2008) Rapid prototyping of CBR applications with the open source tool myCBR. In: Proceedings of the 9th European Conference on Advances in Case-based Reasoning, Heidelberg, pp 615–629

Sun SH, Chen JL (1995) A modular fixture design system based on case-based reasoning. Int J Adv Manuf Technol 10(6):389– 395

Tan K, Huang S, Jiang X (2001) Adaptive control of ram velocity for the injection moulding machine. IEEE Trans Control Syst Technol 9:663–671

Tsai Y-T (2009) Applying a case-based reasoning method for fault diagnosis during maintenance. IMechE Part C: J Mech Eng Sci 223:2431–2441

Tsoi HP, Gao F (1999) Control of injection velocity using a fuzzy logic rule-based contyrololer for thermoplastic injection molding. Polym Eng Sci 39:3–17

Vasudevau C, Smith SM, Ganesan K (1994) Fuzzy logic in case-based reasoning. In: The First International Joint Conference of the North American Fuzzy Information Processing Society Biannual Conference, pp 301–302

Wang H, Wang Y, Wang Y (2013) Cost estimation of plastic injection molding parts through integration of PSO and BP neural network. Expert Syst Appl 40:418–428

Wang W, Song Z, Han B, Li P (2000) A fault diagnosis expert system for hydraulic system of injection moulding. Proceedings of the World Congress on Intelligent Control and Automation 1:229–232

Wu M, Lo Y, Hsu S (2008) A fuzzy cbr technique for generating product ideas. Expert Syst Appl 34:530–540

Xian G (2010) Mechanical failure classification for spherical roller bearing of hydraulic injection molding machine using DWT–SVM. Expert Syst Appl 37:6742–6747

Yang S, Bian C, Li X, Tan L, Tang D (Feb 2018) Optimized fault diagnosis based on fmea-style cbr and bn for embedded software system. Int J Adv Manuf Technol 94(9):3441–3453

Yang Y, Gao F (1991) Cycle-to-cycle within-cycle adaptive control of nozzle pressure during packing-holding of thermoplastic injection molding. J Polymer Eng Sci 39:2042–2063

Yarlagadda P (2002) Development of an integrated neural network system for prediction of process parameters in metal injection moulding. J Mater Process Technol 130:315–320

Yarlagadda P, Khong C (2001) Development of a hybrid neural network system for prediction of process parameters in injection moulding. J Mater Process Technol 118:109–115

Yin F, Mao H, Hua L, Guo W, Shu M (2011) Back propagation neural network modeling for warpage prediction and optimization of plastic products during injection molding. Mater Des 32:1844–1850

Zhai M, Lam Y, Au C (2009) Runner sizing in multiple cavity injection mould by non-dominated sorting genetic algorithm. Eng Comput 25:237–245

Zhang J, Alexander S (2008) Fault diagnosis in injection moulding via cavity pressure. Int J Prod Res 1:6499–6512

Zhang W, van Luttervelt C (2011) Toward a resilient manufacturing system. CIRP Ann Manuf Technol 60(1):469–472

Zhengying W, Yiping T, Bingheng L (2003) A rapid manufacturing method for water-saving emitters for crop irrigation based on rapid prototyping and manufacturing. Int J Adv Manuf Technol 21:644–648

Acknowledgements

We are grateful to Mr. Farhad Sadaghiani chairman of Semnan Polyet hylene Pipe and Fitting company, who provided data on drippers production line. This research is performed according to the irrigation tape lines (NOVA Drip) which have been produced in SP&F.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nasiri, S., Khosravani, M.R. Faults and failures prediction in injection molding process. Int J Adv Manuf Technol 103, 2469–2484 (2019). https://doi.org/10.1007/s00170-019-03699-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03699-x