Abstract

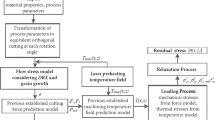

In current study, an inverse analysis is conducted on tool life based on five process parameters, by predicting tool life based on guessed process parameters, which is defined as the forward problem, and applying iterative gradient search to find process parameters for next iteration, which is defined as the inverse problem. For forward problem, the effect of laser beam is included by treating it as a heat source on top surface. Next, the milling configuration is simplified as orthogonal cutting followed by angular-dependent coordinate transformation at each rotation angle. The effective force due to flank wear is predicted by integrating the stress components along the chip cross section and wear land, and the average stress on tool-workpiece interface is then derived based on the effective force and contact area. The average temperature along the interface is derived by considering secondary and rubbing heat sources. The stress and temperature affects the abrasion, adhesion, and diffusion which determine the flank wear rate. The tool life is then decided as the cutting time when the flank wear limit of the tool is reached. The iterative gradient search or variance-based recursive method is applied to solve inverse problem and update process parameters to match the tool life. Three cutting parameters including depth of cut, feed per tooth, and cutting speed, and two laser parameters including laser-tool distance and laser power are updated in each iteration. The proposed model is validated through experimental measurements on the laser-assisted milling of K24 nickel-based superalloy. The proposed predictive model is able to match the measured tool life with high computation efficiency less than 540 s and high accuracy of less than 7% difference.

Similar content being viewed by others

References

Huang Y (2002) Predictive modeling of tool wear rate with application to cbn hard turning, in Mechanical Engineering, Georgia Institute of Technology. p. 245

Zhang G, Guo C (2016) Modeling flank wear progression based on cutting force and energy prediction in turning process. Procedia Manuf 5:536–545

Huang Y, Liang SY (2004) Modeling of CBN tool flank wear progression in finish hard turning. J Manuf Sci Eng 126(1):98

Huang Y, Chou YK, Liang SY (2007) CBN tool wear in hard turning: a survey on research progresses. Int J Adv Manuf Technol 35(5–6):443–453

Pan Z, Feng Y, Hung TP, Jiang YC, Hsu FC, Wu LT, Lin CF, Lu YC, Liang SY (2017) Heat affected zone in the laser-assisted milling of Inconel 718. J Manuf Process 30:141–147

Pan Z, Feng Y, Liang SY (2017) Material microstructure affected machining: a review. Manufacturing Rev 4:5

Pan Z, Feng Y, Lu YT, Lin YF, Hung TP, Hsu FC, Lin CF, Lu YC, Liang SY (2017) Microstructure-sensitive flow stress modeling for force prediction in laser assisted milling of Inconel 718. Manufacturing Rev 4:6

Feng Y, Lu YT, Lin YF, Hung TP, Hsu FC, Lin CF, Lu YC, Liang SY (2018) Inverse analysis of the cutting force in laser-assisted milling on Inconel 718. Int J Adv Manuf Technol 96(1):905–914

Pan Z, Feng Y, Lu YT, Lin YF, Hung TP, Hsu FC, Liang SY (2017) Force modeling of Inconel 718 laser-assisted end milling under recrystallization effects. Int J Adv Manuf Technol 92(5–8):2965–2974

Karpat Yi, Özel Tr (2006) Predictive analytical and thermal modeling of orthogonal cutting process—part II: effect of tool flank wear on tool forces, stresses, and temperature distributions. J Manuf Sci Eng 128(2):445

Feng Y, Pan Z, Liang SY (2018) Temperature prediction in Inconel 718 milling with microstructure evolution. Int J Adv Manuf Technol 95(9–12):4607–4621

Ning J, Nguyen V, Huang Y, Hartwig KT, Liang SY (2018) Inverse determination of Johnson–Cook model constants of ultra-fine-grained titanium based on chip formation model and iterative gradient search. Int J Adv Manuf Technol 99:1131–1140

Mirkoohi E, Bocchini P, Liang SY (2018) An analytical modeling for process parameter planning in the machining of Ti-6Al-4V for force specifications using an inverse analysis. Int J Adv Manuf Technol 98(9–12):2347–2355

Feng Y, Hung TP, Lu YT, Lin YF, Hsu FC, Lin CF, Lu YC, Lu X, Liang SY (2018) Inverse analysis of Inconel 718 laser-assisted milling to achieve machined surface roughness. Int J Precis Eng Manuf 19(11):1611–1618

Kong X et al (2014) Cutting performance and coated tool wear mechanisms in laser-assisted milling K24 nickel-based superalloy. Int J Adv Manuf Technol 77(9–12):2151–2163

Pan Z et al (2017) Turning force prediction of AISI 4130 considering dynamic recrystallization, vol 50725, p V001T02A040

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Feng, Y., Hung, TP., Lu, YT. et al. Inverse analysis of the tool life in laser-assisted milling. Int J Adv Manuf Technol 103, 1947–1958 (2019). https://doi.org/10.1007/s00170-019-03695-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03695-1