Abstract

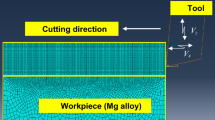

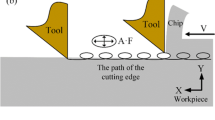

In vibration-assisted milling, vibrations are applied in feed and/or cross-feed directions during micro-milling process, and instantaneous cutting thickness can be changed significantly. As a result, its cutting mechanics also change dramatically. This paper investigates the underlying cutting mechanism of vibration-assisted micro-milling by using finite element (FE) simulations and experiments. A finite element model of vibration-assisted micro-milling process is established for magnesium alloys machining with the Johnson-Cook material model. The vibration-assisted micro-milling is investigated in terms of size effect and material removal mechanism. It is found that vibration frequency has a significant influence on the machining mechanism, e.g. suppression of burr formation and reduction of cutting forces and tool wear. The FE simulation results are compared with the conventional micro-milling and verified by the experimental results.

Similar content being viewed by others

References

Friedrich CR, Vasile MJ (1996) Development of the micromilling process for high-aspect-ratio microstructures. J Microelectromech Syst 5(1):33–38

Bissacco G, Hansen HN, De Chiffre L (2005) Micromilling of hardened tool steel for mould making applications. J Mater Process Technol 167(2-3):201–207

Aramcharoen A, Mativenga PT (2009) Size effect and tool geometry in micromilling of tool steel. Precis Eng 33(4):402–407

Bissacco G, Hansen HN, Slunsky J (2008) Modelling the cutting edge radius size effect for force prediction in micro milling. CIRP Ann Manuf Technol 57(1):113–116

De Oliveira FB et al (2015) Size effect and minimum chip thickness in micromilling. Int J Mach Tools Manuf 89:39–54

Mian AJ, Driver N, Mativenga PT (2011) Identification of factors that dominate size effect in micro-machining. Int J Mach Tools Manuf 51(5):383–394

Chen W, Teng X, Zheng L, Xie W, Huo D (2018) Burr reduction mechanism in vibration-assisted micro milling. Manuf Lett 16:6–9

Shen X-H et al (2012) Ultrasonic vibration-assisted milling of aluminum alloy. Int J Adv Manuf Technol 63(1–4):41–49

Chen W, Huo D, Hale J, Ding H (2018) Kinematics and tool-workpiece separation analysis of vibration assisted milling. Int J Mech Sci 136:169–178

Uhlmann E, Perfilov I, Oberschmidt D (2015) Two-axis vibration system for targeted influencing of micro-milling. In: Euspen’s 15th International Conference & Exhibition

Tao G et al (2017) Feed-direction ultrasonic vibration− assisted milling surface texture formation. Mater Manuf Process 32(2):193–198 Leuven, Belgium, June 2015, 325–326

Chen W et al (2018) Surface texture formation by non-resonant vibration assisted micro milling. J Micromech Microeng 28(2):025006

Börner R, Winkler S, Junge T, Titsch C, Schubert A, Drossel W-G (2018) Generation of functional surfaces by using a simulation tool for surface prediction and micro structuring of cold-working steel with ultrasonic vibration assisted face milling. J Mater Process Technol 255:749–759

Lian H, Guo Z, Huang Z, Tang Y, Song J (2013) Experimental research of Al6061 on ultrasonic vibration assisted micro-milling. Procedia CIRP 6:561–564

Shen X-H et al (2012) A study of surface roughness variation in ultrasonic vibration-assisted milling. Int J Adv Manuf Technol 58(5–8):553–561

Ding H, Chen SJ, Ibrahim R, Cheng K (2011) Investigation of the size effect on burr formation in two-dimensional vibration-assisted micro end milling. Proc Inst Mech Eng B J Eng Manuf 225(11):2032–2039

Ding H et al (2010) Experimental study on machinability improvement of hardened tool steel using two dimensional vibration-assisted micro-end-milling. Int J Mach Tools Manuf 50(12):1115–1118

Zemann R, Kain L, Bleicher F (2014) Vibration assisted machining of carbon fibre reinforced polymers. Proced Eng 69:536–543

Cheng K, Huo D (2013) Micro-cutting: fundamentals and applications. Wiley

Ulacia I, Salisbury CP, Hurtado I, Worswick MJ (2011) Tensile characterization and constitutive modeling of AZ31B magnesium alloy sheet over wide range of strain rates and temperatures. J Mater Process Technol 211:830–839

Funding

This work was financially supported by the National Natural Science Foundation of China (Grant No.51505107), the National Science and Technology Program (2015DFA70630) and the Engineering and Physical Sciences Research Council (EP/M020657/1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, W., Zheng, L., Teng, X. et al. Finite element simulation and experimental investigation on cutting mechanism in vibration-assisted micro-milling. Int J Adv Manuf Technol 105, 4539–4549 (2019). https://doi.org/10.1007/s00170-019-03402-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03402-0