Abstract

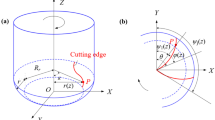

Five-axis milling has becoming more popular and widely used in various fields recently, such as aerospace, aviation, shipbuilding, and so on, owing to its capacity to realize higher precision and efficiency. However, the cutter-workpiece engagement (CWE) determination and cutting force prediction in five-axis milling become complicated and remain a challenge by reason of the engagement geometric complexity. This paper presents a CWE determination method based on cutting edge element modeling in five-axis filleted end milling. In the method, the undeformed chip thickness is deduced by exact analysis of translation and rotation of the cutting edge element, and the CWE determination is performed using designed method based on cutting edge elements classification. Then the cutting force model is built using proposed cutting edge element model and CWE determination method. Five-axis machining validation experiments are conducted in a milling center. The results show the effectiveness of the model and support the analysis of influence rule of cutter attitude angle on cutting force.

Similar content being viewed by others

References

Fontaine M, Devillez A, Moufki A, Dudzinski D (2006) Predictive force model for ball-end milling and experimental validation with a wavelike form machining test. Int J Mach Tool Manuf 46(3):367–380

Guo D, Ren F, Sun Y (2010) An approach to modeling cutting forces in five-axis ball-end milling of curved geometries based on tool motion analysis. J Manuf Sci Eng 132(4):575–590

Aras E, Albedah A (2014) Extracting cutter/workpiece engagements in five-axis milling using solid modeler. Int J Adv Manuf Technol 73(9–12):1351–1362

Kiswanto G, Hendriko H, Duc E (2014) An analytical method for obtaining cutter workpiece engagement during a semi-finish in five-axis milling. Comput Aided Des 55(3):81–93

Boz Y, Erdim H, Lazoglu I (2015) A comparison of solid model and three-orthogonal dexelfield methods for cutter-workpiece engagement calculations in three- and five-axis virtual milling. Int J Adv Manuf Technol 81(5–8):811–823

Taner TL, Ömer Ö, Erhan B (2015) Generalized cutting force model in multi-axis milling using a new engagement boundary determination approach. Int J Adv Manuf Technol 77(1–4):341–355

Ju G, Song Q, Liu Z, Shi J, Wan Y (2015) A solid-analytical-based method for extracting cutter-workpiece engagement in sculptured surface milling. Int J Adv Manuf Technol 80:1297–1310

Gong X, Feng HY (2016) Cutter-workpiece engagement determination for general milling using triangle mesh modeling. J Comput Des Eng 3(2):151–160

Li ZL, Wang XZ, Zhu LM (2016) Arc–surface intersection method to calculate cutter–workpiece engagements for generic cutter in five-axis milling. Comput Aided Des 73:1–10

Erkorkmaz K, Katz A, Hosseinkhani Y, Plakhotnik D, Stautner M, Ismail F (2016) Chip geometry and cutting forces in gear shaping. CIRP Ann Manuf Technol 65(1):133–136

Qiu W, Liu Q, Ding J, Yuan S (2016) Cutting force prediction in orthogonal turn-milling by directly using engagement boundaries. Int J Adv Manuf Technol 86(1–4):963–975

Lotfi S, Wassila B, Gilles D (2017) Cutter workpiece engagement region and surface topography prediction in five-axis ball-end milling. Mach Sci Technol 3:1–22

Luo S, Dong Z, Jun MB (2017) Chip volume and cutting force calculations in 5-axis CNC machining of free-form surfaces using flat-end mills. Int J Adv Manuf Technol 90(1–4):1145–1154

Zhu ZR, Peng FY, Rong Y, Song K, Li ZP, Duan XY (2017) High efficiency simulation of five-axis cutting force based on the symbolically solvable cutting contact boundary model. Int J Adv Manuf Technol 94(1–4):1–21

Zhu Z, Yan R, Peng F, Duan X, Zhou L, Song K, Guo C (2016) Parametric chip thickness model based cutting forces estimation considering cutter runout of five-axis general end milling. Int J Mach Tool Manu 101:35–51

Duan X, Peng F, Yan R, Zhu Z, Huang K, Li B (2016) Estimation of cutter deflection based on study of cutting force and static flexibility. J Manuf Sci Eng 138(4):041001–041015

Duan X, Peng FY, Yan R, Zhu Z, Li B (2015) Experimental study of the effect of tool orientation on cutter deflection in five-axis filleted end dry milling of ultrahigh-strength steel. Int J Adv Manuf Technol 81(1–4):653–666

Paul RP (1981) Robot manipulators: mathematics, programming, and control. The computer control of robot manipulators, vol 28. MIT Press, Cambridge

Funding

This work was supported by National Natural Science Foundation of China under Grant No. 51605346 and China Postdoctoral Science Foundation under Grant No. 2016M602374.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Duan, X., Peng, F., Zhu, Z. et al. Cutting edge element modeling-based cutter-workpiece engagement determination and cutting force prediction in five-axis milling. Int J Adv Manuf Technol 102, 421–430 (2019). https://doi.org/10.1007/s00170-018-3082-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-3082-7