Abstract

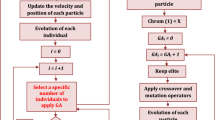

Recently, the pulsed current tungsten arc welding process (PC-TAW) has cemented their potential in various sorts of industrial application such as automobile, aerospace, and structural joining. However, the involvement of multiple process parameters in PC-GTAW process usually makes the process cumbersome to understand; and thereby, it is difficult to develop the mathematical model. Here, in this scientific work, the major efforts have been made to optimize multiple parameters for selected output responses through the use of evolutionary computational approaches. For this purpose, the particle swarm optimization (PSO), simulated annealing (SA) algorithm, and hybrid PSO-SA (HPSOSA) techniques have been employed and compared in terms of the quality responses for input parameters. From the soft computing modeling results, it has been observed that the HPSOSA improved the process performance and has revealed the global optimal solution within minimum interval of time. The developed models were statistically significant at 95% confidence interval. The experimental and mathematical outcomes for the welded specimens are duly supported with microscopic analyses.

Similar content being viewed by others

References

Harinadh V, Edison G, Akella S et al (2017) Multipass welding on inconel material with pulsed current gas tungsten arc welding. Mater Today Proc 4:1452–1458. https://doi.org/10.1016/j.matpr.2017.01.167

Devendranath Ramkumar K, Chandrasekhar A, Srivastava A, Preyas H, Chandra S, Dev S, Arivazhagan N (2016) Effects of filler metals on the segregation, mechanical properties and hot corrosion behaviour of pulsed current gas tungsten arc welded super-austenitic stainless steel. J Manuf Process 24:46–61. https://doi.org/10.1016/j.jmapro.2016.07.006

Senthil Kumar T, Balasubramanian V, Sanavullah MY (2007) Influences of pulsed current tungsten inert gas welding parameters on the tensile properties of AA 6061 aluminium alloy. Mater Des 28:2080–2092. https://doi.org/10.1016/j.matdes.2006.05.027

Balasubramanian M, Jayabalan V, Balasubramanian V (2008) Developing mathematical models to predict tensile properties of pulsed current gas tungsten arc welded Ti–6Al–4V alloy. Mater Des 29:92–97. https://doi.org/10.1016/j.matdes.2006.12.001

Manikandan M, Rao MN, Ramanujam R, Ramkumar D, Arivazhagan N, Reddy GM (2014) Optimization of the pulsed current gas tungsten arc welding process parameters for alloy C-276 using the Taguchi method. Procedia Eng 97:767–774. https://doi.org/10.1016/j.proeng.2014.12.307

Tsaur CC (2005) High temperature oxidation and NaCl-induced accelerated corrosion of hot-dip aluminized 9Cr-1Mo and 310 stainless steel. Doctoral dissertation, Texas A&M University

Devendranath Ramkumar K, Arivazhagan N, Narayanan S (2012) Effect of filler materials on the performance of gas tungsten arc welded AISI 304 and Monel 400. Mater Des 40:70–79. https://doi.org/10.1016/j.matdes.2012.03.024

Ramirez JE (2014) Characterization of CSCGMAW titanium rich weld overlays. Weld J 73:338–350

Manikandan M, Sasikumar P, Arul Murugan B et al (2015) Micro-segregation studies on pulsed current gas tungsten arc welding of alloy C-276. Int J Sci Eng Res 6:33–38

Devendranath Ramkumar K, Singh A, Raghuvanshi S, Bajpai A, Solanki T, Arivarasu M, Arivazhagan N, Narayanan S (2015) Metallurgical and mechanical characterization of dissimilar welds of austenitic stainless steel and super-duplex stainless steel – a comparative study. J Manuf Process 19:212–232. https://doi.org/10.1016/j.jmapro.2015.04.005

Devendranath Ramkumar K, Jagat Sai R, Santhosh Reddy V, Gundla S, Harsha Mohan T, Saxena V, Arivazhagan N (2015) Effect of filler wires and direct ageing on the microstructure and mechanical properties in the multi-pass welding of Inconel 718. J Manuf Process 18:23–45. https://doi.org/10.1016/j.jmapro.2015.01.001

Mortezaie A, Shamanian M (2014) An assessment of microstructure, mechanical properties and corrosion resistance of dissimilar welds between Inconel 718 and 310S austenitic stainless steel. Int J Press Vessel Pip 116:37–46. https://doi.org/10.1016/j.ijpvp.2014.01.002

Sireesha M, Albert SK, Shankar V, Sundaresan S (2000) A comparative evaluation of welding consumables for dissimilar welds between 316LN austenitic stainless steel and alloy 800. J Nucl Mater 279:65–76. https://doi.org/10.1016/S0022-3115(99)00275-5

Jang C, Lee J, Sung Kim J, Eun Jin T (2008) Mechanical property variation within Inconel 82/182 dissimilar metal weld between low alloy steel and 316 stainless steel. Int J Press Vessel Pip 85:635–646. https://doi.org/10.1016/j.ijpvp.2007.08.004

Hajiannia I, Shamanian M, Kasiri M (2013) Microstructure and mechanical properties of AISI 347 stainless steel/A335 low alloy steel dissimilar joint produced by gas tungsten arc welding. Mater Des 50:566–573

Arivarasu M, Mageshkumar K, Rajan DN, Murugan BA, Prasanth P, Sukumar S, Vimalanathan R (2017) Analysis of metallurgical and mechanical properties of continuous and pulsed current gas tungsten arc welded alloy C-276 with duplex stainless steel. Trans Indian Inst Metals 70:661–669. https://doi.org/10.1007/s12666-017-1045-6

Srikanth A, Manikandan M (2017) Development of welding technique to avoid the sensitization in the alloy 600 by conventional gas tungsten arc welding method. J Manuf Process 30:452–466. https://doi.org/10.1016/j.jmapro.2017.10.014

Ramkumar KD, Bhalodi AJ, Ashokbhai HJ, Balaji A, Aravind S, Aravind KM, Varma V (2017) Effect of Mo-rich fillers in pulsed current gas tungsten arc welding of Inconel 718 for improved strength and hot corrosion resistance. J Mater Eng Perform 26:5620–5640. https://doi.org/10.1007/s11665-017-3009-8

Mia M, Morshed MS, Kharshiduzzaman M, Razi MH, Mostafa MR, Rahman SMS, Ahmad I, Hafiz MT, Kamal AM (2018) Prediction and optimization of surface roughness in minimum quantity coolant lubrication applied turning of high hardness steel. Measurement 118:43–51. https://doi.org/10.1016/j.measurement.2018.01.012

Mia M (2017) Multi-response optimization of end milling parameters under through-tool cryogenic cooling condition. Measurement 111(Supplement C):134–145. https://doi.org/10.1016/j.measurement.2017.07.033

Rao RV, Rai DP, Balic J (2016) Multi-objective optimization of machining and micro-machining processes using non-dominated sorting teaching--learning-based optimization algorithm. J Intell Manuf. https://doi.org/10.1007/s10845-016-1210-5

Rao RV, Rai DP (2017) Optimisation of welding processes using quasi-oppositional-based Jaya algorithm. J Exp Theor Artif Intell 29:1099–1117. https://doi.org/10.1080/0952813X.2017.1309692

Abhishek K, Rakesh Kumar V, Datta S, Mahapatra SS (2017) Parametric appraisal and optimization in machining of CFRP composites by using TLBO (teaching--learning based optimization algorithm). J Intell Manuf 28:1769–1785. https://doi.org/10.1007/s10845-015-1050-8

Rao RV, Rai DP, Balic J (2017) Multi-objective optimization of abrasive waterjet machining process using Jaya algorithm and PROMETHEE method. J Intell Manuf. https://doi.org/10.1007/s10845-017-1373-8

Balasubramanian M, Jayabalan V, Balasubramanian V (2008) Optimizing pulsed current parameters to minimize corrosion rate in gas tungsten arc welded titanium alloy. Int J Adv Manuf Technol 39:474–481. https://doi.org/10.1007/s00170-007-1233-3

Srirangan AK, Paulraj S (2016) Multi-response optimization of process parameters for TIG welding of Incoloy 800HT by Taguchi grey relational analysis. Eng Sci Technol an Int J 19:811–817. https://doi.org/10.1016/j.jestch.2015.10.003

Ibrahim M, Maqsood S, Khan R et al (2016) Optimization of gas tungsten arc welding parameters on penetration depth and bead width using Taguchi method. J Eng Appl Sci 35:51–59

Yousefieh M, Shamanian M, Saatchi A (2011) Optimization of the pulsed current gas tungsten arc welding (PCGTAW) parameters for corrosion resistance of super duplex stainless steel (UNS S32760) welds using the Taguchi method. J Alloys Compd 509:782–788. https://doi.org/10.1016/j.jallcom.2010.09.087

Choudhury N (2013) Design optimization of process parameters for TIG welding based on Taguchi method. Int J Curr Eng Technol 12–16. https://doi.org/10.14741/ijcet/spl.2.2014.03

Kangazian J, Shamanian M (2016) Multiresponse optimization of pulsed-current gas tungsten arc welding (PCGTAW) for AISI 304 stainless steel to St 52 steel dissimilar welds. Metallogr Microstruct Anal 5:241–250. https://doi.org/10.1007/s13632-016-0277-x

Joseph J, Muthukumaran S (2016) Optimization of pulsed current GTAW process parameters for sintered hot forged AISI 4135 P/M steel welds by simulated annealing and genetic algorithm. J Mech Sci Technol 30:145–155. https://doi.org/10.1007/s12206-015-1218-3

BABU S, TS KUMAR, BALASUBRAMANIAN V (2008) Optimizing pulsed current gas tungsten arc welding parameters of AA6061 aluminium alloy using Hooke and Jeeves algorithm. Trans Nonferrous Metals Soc China 18:1028–1036. https://doi.org/10.1016/S1003-6326(08)60176-4

Yildiz BS, Yildiz AR (2018) Comparison of grey wolf, whale, water cycle, ant lion and sine-cosine algorithms for the optimization of a vehicle engine connecting rod. Mater Test 60:311–315. https://doi.org/10.3139/120.111153

Yildiz BS (2017) A comparative investigation of eight recent population-based optimisation algorithms for mechanical and structural design problems. Int J Veh Des 73:208. https://doi.org/10.1504/IJVD.2017.082603

Yildiz BS, Yildiz AR (2017) Moth-flame optimization algorithm to determine optimal machining parameters in manufacturing processes. Mater Test 59:425–429. https://doi.org/10.3139/120.111024

Karagoz S, Yildiz AR (2017) A comparison of recent metaheuristic algorithms for crashworthiness optimisation of vehicle thin-walled tubes considering sheet metal forming effects. Int J Veh Des 73:179–188. https://doi.org/10.1504/IJVD.2017.082593

Pholdee N, Bureerat S, Yildiz AR (2017) Hybrid real-code population-based incremental learning and differential evolution for many-objective optimisation of an automotive floor-frame. Int J Veh Des 73:20–53. https://doi.org/10.1504/IJVD.2017.082578

Yildiz BS, Lekesiz H (2017) Fatigue-based structural optimisation of vehicle components. Int J Veh Des 73:54–62. https://doi.org/10.1504/IJVD.2017.082579

Yildiz AR (2013) Cuckoo search algorithm for the selection of optimal machining parameters in milling operations. Int J Adv Manuf Technol 64:55–61. https://doi.org/10.1007/s00170-012-4013-7

Kiani M, Yildiz AR (2016) A comparative study of non-traditional methods for vehicle crashworthiness and NVH optimization. Arch Comput Meth Eng 23:723–734. https://doi.org/10.1007/s11831-015-9155-y

Yildiz AR, Kurtuluş E, Demirci E et al (2016) Optimization of thin-wall structures using hybrid gravitational search and Nelder-Mead algorithm. Mater Test 58:75–78. https://doi.org/10.3139/120.110823

Yildiz BS, Lekesiz H, Yildiz AR (2016) Structural design of vehicle components using gravitational search and charged system search algorithms. Mater Test 58:79–81. https://doi.org/10.3139/120.110819

Yildiz AR (2012) A comparative study of population-based optimization algorithms for turning operations. Inf Sci (Ny) 210:81–88. https://doi.org/10.1016/j.ins.2012.03.005

Yildiz AR (2013) Comparison of evolutionary-based optimization algorithms for structural design optimization. Eng Appl Artif Intell 26:327–333. https://doi.org/10.1016/j.engappai.2012.05.014

Yildiz AR, Saitou K (2011) Topology synthesis of multicomponent structural assemblies in continuum domains. J Mech Des 133:11008–11009

Yildiz AR (2009) Hybrid immune-simulated annealing algorithm for optimal design and manufacturing. Int J Mater Prod Technol 34:217–226. https://doi.org/10.1504/IJMPT.2009.024655

Yildiz AR (2008) A novel particle swarm optimization approach for product design and manufacturing. Int J Adv Manuf Technol 40:617–628. https://doi.org/10.1007/s00170-008-1453-1

Yildiz AR, Öztürk F (2010) Hybrid Taguchi-harmony search approach for shape optimization. In: Geem ZW (ed) Recent Adv. Harmon. Search Algorithm. Springer Berlin Heidelberg, Berling, pp 89–98

Mia M, Dhar NR (2018) Modeling of surface roughness using RSM, FL and SA in dry hard turning. Arab J Sci Eng 43(3):1125–1136. https://doi.org/10.1007/s13369-017-2754-1

Singh G, Gupta MK, Mia M, Sharma VS (2018) Modeling and optimization of tool wear in MQL-assisted milling of Inconel 718 superalloy using evolutionary techniques. Int J Adv Manuf Technol 97:481–494. https://doi.org/10.1007/s00170-018-1911-3

Prakash C, Singh S, Singh M, Verma K, Chaudhary B, Singh S (2018) Multi-objective particle swarm optimization of EDM parameters to deposit HA-coating on biodegradable Mg-alloy. Vacuum 158:180–190. https://doi.org/10.1016/j.vacuum.2018.09.050

Prakash C, Singh S, Singh M et al (2018) Multi-objective optimization of MWCNT mixed electric discharge machining of Al–30SiCp MMC using particle swarm optimization BT - futuristic composites : behavior, characterization, and manufacturing. In: Bains PS, Zitoune R, Yazdani M (eds) Sidhu SS. Springer Singapore, Singapore, pp 145–164

Javidrad F, Nazari M (2017) A new hybrid particle swarm and simulated annealing stochastic optimization method. Appl Soft Comput 60:634–654. https://doi.org/10.1016/j.asoc.2017.07.023

Shieh H-L, Kuo C-C, Chiang C-M (2011) Modified particle swarm optimization algorithm with simulated annealing behavior and its numerical verification. Appl Math Comput 218:4365–4383. https://doi.org/10.1016/j.amc.2011.10.012

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prakash, C., Singh, S., Singh, M. et al. Multi-objective parametric appraisal of pulsed current gas tungsten arc welding process by using hybrid optimization algorithms. Int J Adv Manuf Technol 101, 1107–1123 (2019). https://doi.org/10.1007/s00170-018-3017-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-3017-3