Abstract

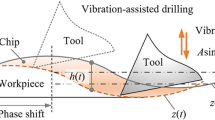

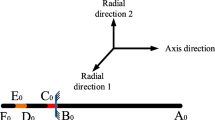

Increasing demands call for the burr-free workpiece in precision manufacturing. Low-frequency vibration-assisted drilling (LFVAD) has been applied to improve the fabrication process. Prediction and minimization of burr size are one of the major research topics in precision machining. In this paper, an LFVAD parameters optimization model was proposed including harmony search (HS) algorithm and a modified LFVAD burr height analytical model. The burr height model of LFVAD was developed using existing analytical burr height model for conventional drilling (CD) and vibration-assisted drilling (VAD). The developed burr height models were then employed with HS algorithm, which is a new meta-heuristic optimization method based on the imitation of music improvisation process, to determine the optimal machining parameters for a given twist drill that results in minimum exit burr height. Experimental results show that the burr height of the optimized LFVAD decreased by 52.75% compared with the CD, and decreased by 17.59% compared with the un-optimized LFVAD. The simulation and experimental results demonstrate that under suitable LFVAD parameters, the burr height could be reduced.

Similar content being viewed by others

References

Garg A, Tai K, Vijayaraghavan V, Singru PM (2014) Mathematical modelling of burr height of the drilling process using a statistical-based multi-gene genetic programming approach. Int J Adv Manuf Technol 73(1–4):113–126

Azarrang S, Baseri H (2015) Selection of dry drilling parameters for minimal burr size and desired drilling quality. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of Process Mechanical Engineering 231(3):480–489

Gaitonde VN, Karnik SR, Achyutha BT, Siddeswarappa B (2008) Genetic algorithm-based burr size minimization in drilling of AISI 316L stainless steel. J Mater Process Technol 197(1–3):225–236

Rajmohan T, Palanikumar K (2012) Optimization of machining parameters for surface roughness and Burr height in drilling hybrid composites. Mater Manuf Process 27(3):320–328

Gillespie LK (1979) Deburring precision miniature parts. Precis Eng 1(4):189–198

Chang SSF, Bone GM (2005) Burr size reduction in drilling by ultrasonic assistance. Robot Comput Integr Manuf 21(4–5):442–450

Debnath K, Singh I (2017) Low-frequency modulation-assisted drilling of carbon-epoxy composite laminates. J Manuf Process 25:262–273

Wang C, Yaoxiong H, Congxin L (2005) A manufacturing model of helical groove on rotary burr and a universal post processing method. Int J Adv Manuf Technol 29(1–2):9–16

Niknam SA, Songmene V (2014) Analytical modelling of slot milling exit burr size. Int J Adv Manuf Technol 73(1–4):421–432

Zhang T, Liu Z, Xu C (2013) Influence of size effect on burr formation in micro cutting. Int J Adv Manuf Technol 68(9–12):1911–1917

Min S, Dornfeld DA, Nakao Y (2003) Influence of exit surface angle on drilling Burr formation. J Manuf Sci Eng 125(4):637

Kundu S, Das S, Saha PP (2014) Optimization of drilling parameters to minimize burr by providing back-up support on aluminium alloy. Procedia Engineering 97:230–240

Mondal N, Sardar BS, Halder RN, Das S (2014) Observation of drilling burr and finding out the condition for minimum burr formation. Int J Manuf Eng 2014(1):1–12

Takeyama H, Kato S (1991) Burrless drilling by means of ultrasonic vibration. CIRP Ann Manuf Technol 40(1):83–86

Zhang L-B, Wang L-J, Liu X-Y, Zhao H-W, Wang X, Luo H-Y (2001) Mechanical model for predicting thrust and torque in vibration drilling fibre-reinforced composite materials. Int J Mach Tools Manuf 41(5):641–657

Patra K, Jha AK, Szalay T, Ranjan J, Monostori L (2017) Artificial neural network based tool condition monitoring in micro mechanical peck drilling using thrust force signals. Precis Eng 48:279–291

Chatterjee S, Mahapatra SS, Abhishek K (2016) Simulation and optimization of machining parameters in drilling of titanium alloys. Simul Model Pract Theory 62:31–48

Rajmohan T, Palanikumar K, Prakash S (2013) Grey-fuzzy algorithm to optimise machining parameters in drilling of hybrid metal matrix composites. Compos Part B 50:297–308

Nam JS, Kim DH, Chung H, Lee SW (2015) Optimization of environmentally benign micro-drilling process with nanofluid minimum quantity lubrication using response surface methodology and genetic algorithm. J Clean Prod 102:428–436

Zong WG, Kim JH, Loganathan GV (2001) A new heuristic optimization algorithm: harmony search. Simulation Transactions of the Society for Modeling & Simulation International 76(2):60–68

Shabani M, Abolghasem Mirroshandel S, Asheri H (2017) Selective refining harmony search: a new optimization algorithm. Expert Syst Appl 81:423–443

Cheng M-Y, Prayogo D, Wu Y-W, Lukito MM (2016) A hybrid harmony search algorithm for discrete sizing optimization of truss structure. Autom Constr 69:21–33

He Z, Pan B, Liu Z, Tang X (2017) The mechanical arm control based on harmony search genetic algorithm. Clust Comput 20(4):3251–3261

Abhishek K, Datta S, Mahapatra SS (2016) Multi-objective optimization in drilling of CFRP (polyester) composites: application of a fuzzy embedded harmony search (HS) algorithm. Measurement 77:222–239

Pan Q-K, Suganthan PN, Tasgetiren MF, Liang JJ (2010) A self-adaptive global best harmony search algorithm for continuous optimization problems. Appl Math Comput 216(3):830–848

Mahdavi M, Fesanghary M, Damangir E (2007) An improved harmony search algorithm for solving optimization problems. Appl Math Comput 188(2):1567–1579

Keshtegar B, Hao P, Wang Y, Hu Q (2018) An adaptive response surface method and Gaussian global-best harmony search algorithm for optimization of aircraft stiffened panels. Appl Soft Comput 66:196–207

Park IW, Dornfeld DA (2000) A study of Burr formation processes using the finite element method: part I. J Eng Mater Technol 122(2):305–311

Kim J, Dornfeld DA (2002) Development of an analytical model for drilling burr formation in ductile materials. J Eng Mater Technol 124(2):192

Brehl DE, Dow TA (2008) Review of vibration-assisted machining. Precis Eng 32(3):153–172

Chang SSF, Bone GM (2010) Burr height model for vibration assisted drilling of aluminum 6061-T6. Precis Eng 34(3):369–375

Chandrasekharan V, Kapoor S, DeVor R (1995) A mechanistic approach to predicting the cutting forces in drilling: with application to fiber-reinforced composite materials. J Eng Ind 117(4):559–570

Paul A, Kapoor SG, DeVor RE (2005) A chisel edge model for arbitrary drill point geometry. J Manuf Sci Eng 127(1):23

Guibert N, Paris H, Rech J (2008) A numerical simulator to predict the dynamical behavior of the self-vibratory drilling head. Int J Mach Tools Manuf 48(6):644–655

Audy J (2008) A study of computer-assisted analysis of effects of drill geometry and surface coating on forces and power in drilling. J Mater Process Technol 204(1–3):130–138

Williams R (1974) A study of the drilling process. J Eng Ind 96(4):1207–1215

Ucun İ (2016) 3D finite element modelling of drilling process of Al7075-T6 alloy and experimental validation. J Mech Sci Technol 30(4):1843–1850

Gaitonde VN, Karnik SR (2010) Minimizing burr size in drilling using artificial neural network (ANN)-particle swarm optimization (PSO) approach. J Intell Manuf 23(5):1783–1793

Abdelhafeez AM, Soo SL, Aspinwall DK, Dowson A, Arnold D (2015) Burr formation and hole quality when drilling titanium and aluminium alloys. Procedia CIRP 37:230–235

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shaomin, L., Deyuan, Z., Daxi, G. et al. Modeling and drilling parameters optimization on burr height using harmony search algorithm in low-frequency vibration-assisted drilling. Int J Adv Manuf Technol 101, 2313–2325 (2019). https://doi.org/10.1007/s00170-018-2997-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2997-3