Abstract

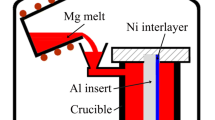

Mg/Al bimetal was successfully prepared using a novel lost-foam casting (LFC) liquid-liquid compound process with an Al interlayer, and the interface characteristics including microstructure, mechanical properties, and fracture behavior of the Mg/Al bimetal were investigated in this paper. The results show that the mixing of AZ91D and A356 liquid metals was fully avoided by using the Al interlayer. A metallurgical bonding between the AZ91D alloy matrix and the A356 alloy matrix was achieved, obtaining a compact interface. The interface was constituted by the Al12Mg17 + δ (Mg) eutectic and the Al3Mg2 and Mg2Si reaction layers, which were respectively next to the AZ91D alloy matrix and the A356 alloy matrix. The reaction layers had much higher microhardnesses compared with the microhardnesses of the matrixes, and the highest microhardness up to 275–299 HV was obtained in the reaction layer next to the Al matrix. A brittle fracture morphology was observed in the fractured surface of the Mg/Al bimetal, and the fracture mainly initiated with the fracture of the reaction layer close to the Al matrix.

Similar content being viewed by others

References

Jiang WM, Chen X, Wang BJ, Fan ZT, Wu HB (2016) Effects of vibration frequency on microstructure, mechanical properties, and fracture behavior of A356 aluminum alloy obtained by expendable pattern shell casting. Int J Adv Manuf Technol 83(1–4):167–175. https://doi.org/10.1007/s00170-015-7586-0

Zhang H, Chen YQ, Luo AA (2014) A novel aluminum surface treatment for improved bonding in magnesium/aluminum bimetallic castings. Scr Mater 86:52–55. https://doi.org/10.1016/j.scriptamat.2014.05.007

Li GY, Jiang WM, Fan ZT, Jiang ZL, Liu XW, Liu FC (2017) Effects of pouring temperature on microstructure, mechanical properties, and fracture behavior of Al/Mg bimetallic composites produced by lost foam casting process. Int J Adv Manuf Technol 91(1–4):1355–1368. https://doi.org/10.1007/s00170-016-9810-y

Kund NK (2018) Effect of tilted plate vibration on solidification and microstructural and mechanical properties of semisolid cast and heat-treated A356 Al alloy. Int J Adv Manuf Technol 97(5–8):1617–1626. https://doi.org/10.1007/s00170-018-2063-1

Campbell J (2011) Complete casting handbook, first edn. Elsevier Press, UK

Campbell J (2006) Entrainment defects. Mater Sci Technol 22(2):127–145. https://doi.org/10.1179/174328406X74248

Hajjari E, Divandari M, Razavi SH, Homma T, Kamado S (2012) Microstructure characteristics and mechanical properties of Al 413/Mg joint in compound casting process. Metall Mater Trans A 43(12):4667–4677. https://doi.org/10.1007/s11661-012-1296-0

Xu GC, Luo AA, Chen YQ, Sachdev AK (2014) Interfacial phenomena in magnesium/aluminum bi-metallic castings. Mater Sci Eng A 595:154–158. https://doi.org/10.1016/j.msea.2013.11.093

Jiang WM, Fan ZT, Li GY, Yang L, Liu XW (2016) Effects of melt-to-solid insert volume ratio on the microstructures and mechanical properties of Al/Mg bimetallic castings produced by lost foam casting. Metall Mater Trans A 47(12):6487–6497. https://doi.org/10.1007/s11661-016-3788-9

Liu JC, Hu J, Nie XY, Li HX, Du Q, Zhang JS, Zhuang LZ (2015) The interface bonding mechanism and related mechanical properties of Mg/Al compound materials fabricated by insert molding. Mater Sci Eng A 635:70–76. https://doi.org/10.1016/j.msea.2015.03.074

Islam MR, Ishak M, Shah LH, Idris SR, Meriç C (2016) Dissimilar welding of A7075-T651 and AZ31B alloys by gas metal arc plug welding method. Int J Adv Manuf Technol 88(9–12):2773–2783. https://doi.org/10.1007/s00170-016-8993-6

Tabasi M, Farahani M, Besharati Givi MK, Farzami M, Moharami A (2016) Dissimilar friction stir welding of 7075 aluminum alloy to AZ31 magnesium alloy using SiC nanoparticles. Int J Adv Manuf Technol 86(1–4):705–715. https://doi.org/10.1007/s00170-015-8211-y

Mofid MA, Abdollah-Zadeh A, Gür CH (2014) Investigating the formation of intermetallic compounds during friction stir welding of magnesium alloy to aluminum alloy in air and under liquid nitrogen. Int J Adv Manuf Technol 71(5–8):1493–1499. https://doi.org/10.1007/s00170-013-5565-x

Zhao Y, Jiang S, Yang SF, Lu ZP, Yan K (2016) Influence of cooling conditions on joint properties and microstructures of aluminum and magnesium dissimilar alloys by friction stir welding. Int J Adv Manuf Technol 83(1–4):673–679. https://doi.org/10.1007/s00170-015-7624-y

Manladan SM, Yusof F, Ramesh S, Fadzil M (2016) A review on resistance spot welding of magnesium alloys. Int J Adv Manuf Technol 86(5–8):1805–1825. https://doi.org/10.1007/s00170-015-8258-9

Feng B, Xin YC, Yu HH, Hong R, Liu Q (2016) Mechanical behavior of a Mg/Al composite rod containing a soft Mg sleeve and an ultra hard Al core. Mater Sci Eng A 675:204–211. https://doi.org/10.1016/j.msea.2016.08.069

Feng B, Xin YC, Guo FL, Yu HH, Wu Y, Liu Q (2016) Compressive mechanical behavior of Al/Mg composite rods with different types of Al sleeve. Acta Mater 120:379–390. https://doi.org/10.1016/j.actamat.2016.08.079

Zha M, Meng XT, Zhang HM, Zhang XH, Jia HL, Li YJ, Zhang JY, Wang HY, Jiang QC (2017) High strength and ductile high solid solution Al-Mg alloy processed by a novel hard-plate rolling route. J Alloys Compd 728:872–877. https://doi.org/10.1016/j.jallcom.2017.09.017

Gali OA, Shafiei M, Hunter JA, Riahi AR (2016) The initiation of roll coating buildup during thermomechanical processing of aluminum-magnesium alloys. Surf Coat Technol 308:328–336. https://doi.org/10.1016/j.surfcoat.2016.07.102

Dai XY, Zhang HT, Wang B, Ji A, Liu JH, Feng JC (2016) Improving weld strength of arc-assisted ultrasonic seam welded Mg/Al joint with Sn interlayer. Mater Des 98:262–271. https://doi.org/10.1016/j.matdes.2016.02.095

Liu F, Zhang ZD, Liu LM (2012) Microstructure evolution of Al/Mg butt joints welded by gas tungsten arc with Zn filler metal. Mater Charact 69:84–89. https://doi.org/10.1016/j.matchar.2012.04.012

Zhang HT, Dai XY, Feng JC (2014) Joining of aluminum and magnesium via pre-roll-assisted A-TIG welding with Zn interlayer. Mater Lett 122:49–51. https://doi.org/10.1016/j.matlet.2014.02.008

Griffiths WD, Ainsworth MJ (2016) Instability of the liquid metal-pattern interface in the lost foam casting of aluminum alloys. Metall Mater Trans A 47:3137–3149. https://doi.org/10.1007/s11661-016-3461-3

Jiang WM, Fan ZT, Liu DJ, Liao DF, Zhao Z, Dong XP, Wu HB (2012) Influence of process parameters on filling ability of A356 aluminium alloy in expendable pattern shell casting with vacuum and low pressure. Int J Cast Metal Res 25(1):47–52. https://doi.org/10.1179/1743133611Y.0000000014

Charchi A, Rezaei M, Hossainpour S, Shayegh J, Falak S (2010) Numerical simulation of heat transfer and fluid flow of molten metal in MMA-St copolymer lost foam casting process. J Mater Process Technol 210(14):2071–2080. https://doi.org/10.1016/j.jmatprotec.2010.07.028

Jiang WM, Fan ZT, Liu DJ, Wu HB (2013) Influence of gas flowrate on filling ability and internal quality of A356 aluminum alloy castings fabricated using the expendable pattern shell casting with vacuum and low pressure. Int J Adv Manuf Technol 67(9–12):2459–2468. https://doi.org/10.1007/s00170-012-4663-5

Emami SM, Divandari M, Hajjari E, Arabi H (2013) Comparison between conventional and lost foam compound casting of Al/Mg light metals. Int J Cast Metal Res 26(1):43–50. https://doi.org/10.1179/1743133612Y.0000000037

Jiang WM, Fan ZT, Liu DJ (2012) Microstructure, tensile properties and fractography of A356 alloy under as-cast and T6 obtained with expendable pattern shell casting process. Trans Nonferrous Metals Soc China 22:S7–S13. https://doi.org/10.1016/S1003-6326(12)61676-8

Guler KA, Kisasoz A, Karaaslan A (2014) Fabrication of Al/Mg bimetal compound casting by lost foam technique and liquid-solid process. Mater Test 56(9):700–702. https://doi.org/10.3139/120.110624

Jiang WM, Li GY, Fan ZT, Wang L, Liu FC (2016) Investigation on the interface characteristics of Al/Mg bimetallic castings processed by lost foam casting. Metall Mater Trans A 47(5):2462–2470. https://doi.org/10.1007/s11661-016-3395-9

Dezellus O, Zhe M, Bosselet F, Rouby D, Viala JC (2011) Mechanical testing of titanium/aluminium-silicon interface. Effect of T6 heat treatment. Mater Sci Eng A 528(6):2795–2803. https://doi.org/10.1016/j.msea.2010.12.036

Jiang WM, Fan ZT, Li GY, Li C (2016) Effects of zinc coating on interfacial microstructures and mechanical properties of aluminum/steel bimetallic composites. J Alloys Compd 678:249–257. https://doi.org/10.1016/j.jallcom.2016.03.276

He K, Zhao JH, Li P, He JS, Tang Q (2016) Investigation on microstructures and properties of arc-sprayed-Al/AZ91D bimetallic material by solid-liquid compound casting. Mater Des 112:553–564. https://doi.org/10.1016/j.matdes.2016.09.085

Hajjari E, Divandari M, Razavi SH, Homma T, Kamado S (2012) Intermetallic compounds and antiphase domains in Al/Mg compound casting. Intermetallics 23:182–186. https://doi.org/10.1016/j.intermet.2011.12.001

Ren QS, Zhao CZ, Li ZB, Zhang HX (2015) Microstructure and mechanical properties of Mg/Al bimetallic composite fabricated by compound casting. Mater Res Innov 19:S73–S78. https://doi.org/10.1179/1432891715Z.0000000001520

Liu ZL, Ji SD, Meng XC (2018) Joining of magnesium and aluminum alloys via ultrasonic assisted friction stir welding at low temperature. Int J Adv Manuf Technol 97(9–12):4127–4136. https://doi.org/10.1007/s00170-018-2255-8

Shah LH, Gerlich A, Zhou Y (2018) Design guideline for intermetallic compound mitigation in Al-Mg dissimilar welding through addition of interlayer. Int J Adv Manuf Technol 94(5–8):2667–2678. https://doi.org/10.1007/s00170-017-1038-y

Jiang Z, Fan Z, Jiang W, Li G, Wu Y, Guan F, Jiang H (2018) Interfacial microstructures and mechanical properties of Mg/Al bimetal produced by a novel liquid-liquid compound casting process. J Mater Process Technol 261:149–158. https://doi.org/10.1016/j.jmatprotec.2018.06.013

Baqer YM, Ramesh S, Yusof F, Manladan SM (2018) Challenges and advances in laser welding of dissimilar light alloys: Al/Mg, Al/Ti, and Mg/Ti alloys. Int J Adv Manuf Technol 95(9–12):4353–4369. https://doi.org/10.1007/s00170-017-1565-6

Liu ZL, Ji SD, Meng XC, Huang RF (2017) Improving joint formation and tensile properties of friction stir welded ultra-thin Al/Mg alloy sheets using a pinless tool assisted by a stationary shoulder. Int J Adv Manuf Technol 93(5–8):2071–2079. https://doi.org/10.1007/s00170-017-0682-6

Funding

This study is supported by the National Natural Science Foundation of China (Nos. 51775204 and 51204124), the fund of the State Key Laboratory of Solidification Processing in NWPU (No. SKLSP201821), the Natural Science Foundation of Hubei Province, China (No. 2017CFB488), and the Analytical and Testing Center, HUST.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, Q., Jiang, Z., Jiang, W. et al. Interface characteristics of Mg/Al bimetal produced by a novel liquid-liquid compound casting process with an Al interlayer. Int J Adv Manuf Technol 101, 1125–1132 (2019). https://doi.org/10.1007/s00170-018-2990-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2990-x