Abstract

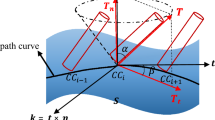

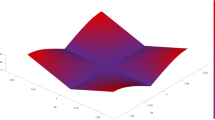

Aiming at tool parameters selection and tool axis control in the four-axis machining process with a ball-end cutter, a GPU-based method is proposed in this paper. Firstly, based on the characteristics of the tool movement in four-axis machining, the feasible domain of discrete space for the tool is defined. Through the analysis of factors affecting the selection of tool parameters, a tool parameter optimization model is established. Secondly, an Automatically Programmed Tools (APT) tool model is used as the tool model. Basically, a simplified model of a ball-end cutter and tool holders is established, and the calculation methods for the critical tool diameters and the critical tool lengths in feasible domains are determined. After that, through the analysis and application of GPU parallel computing technology, a discrete feasible domain calculation, as well as the rapid solution of the critical tool parameters, is realized. To validate the developed method, tool diameters and orientations are optimized for machining of an open blisk. The validation demonstrates that this method can be used to select the optimal tool parameters and to obtain the overall smooth tool orientations.

Similar content being viewed by others

References

Luo M, Yan D, Wu B, Zhang D (2016) Barrel cutter design and toolpath planning for high-efficiency machining of freeform surface. Int J Adv Manuf Technol 85(9):2495–2503. https://doi.org/10.1007/s00170-015-8113-z

Ji W, Wang L, Haghighi A, Givehchi M, Liu X (2018) An enriched machining feature based approach to cutting tool selection. Int J Comput Integr Manuf 31(1):1–10. https://doi.org/10.1080/0951192X.2017.1356472

Veeramani D, Gau YS (1997) Selection of an optimal set of cutting-tools for a general triangular pocket. Int J Prod Res 35(9):2621–2638. https://doi.org/10.1080/002075497194697

Yingjie Z, Li Y (2007) New approach to selecting multiple tools for milling 2.5-D pockets. In: Proceedings of the 2007 IEEE international conference on mechatronics and automation, 5–8 Aug. 2007, Harbin, China, pp 2320–2325. https://doi.org/10.1109/ICMA.2007.4303915

Zhang Y, Ge L (2008) Selecting optimal set of tool sequences for machining of multiple pockets. Int J Adv Manuf Technol 42(3):233–241. https://doi.org/10.1007/s00170-008-1609-z

Yao Z, Gupta SK, Nau DS (2003) Algorithms for selecting cutters in multi-part milling problems. Comput Aided Des 35(9):825–839. https://doi.org/10.1016/S0010-4485(02)00110-0

Lee Y-S, Chang T-C (1995) Application of computational geometry in optimizing 2.5D and 3D NC surface machining. Comput Ind 26(1):41–59. https://doi.org/10.1016/0166-3615(95)80005-0

Chen ZC, Zhang H (2009) Optimal cutter size determination for 2½-axis finish machining of NURBS profile parts. Int J Prod Res 47(22):6279–6293. https://doi.org/10.1080/00207540802353421

Ding XM, Fuh JYH, Lee KS (2001) Interference detection for 3-axis mold machining. Comput Aided Des 33(8):561–569. https://doi.org/10.1016/S0010-4485(00)00097-X

Jensen CG, Red WE, Pi J (2002) Tool selection for five-axis curvature matched machining. Comput Aided Des 34(3):251–266. https://doi.org/10.1016/S0010-4485(01)00086-0

Schmitz TL, Burns TJ, Ziegert JC, Dutterer B, Winfough WR (2004) Tool length-dependent stability surfaces. Mach Sci Technol 8(3):1–21

Yao Q, Luo M, Zhang D, Wu B (2018) Identification of cutting force coefficients in machining process considering cutter vibration. Mech Syst Signal Process 103:39–59. https://doi.org/10.1016/j.ymssp.2017.09.038

Kim S-J (2007) Short and safe tool setting by safe space in NC machining. Int J Adv Manuf Technol 33(9–10):1017–1023. https://doi.org/10.1007/s00170-006-0526-2

Wang N, Tang K (2007) Automatic generation of gouge-free and angular-velocity-compliant five-axis toolpath. Comput Aided Des 39(10):841–852. https://doi.org/10.1016/j.cad.2007.04.003

Luo M, Luo H, Axinte D, Liu D, Mei J, Liao Z (2018) A wireless instrumented milling cutter system with embedded PVDF sensors. Mech Syst Signal Process 110:556–568. https://doi.org/10.1016/j.ymssp.2018.03.040

Wang QH, Li JR, Gong HQ (2007) Graphics-assisted cutter orientation correction for collision-free five-axis machining. Int J Prod Res 45(13):2875–2894. https://doi.org/10.1080/00207540600767798

Ho MC, Hwang YR, Hu CH (2003) Five-axis tool orientation smoothing using quaternion interpolation algorithm. Int J Mach Tool Manu 43(12):1259–1267

Castagnetti C, Duc E, Ray P (2008) The domain of admissible orientation concept: a new method for five-axis tool path optimisation. Comput Aided Des 40(9):938–950. https://doi.org/10.1016/j.cad.2008.07.002

Kersting P, Zabel A (2009) Optimizing NC-tool paths for simultaneous five-axis milling based on multi-population multi-objective evolutionary algorithms. Adv Eng Softw 40(6):452–463. https://doi.org/10.1016/j.advengsoft.2008.04.013

Okitsu Y, Ino F, Hagihara K (2010) High-performance cone beam reconstruction using CUDA compatible GPUs. Parallel Comput 36(2):129–141. https://doi.org/10.1016/j.parco.2010.01.004

Wang CCL, Manocha D (2013) GPU-based offset surface computation using point samples. Comput Aided Des 45(2):321–330. https://doi.org/10.1016/j.cad.2012.10.015

Tang M, Manocha D, Lin J, Tong R (2011) Collision-streams: fast GPU-based collision detection for deformable models. In: Proceedings of ACM SIGGRAPH Symposium on Interactive 3D Graphics and Games (i3D 2011), 18-20 Feb. 2011, San Fransisco, CA, pp 63–70

Pan J, Manocha D (2012) GPU-based parallel collision detection for fast motion planning. Int J Robot Res 31(2):187–200. https://doi.org/10.1177/0278364911429335

Bi Q, Wang Y, Ding H (2010) A GPU-based algorithm for generating collision-free and orientation-smooth five-axis finishing tool paths of a ball-end cutter. Int J Prod Res 48(4):1105–1124

Morell-Giménez V, Jimeno-Morenilla A, García-Rodríguez J (2013) Efficient tool path computation using multi-core GPUs. Comput Ind 64(1):50–56. https://doi.org/10.1016/j.compind.2012.09.009

Hsieh H-T, Chu C-H (2011) Particle swarm optimisation (PSO)-based tool path planning for 5-axis flank milling accelerated by graphics processing unit (GPU). Int J Comput Integr Manuf 24(7):676–687. https://doi.org/10.1080/0951192X.2011.570792

Abecassis F, Lavernhe S, Tournier C, Boucard P (2015) Performance evaluation of CUDA programming for 5-axis machining multi-scale simulation. Comput Ind 71:1–9

Luo M, Luo H, Zhang D, Tang K (2018) Improving tool life in multi-axis milling of Ni-based superalloy with ball-end cutter based on the active cutting edge shift strategy. J Mater Process Technol 252:105–115. https://doi.org/10.1016/j.jmatprotec.2017.09.010

López de Lacalle LN, Lamikiz A, Sánchez JA, Salgado MA (2004) Effects of tool deflection in the high-speed milling of inclined surfaces. Int J Adv Manuf Technol 24(9):621–631. https://doi.org/10.1007/s00170-003-1723-x

Chen ZC, Liu G (2008) An intelligent approach to multiple cutters of maximum sizes for three-axis milling of sculptured surface parts. J Manuf Sci Eng 131(1):014501–014501. https://doi.org/10.1115/1.3039518

Wang J, Luo M, Zhang D (2018) A GPU-accelerated approach for collision detection and tool posture modification in multi-axis machining. IEEE Access 6:35132–35142. https://doi.org/10.1109/ACCESS.2018.2848938

Funding

This study is co-supported by the China Major National Science and Technology Projects (No. 2015ZX04001202) and the 111 project of China (No. B13044).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Zhang, D., Luo, M. et al. A GPU-based tool parameters optimization and tool orientation control method for four-axis milling with ball-end cutter. Int J Adv Manuf Technol 102, 1107–1125 (2019). https://doi.org/10.1007/s00170-018-2954-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2954-1