Abstract

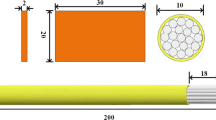

This paper investigates the effects of process parameters on the joint strength and process robustness when multi-layered joints of dissimilar metals are produced by ultrasonic metal welding (UMW). Three layers of 0.3-mm aluminium sheet are welded with a single 1.0-mm copper sheet which is representative of electric vehicle battery interconnects. A process robustness study in which welding pressure, amplitude of vibration and welding time are varied to produce satisfactory welds is reported. The weld quality is evaluated by performing lap shear and T-peel tests where maximum loads are considered as the quality indicator. Response surfaces are developed to identify the relationship and sensitivity between the input process parameters and output quality indicators. A feasible weldability zone is defined for the first time by identifying the under-weld, good-weld and over-weld conditions based on load-displacement curves and corresponding failure modes. Relying on the weldability zone and response surfaces, multi-objective optimisation is performed to obtain maximum lap shear and T-peel strength which resulted in Pareto frontier or trade-off curve between both objectives. An optimal joint is selected from the Pareto front which is verified and validated by performing confirmation experiments, and further, used for T-peel strength analysis of different interfaces of the multi-layered joint. To conclude, this paper determines both the optimal weld parameters and the robust operating range.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

Shakil M, Tariq NH, Ahmad M, Choudhary MA, Akhter JI, Babu SS (2014) Effect of ultrasonic welding parameters on microstructure and mechanical properties of dissimilar joints. Mater Des 55:263–273. https://doi.org/10.1016/j.matdes.2013.09.074

Elangovan S, Prakasan K, Jaiganesh V (2010) Optimization of ultrasonic welding parameters for copper to copper joints using design of experiments. Int J Adv Manuf Technol 51(1):163–171. https://doi.org/10.1007/s00170-010-2627-1

Siddiq A, Ghassemieh E (2008) Thermomechanical analyses of ultrasonic welding process using thermal and acoustic softening effects. Mech Mater 40(12):982–1000. https://doi.org/10.1016/j.mechmat.2008.06.004

Kim TH, Yum J, Hu SJ, Spicer JP, Abell JA (2011) Process robustness of single lap ultrasonic welding of thin, dissimilar materials. CIRP Ann Manuf Technol 60(1):17–20. https://doi.org/10.1016/j.cirp.2011.03.016

Neppiras EA (1965) Ultrasonic welding of metals. Ultrasonics 3(3):128–135. https://doi.org/10.1016/S0041-624X(65)80003-8

Bakavos D, Prangnell PB (2010) Mechanisms of joint and microstructure formation in high power ultrasonic spot welding 6111 aluminium automotive sheet. Mater Sci Eng A 527(23):6320–6334. https://doi.org/10.1016/j.msea.2010.06.038

Lee SS, Kim TH, Hu SJ, Cai WW, Abell JA (2010) Joining technologies for automotive lithium-ion battery manufacturing: a review. In: ASME 2010 International Manufacturing Science and Engineering Conference, Pennsylvania, USA, pp 541–549

Zhang CQ, Robson JD, Prangnell PB (2016) Dissimilar ultrasonic spot welding of aerospace aluminum alloy AA2139 to titanium alloy TiAl6V4. J Mater Process Technol 231:382–388. https://doi.org/10.1016/j.jmatprotec.2016.01.008

Ventrella VA, Berretta JR, de Rossi W (2010) Pulsed Nd:YAG laser seam welding of AISI 316L stainless steel thin foils. J Mater Process Technol 210(14):1838–1843. https://doi.org/10.1016/j.jmatprotec.2010.06.015

Hirata Y (2003) Pulsed arc welding. Weld Int 17(2):98–115. https://doi.org/10.1533/wint.2003.3075

Brand MJ, Schmidt PA, Zaeh MF, Jossen A (2015) Welding techniques for battery cells and resulting electrical contact resistances. J Energy Storage 1:7–14. https://doi.org/10.1016/j.est.2015.04.001

De Vries E (2004) Mechanics and mechanisms of ultrasonic metal welding. The Ohio State University

Das A, Li D, Williams D, Greenwood D (2018) Joining technologies for automotive battery systems manufacturing. World Electr Veh J 9(2):22. https://doi.org/10.3390/wevj9020022

Annoni M, Carboni M (2011) Ultrasonic metal welding of AA 6022-T4 lap joints: part I – technological characterisation and static mechanical behaviour. Sci Technol Weld Join 16(2):107–115. https://doi.org/10.1179/1362171810Y.0000000014

Matsuoka S-i, Imai H (2009) Direct welding of different metals used ultrasonic vibration. J Mater Process Technol 209(2):954–960. https://doi.org/10.1016/j.jmatprotec.2008.03.006

Matsuoka S-i (1994) Ultrasonic welding of ceramic/metal. J Mater Process Technol 47(1):185–196. https://doi.org/10.1016/0924-0136(94)90094-9

Dinda SK, Basiruddin Sk M, Roy GG, Srirangam P (2016) Microstructure and mechanical properties of electron beam welded dissimilar steel to Fe–Al alloy joints. Mater Sci Eng A 677:182–192. https://doi.org/10.1016/j.msea.2016.09.050

Russo Spena P, De Maddis M, Lombardi F, Rossini M (2016) Dissimilar resistance spot welding of Q&P and TWIP steel sheets. Mater Manuf Process 31(3):291–299. https://doi.org/10.1080/10426914.2015.1048476

Mai TA, Spowage AC (2004) Characterisation of dissimilar joints in laser welding of steel–kovar, copper–steel and copper–aluminium. Mater Sci Eng A 374(1):224–233. https://doi.org/10.1016/j.msea.2004.02.025

Das A, Butterworth I, Masters I, Williams D (2018) Microstructure and mechanical properties of gap-bridged remote laser welded (RLW) automotive grade AA 5182 joints. Mater Charact 145:697–712. https://doi.org/10.1016/j.matchar.2018.09.035

Briskham P, Blundell N, Han L, Hewitt R, Young K, Boomer D (2006) Comparison of self-pierce riveting, resistance spot welding and spot friction joining for aluminium automotive sheet. SAE Technical Paper,

Li D, Chrysanthou A, Patel I, Williams G (2017) Self-piercing riveting-a review. Int J Adv Manuf Technol 92(5–8):1777–1824

Guo JF, Chen HC, Sun CN, Bi G, Sun Z, Wei J (2014) Friction stir welding of dissimilar materials between AA6061 and AA7075 Al alloys effects of process parameters. Mater Des 56:185–192. https://doi.org/10.1016/j.matdes.2013.10.082

Uzun H, Dalle Donne C, Argagnotto A, Ghidini T, Gambaro C (2005) Friction stir welding of dissimilar Al 6013-T4 to X5CrNi18-10 stainless steel. Mater Des 26(1):41–46. https://doi.org/10.1016/j.matdes.2004.04.002

Faria R, Moura P, Delgado J, de Almeida AT (2012) A sustainability assessment of electric vehicles as a personal mobility system. Energy Convers Manag 61:19–30. https://doi.org/10.1016/j.enconman.2012.02.023

Whittingham MS (2012) History, evolution, and future status of energy storage. Proc IEEE 100:0018–9219

Shawn Lee S, Hyung Kim T, Jack Hu S, Cai WW, Abell JA, Li J (2013) Characterization of joint quality in ultrasonic welding of battery tabs. J Manuf Sci Eng 135 (2):021004–021004–021013. doi:https://doi.org/10.1115/1.4023364

Kong CY, Soar RC, Dickens PM (2005) A model for weld strength in ultrasonically consolidated components. Proc Inst Mech Eng C J Mech Eng Sci 219(1):83–91. https://doi.org/10.1243/095440605X8315

Macwan A, Patel VK, Jiang XQ, Li C, Bhole SD, Chen DL (2014) Ultrasonic spot welding of Al/Mg/Al tri-layered clad sheets. Mater Des 62:344–351. https://doi.org/10.1016/j.matdes.2014.05.035

Ni ZL, Ye FX (2016) Dissimilar joining of aluminum to copper using ultrasonic welding. Mater Manuf Process 31(16):2091–2100. https://doi.org/10.1080/10426914.2016.1221101

Yang J, Cao B, He X, Luo H (2014) Microstructure evolution and mechanical properties of Cu–Al joints by ultrasonic welding. Sci Technol Weld Join 19(6):500–504

Haddadi F, Abu-Farha F (2016) The effect of interface reaction on vibration evolution and performance of aluminium to steel high power ultrasonic spot joints. Mater Des 89:50–57. https://doi.org/10.1016/j.matdes.2015.09.121

Patel VK, Bhole SD, Chen DL (2012) Microstructure and mechanical properties of dissimilar welded Mg–Al joints by ultrasonic spot welding technique. Sci Technol Weld Join 17(3):202–206. https://doi.org/10.1179/1362171811Y.0000000094

Wang SQ, Patel VK, Bhole SD, Wen GD, Chen DL (2015) Microstructure and mechanical properties of ultrasonic spot welded Al/Ti alloy joints. Mater Des 78:33–41. https://doi.org/10.1016/j.matdes.2015.04.023

Macwan A, Chen DL (2015) Microstructure and mechanical properties of ultrasonic spot welded copper-to-magnesium alloy joints. Mater Des 84:261–269. https://doi.org/10.1016/j.matdes.2015.06.104

Janaki Ram GD, Yang Y, Stucker BE (2006) Effect of process parameters on bond formation during ultrasonic consolidation of aluminum alloy 3003. J Manuf Syst 25(3):221–238. https://doi.org/10.1016/S0278-6125(07)80011-2

Kang B, Cai W, Tan C-A (2014) Vibrational energy loss analysis in battery tab ultrasonic welding. J Manuf Process 16(2):218–232. https://doi.org/10.1016/j.jmapro.2013.10.008

Kang B, Cai W, Tan C-A (2014) Dynamic stress analysis of battery tabs under ultrasonic welding. J Manuf Sci Eng 136(4):041011–041011. https://doi.org/10.1115/1.4026990

Lee D, Kannatey-Asibu E, Cai W (2013) Ultrasonic welding simulations for multiple layers of lithium-ion battery tabs. J Manuf Sci Eng 135 (6):061011–061011–061013. doi:https://doi.org/10.1115/1.4025668

Shawn Lee S, Hyung Kim T, Jack Hu S, Cai WW, Abell JA (2015) Analysis of weld formation in multilayer ultrasonic metal welding using high-speed images. J Manuf Sci Eng 137 (3):031016–031016–031018. doi:https://doi.org/10.1115/1.4029787

Design Possibilities for the Chevy Bolt (2015) http://gm-volt.com/2015/06/19/design-possibilities-for-the-chevy-bolt/. Accessed 2017-07-05

Cai W, Blau PJ, Qu J (2013) Friction coefficients of battery metals and the usage in ultrasonic welding simulations. In: 2013 World Electric Vehicle Symposium and Exhibition (EVS27), 17-20 Nov. 2013, pp 1–10. https://doi.org/10.1109/EVS.2013.6914778

Elangovan S, Semeer S, Prakasan K (2009) Temperature and stress distribution in ultrasonic metal welding—an FEA-based study. J Mater Process Technol 209(3):1143–1150. https://doi.org/10.1016/j.jmatprotec.2008.03.032

Zhang C, Li L (2009) A coupled thermal-mechanical analysis of ultrasonic bonding mechanism. Metall Mater Trans B 40(2):196–207. https://doi.org/10.1007/s11663-008-9224-9

Gunduz IE, Ando T, Shattuck E, Wong PY, Doumanidis CC (2005) Enhanced diffusion and phase transformations during ultrasonic welding of zinc and aluminum. Scr Mater 52(9):939–943. https://doi.org/10.1016/j.scriptamat.2004.12.015

Kreye H. Melting phenomena in solid state welding processes

Harthoorn J (1978) Ultrasonic metal welding. Technische Hogeschool Eindhoven

Li J, Han L, Zhong J (2008) Short-circuit diffusion of ultrasonic bonding interfaces in microelectronic packaging. 40 (5):953–957. https://doi.org/10.1002/sia.2840

Montgomery DC (2017) Design and analysis of experiments. John wiley & sons,

Rakić T, Kasagić-Vujanović I, Jovanović M, Jančić-Stojanović B, Ivanović D (2014) Comparison of full factorial design, central composite design, and box-Behnken design in chromatographic method development for the determination of fluconazole and its impurities. Anal Lett 47(8):1334–1347. https://doi.org/10.1080/00032719.2013.867503

Myers RH, Montgomery DC, Anderson-Cook CM (2009) Response surface methodology: process and product optimization using designed experiments, vol 705. John Wiley & Sons,

Alfeld P (1989) Scattered data interpolation in three or more variables A2 - LYCHE, TOM. In: Schumaker LL (ed) Mathematical methods in computer aided geometric design. Academic Press, pp 1–33. https://doi.org/10.1016/B978-0-12-460515-2.50005-6

Fujita K, Kounoe Y (2006) High-order polynomial response surface with optimal selection of interaction terms. In: 11th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference. Multidisciplinary Analysis Optimization Conferences. American Institute of Aeronautics and Astronautics. https://doi.org/10.2514/6.2006-7054

Gencsoy H, Adams J, Shin SJU (1967) On some fundamental problems in ultrasonic welding of dissimilar metals. Weld J 46(4):145-s 5 (4):274

Satpathy MP, Moharana BR, Dewangan S, Sahoo SK (2015) Modeling and optimization of ultrasonic metal welding on dissimilar sheets using fuzzy based genetic algorithm approach. Eng Sci Technol Int J 18(4):634–647. https://doi.org/10.1016/j.jestch.2015.04.007

Satpathy MP, Sahoo SK (2017) Mechanical performance and metallurgical characterization of ultrasonically welded dissimilar joints. J Manuf Process 25:443–451. https://doi.org/10.1016/j.jmapro.2017.01.001

Safavi E, Tarkian M, Gavel H, Ölvander J (2015) Collaborative multidisciplinary design optimization: a framework applied on aircraft conceptual system design. Concurr Eng 23(3):236–249. https://doi.org/10.1177/1063293X15587020

Tiwari A, Hoyos PN, Hutabarat W, Turner C, Ince N, Gan X-P, Prajapat N (2015) Survey on the use of computational optimisation in UK engineering companies. CIRP J Manuf Sci Technol 9:57–68. https://doi.org/10.1016/j.cirpj.2015.01.003

Das A, Franciosa P, Pesce A, Gerbino S (2017) Parametric effect analysis of free-form shape error during sheet metal forming. Int J Eng Sci Technol 9(09S):117–124

Das A, Franciosa P, Gerbino S, Williams D (2016) Prediction of geometric errors of stamped sheet metal parts using deviation field decomposition. In: International conference on competitive manufacturing (COMA), Stellenbosch, South Africa, pp 109–114

Shi X (2011) Design optimization of insulation usage and space conditioning load using energy simulation and genetic algorithm. Energy 36(3):1659–1667. https://doi.org/10.1016/j.energy.2010.12.064

Das A, Franciosa P, Ceglarek D (2015) Fixture design optimisation considering production batch of compliant non-ideal sheet metal parts. Procedia Manuf 1:157–168. https://doi.org/10.1016/j.promfg.2015.09.079

Cicconi P, Germani M, Bondi S, Zuliani A, Cagnacci E (2016) A design methodology to support the optimization of steel structures. Procedia CIRP 50:58–64. https://doi.org/10.1016/j.procir.2016.05.030

Acknowledgements

This research is partially supported by the WMG Centre High Value Manufacturing (HVM) Catapult at The University of Warwick.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Das, A., Masters, I. & Williams, D. Process robustness and strength analysis of multi-layered dissimilar joints using ultrasonic metal welding. Int J Adv Manuf Technol 101, 881–900 (2019). https://doi.org/10.1007/s00170-018-2936-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2936-3