Abstract

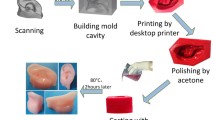

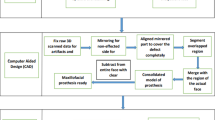

Conventional nasal prosthesis fabrication is highly dependent on the artistic skills of dental technologist. Present manufacturing process is laborious and time consuming. Fast prosthesis fabrication is required for patient with nasal defect to start an early rehabilitation process. This study attempted to explore the feasibility of an affordable FDM-based 3D printer for nasal prosthesis fabrication. Nose model was selected from a digital library followed by mould designing and printing prior to silicone moulding process. With an acceptable aesthetic outcomes and fast production time, the FDM-based 3D printer could be an alternative for indirect nasal prosthesis fabrication.

Similar content being viewed by others

References

Ajay O, Vasunni GK, Nidhin R (2014) Nasal prosthesis –a case report. IOSR J Dent Med Sci 13(6):113–116

Qiu J, Gu XY, Xiong YY, Zhang FQ (2011) Nasal prosthesis rehabilitation using CAD-CAM technology after total rhinectomy: a pilot study. Support Care Cancer 19(7):1055–1059. https://doi.org/10.1007/s00520-011-1157-1

Sun J, Xi J, Chen X, Xiong Y (2011) A CAD/CAM system for fabrication of facial prostheses. Rapid Prototyp J 17(4):253–261. https://doi.org/10.1108/13552541111138379

Ciocca L, Bacci G, Mingucci R, Scotti R (2009) CAD-CAM construction of a provisional nasal prosthesis after ablative tumour surgery of the nose: a pilot case report. Eur J Cancer Care (Engl) 18(1):97–101. https://doi.org/10.1111/j.1365-2354.2008.01013.x

Ciocca L, Fantini M, Crescenzio FD, Persiani F, Scotti R (2010) New protocol for construction of eyeglasses-supported provisional nasal prosthesis using CAD/CAM techniques. J Rehabil Res Dev 47(7):595. https://doi.org/10.1682/jrrd.2009.11.0189

Hutmacher DW, Schantz T, Zein I, Ng KW, Teoh SH, Tan KC (2001) Mechanical properties and cell cultural response of PCL scaffold via fdm.pdf. J Biomed Mater Res 55(2):203–216

Kalita SJ, Bose S, Hosick HL, Bandyopadhyay A (2003) Development of controlled porosity polymer-ceramic composite scaffolds via fused deposition modeling. Mater Sci Eng C Mater Biol Appl 23:611–620

Goyanes A, Buanz AB, Basit AW, Gaisford S (2014) Fused-filament 3D printing (3DP) for fabrication of tablets. Int J Pharm 476(1–2):88–92. https://doi.org/10.1016/j.ijpharm.2014.09.044

Goyanes A, Buanz AB, Hatton GB, Gaisford S, Basit AW (2015) 3D printing of modified-release aminosalicylate (4-ASA and 5-ASA) tablets. Eur J Pharm Biopharm 89:157–162. https://doi.org/10.1016/j.ejpb.2014.12.003

Skowyra J, Pietrzak K, Alhnan MA (2015) Fabrication of extended-release patient-tailored prednisolone tablets via fused deposition modelling (FDM) 3D printing. Eur J Pharm Sci 68:11–17. https://doi.org/10.1016/j.ejps.2014.11.009

Masood SH (2007) Application of fused deposition modelling in controlled drug delivery devices. Assem Autom 27(3):215–221. https://doi.org/10.1108/01445150710763231

Sotsuka Y, Nishimoto S (2014) Making three-dimensional mandible models using a personal three-dimensional printer. J Plast Reconstr Aesthet Surg 67(4):576–578. https://doi.org/10.1016/j.bjps.2013.11.013

Serra T, Capelli C, Toumpaniari R, Orriss IR, Leong JJH, Dalgarno K, Kalaskar DM (2016) Design and fabrication of 3D-printed anatomically shaped lumbar cage for intervertebral disc (IVD) degeneration treatment. Biofabrication 8(3)

Abdullah AM, Rahim TNAT, Hamad WNFW, Mohamad D, Akil HM, Rajion ZA (2018) Mechanical and cytotoxicity properties of hybrid ceramics filled polyamide 12 filament feedstock for craniofacial bone reconstruction via fused deposition modelling. Dent Mater. https://doi.org/10.1016/j.dental.2018.09.006

Rahim TNAT, Abdullah AM, Akil HM, Mohamad D, Rajion ZA (2017) The improvement of mechanical and thermal properties of polyamide 12 3D printed parts by fused deposition modelling. Express Polym Lett 11(12):963–982

Din TNDT, Rajion ZA, Luddin N (2015) Nasofacial morphometric analysis for nasal reconstruction. J Teknol 76(7):81–85

Abdullah AM, Mohamad D, Rahim TNAT, Akil HM, Rajion ZA (2015) 3D printer’s parameter optimization for potential patient specific implant fabrication. J Teknol 76(7):75–79

Abdullah AM, Din TNDT, Mohamad D, Rahim TNAT, Akil HM, Rajion ZA (2016) Surface topography study of prepared 3D printed moulds via 3D printer for silicone elastomer based nasal prosthesis. AIP Conf Proc 1791(1):020013. https://doi.org/10.1063/1.4968868

Tan CY, Akil HM (2012) Impact response of fiber metal laminate sandwich composite structure with polypropylene honeycomb core. Compos Part B 43(3):1433–1438

Ciocca L, Crescenzio FD, Fantini M, Scotti R (2010) Rehabilitation of the nose using CAD/CAM and rapid prototyping technology after ablative surgery of squamous cell carcinoma: a pilot clinical report. Int J Oral Maxillofac Implants 25:808–812

Acknowledgement

The authors greatly acknowledged Mr Mathew Tan from SIRIM Berhad for the assistance on Geomatic Software.

Funding

This study was funded by the USM Research University Team Grant number (1001/PPSG/852004). First author is supported by the USM Fellowship Scheme.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdullah, A.M., Mohamad, D., Din, T.N.D.T. et al. Fabrication of nasal prosthesis utilising an affordable 3D printer. Int J Adv Manuf Technol 100, 1907–1912 (2019). https://doi.org/10.1007/s00170-018-2831-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2831-y