Abstract

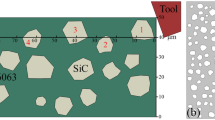

This paper investigates the underlying cutting mechanism of SiC particle-reinforced aluminum matrix composites (MMCs) using finite element (FE) simulations and precision turning experiments. One constitutive model for SiCp/Al composites is established and verified by experiments. On this basis, the possible fracture processes of SiC particles in turning process are studied, and three types of fracture are finally found. The types and the corresponding formation mechanism of machined surface defects are investigated; the relationship between the particle size and surface roughness is established quantitatively. Furthermore, the influences of machining parameters on the cutting force are studied. The proposed FE simulation model and conclusion are verified by precision turning experiments.

Similar content being viewed by others

References

Shen X, Ren S, He X, Qin M, Qu X (2009) Study on methods to strengthen SiC preforms for SiCp/Al composites by pressureless infiltration. J Alloys Compd 468(1):158–163

Dabade UA et al (2007) Surface finish and integrity of machined surfaces on SiCp/Al composites. J Mater Process Technol 192:166–174

Sahin Y (2003) Preparation and some properties of SiC particle reinforced aluminium alloy composites. Mater Des 24(8):671–679

Liu CS et al (2002) Research on the characteristics of the cutting force in the vibration cutting of a particle-reinforced metal matrix composites SiCp/Al. J Mater Process Technol 129.1:196–199

Davim JP, Monteiro Baptista A (2000) Relationship between cutting force and PCD cutting tool wear in machining silicon carbide reinforced aluminium. J Mater Process Technol 103(3):417–423

Dong G et al (2013) Experimental investigation on ultrasonic vibration-assisted turning of SiCp/Al composites. Mater Manuf Process 28(9):999–1002

Bushlya V et al (2017) Performance and wear mechanisms of novel superhard diamond and boron nitride based tools in machining Al-SiCp metal matrix composite. Wear 376:152–164

Dong, Zhigang, et al. (2017) Characterization of material removal in ultrasonically assisted grinding of SiCp/Al with high volume fraction. The International Journal of Advanced Manufacturing Technology : 1–13

Han, Jinjin, et al. (2017) Milling of high volume fraction SiCp/Al composites using PCD tools with different structures of tool edges and grain sizes. The International Journal of Advanced Manufacturing Technology : 1–8

Chen, Xiaolei, et al. (2017) Research on 3D milling simulation of SiCp/Al composite based on a phenomenological model. The International Journal of Advanced Manufacturing Technology: 1–9

Wang T, Xie L, Wang X, Ding Z (2015) PCD tool performance in high-speed milling of high volume fraction SiCp/Al composites. Int J Adv Manuf Technol 78(9):1445–1453

Zhou L, Cui C, Zhang PF, Ma ZY (2017) Finite element and experimental analysis of machinability during machining of high-volume fraction SiCp/Al composites. Int J Adv Manuf Technol 91(5–8):1935–1944

Niu Z, Cheng K (2016) Multiscale multiphysics-based modeling and analysis on the tool wear in micro drilling. Journal of Multiscale Modelling 7.01:1640002

Basheer AC, Dabade UA, Joshi SS, Bhanuprasad VV, Gadre VM (2008) Modeling of surface roughness in precision machining of metal matrix composites using ANN. J Mater Process Technol 197(1):439–444

Wu Q, Si Y, Wang G-S, Wang L (2016) Machinability of a silicon carbide particle-reinforced metal matrix composite. RSC Adv 6(26):21765–21775

Wang T, Xie L, Wang X (2015) Simulation study on defect formation mechanism of the machined surface in milling of high volume fraction SiCp/Al composite. Int J Adv Manuf Technol 79:1185–1194

Zhu Y, Kishawy HA (2005) Influence of alumina particles on the mechanics of machining metal matrix composites[J]. Int J Mach Tool Manu 45(4):389–398

Vogler MP, Devor RE, Kapoor SG et al (2004) On the modeling and analysis of machining performance in micro-endmilling, part I: surface generation[J]. J Manuf Sci Eng 126(4):695–705

Tan Y, Yang D, Sheng Y (2009) Discrete element method (DEM) modeling of fracture and damage in the machining process of polycrystalline SiC[J]. J Eur Ceram Soc 29(6):1029–1037

Tursun G, Weber U, Soppa E, Schmauder S (2006) The influence of transition phases on the damage behaviour of an Al/10vol.%SiC composite[J]. Comput Mater Sci 37(1–2):119–133

Funding

The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (Grant No.51505107), Project (HIT.NSRIF.2017029) supported by Natural Scientific Research Innovation Foundation in Harbin Institute of Technology and the International Science & Technology Cooperation Program of China (No. 2015DFA70630).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Wang, Y., Liao, W., Yang, K. et al. Investigation on cutting mechanism of SiCp/Al composites in precision turning. Int J Adv Manuf Technol 100, 963–972 (2019). https://doi.org/10.1007/s00170-018-2650-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2650-1