Abstract

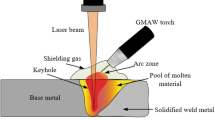

The current investigation aims to scrutinize the impact and fracture toughness of the AH 40 fatigue crack arrester (FCA) steel and its weld metal, when welded with the metal-cored arc welding technique (MCAW). Initially, macroscopic observation and microstructural characterization were carried out in the areas of interest. Subsequently, the impact toughness was determined with the use of the Charpy V-notch test (CVN) at various temperatures, while the values of the absorbed energy (KV), the percentage of shear fracture (PSF), and the lateral expansion (LE) were recorded. Moreover, the ruptured surfaces were examined with a scanning electron microscope (SEM). Finally, the crack tip opening displacement (δ) parameter was estimated at room temperature by fracture toughness testing. The obtained data led to the quantification of the toughness parameters, when dynamic or quasistatic load is applied, while the combined effect of several factors to the degradation of the weld metal toughness was elucidated. The ductile to brittle transition curve and the crack tip opening displacement in the weld metal appeared to be lower than inside the unaffected material. Nevertheless, fracture toughness properties were evaluated within acceptable limits in all cases.

Similar content being viewed by others

References

Billingham J, Sharp JV, Spurrier J, Kilgallon PJ (2003) Review of the performance of high strength steels used offshore. Research Report 105

Coseru A, Capelle J, Pluvinage G (2014) On the use of Charpy transition temperature as reference temperature for the choice of a pipe steel. Eng Fail Anal 37:110–119

ASM International (1996) Fatigue and Fracture, Volume 19. ASM International

Lancaster JF (1999) Metallurgy of Welding. Metallurgy of Welding (Woodhead Publishing Limited). https://doi.org/10.1533/9781845694869

Bhadeshia HKDH, Honeycombe R (2006) Steels: microstructure and properties. Elsevier

Kou S (2003) Metallurgy Second Edition Welding Metallurgy. 822, Wiley

Micromechanisms and the Charpy transition curve, D. François. Book chapter in the book: From Charpy to Impact testing, Editors D. François, A. Pineau, Elsevier, 2002

Siwecki T, Zajac S, Ahlbom B (1992) The influence of thermo-mechanical process parameters on the strength and toughness in direct quenched and tempered boron-steels (Re>700 MPa). In Physical Metallurgy of Direct-Quenched Steels (eds. The Minerals, M. and & (TMS), M. S.) 213–230

Suikkanen P (2009) Development and processing of low carbon bainitic steels

ASM International (2001) Alloying: understanding the basics. ASM International

Shin SY, Hwang B, Kim S, Lee S (2006) Fracture toughness analysis in transition temperature region of API X70 pipeline steels. Mater Sci Eng A 429:196–204

Taillard R, Verrier P, MaurickX T, Foct J (1995) Effect of silicon on CGHAZ toughness and microstructure of microalloyed steel. Metall Mater Trans A 32:75–83

Shim J et al (2001) Effects of Si and Al on acicular ferrite formation in C-Mn steel. Metall Mater Trans A 32:75–83

Seok G et al (2017) Effects of Ni and Mn addition on critical crack tip opening displacement (CTOD) of weld-simulated heat affected zones of three high-strength low alloy (HSLA) steels. Mater Sci Eng A 697:55–65

Totten, G. (2006) Steel heat treatment: metallurgy and technologies. Taylor & Francis

Douglas BA (1981) Nonmetallic inclusions in HSLA steel weldments. DTIC Doc

Ghosh A, Sahoo S, Ghosh M, Ghosh RN, Chakrabarti D (2014) Effect of microstructural parameters, microtexture and matrix strain on the Charpy impact properties of low carbon HSLA steel containing MnS inclusions. Mater Sci Eng A 613:37–47

Cao R, Yuan JJ, Xiao ZG, Ma JY, Mao GJ, Zhang XB, Chen JH (2017) Sources of variability and lower values in toughness measurements of weld metals. J Mater Eng Perform 26:2472–2483

Mirzaei M, Arabi Jeshvaghani R, Yazdipour A, Zangeneh-Madar K (2013) Study of welding velocity and pulse frequency on microstructure and mechanical properties of pulsed gas metal arc welded high strength low alloy steel. Mater Des 51:709–713

Pamnani R, Jayakumar T, Vasudevan M, Sakthivel T (2016) Investigations on the impact toughness of HSLA steel arc welded joints. J Manuf Process 21:75–86

Hashemi SH, Mohammadyani D (2012) Characterisation of weldment hardness, impact energy and microstructure in API X65 steel. Int J Press Vessel Pip 98:8–15

Ju JB, Kim W-S, Jang J-I (2012) Variations in DBTT and CTOD within weld heat-affected zone of API X65 pipeline steel. Mater Sci Eng A 546:258–262

Konda N, Inami A, Arimochi K, Takaoka Y, Lotsberg I (2010) A proposed design S-N curve for steels with improved fatigue resistance (FCA steels). In 11th International Symposium on Practical Design of Ships and Other Floating Structures 1233–1242

Konda, N. et al. (2003) Development of structural steel with superior resistance against fatigue crack growth. In 22nd International Conference on Offshore Mechanics and Arctic Engineering 1–10

Kazasidis ME, Pantelis DI (2017) The effect of the heat input energy on the tensile properties of the AH-40 fatigue crack arrester steel, welded by the use of the robotic metal-cored arc welding technique. Int J Adv Manuf Technol 93:3967–3980. https://doi.org/10.1007/s00170-017-0761-8

Kazasidis M, Chionopoulos S, Pantelis DI (2015) Experimental investigation of FCAW-G weldments of HSLA AH40-FCA (Fatigue Crack Arrester) steel, used in marine applications. In NAV 2015 18th International Conference on Ships and Shipping Research

ASM International (1999) ASM handbook, volume 8, mechanical testing and evaluation

Salimi A, Zadeh HM, Toroghinejad MR, Asefi D, Ansaripour A (2013) Influence of sample direction on the impact toughness of the API-X42 microalloyed steel with a banded structure. Mater Tehnol 47:385–389

Ray A, Paul SK, Jha S (1995) Effect of inclusions and microstructural characteristics on the mechanical properties and fracture behavior of a high-strength low-alloy steel. J Mater Eng Perform 4:679–688

ISO 148: Metallic materials — Charpy pendulum impact test. 2016, (2016)

ISO 12135: Metallic materials — Unified method of test for the determination of quasistatic fracture toughness. 2016, (2016)

Joyce JA (1996) Manual on elastic - plastic fracture: test procedures

DNVGL (2015) Offshore standard: OS-B101: Metallic Materials

DNVGL (2015) Offshore standard: Fabrication and testing of offshore structures

Lee C-H, Shin H-S, Park K-T, Chang K-H (2014) Impact fracture energy of structural steel welds constructed at low ambient temperatures. Constr Build Mater 50:394–400

Bor S(1991) Effect of pearlite banding on mechanical properties of hot-rolled steel plates 31:1445–1446

Shanmugam P, Pathak SD (1996) Some studies on the impact behaviour of banded microalloyed steel. Eng Fract Mech 53:991–1005

Sami Z, Tahar S, Mohamed H (2014) Microstructure and Charpy impact properties of ferrite-martensite dual phase API X70 linepipe steel. Mater Sci Eng A 598:338–342

Study on Impact toughness of C-Mn Multilayer Weld Metal at -60 oC, J.H Chen, T.D. Xia and C. Yan, Welding Research Supplement, January 1993

Shetty MN (2013) Dislocations and mechanical behaviour of materials. PHI Learning Private Limited

Keehan E, Karlsson L, Andren HO (2006) Influence of carbon, manganese and nickel on microstructure and properties of strong steel weld metals: Part 1 – effect of nickel content. Sci Technol Weld Join 11:1–8

Moore, P. & Nicholas, J. (2013) The effect of inclusions on the fracture toughness of local brittle zones in the HAZ of girth welded line pipe. in Proceedings of the ASME 2013 32nd International Conference on Ocean, Offshore and Arctic Engineering

Hwang B, Lee CG, Lee TH (2010) Correlation of microstructure and mechanical properties of thermomechanically processed low-carbon steels containing boron and copper. Metall Mater Trans A Phys Metall Mater Sci 41:85–96

Moura CM, Vilela JJ, Rabello EG, Martins DGP, Carneiro JRG (2009) Evaluation of the ductile-to-brittle transition temperature in steel low carbon. In International Nuclear Atlantic Conference - INAC 2009

ASME (2009) API 579-1/ASME FFS-1 2007 Fitness-For-Service - 2009 Errata

Todinov MT (2001) Estimating the parameters of the impact energy variation in the ductile/brittle transition region from complete and sparse data 21:111–123

Mitigating welding residual stress and distortion, Brust F.W, Kim D.S., book chapter in the book: Processes and mechanisms of welding residual stress and distortion, edited by Zhili Feng, Woodhead Publishing Limited, Cambridge England, 2005

Sreenivasan PR (2006) Charpy energy-lateral expansion relations for a wide range of steels. Int J Press Vessel Pip 83:498–504

Cowan RM (1999) International comparison of impact verification programs. 1–4

Hulka K, Heisterkamp F, Hachtel L (1987) Correlation of processing, microstructure and mechanical properties in 0.03% C–0.10% Nb steel. In Processing, Microstructure and Properties of HSLA Steels (ed. TMS/AIME) 153–167

Gubeljak N (2003) Unstable fracture behaviour of weld metal at high strength low alloy steeel. Mech Autom Control Robot 3:715–727

Acknowledgments

The authors would like to thank the VETA SA company and especially Georgios Poulakis for the assistance and the technical support during the welding procedure. In addition, Voestalpine Böhler Welding Hellas SA is gratefully acknowledged for providing the filler metals.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kazasidis, M.E., Pantelis, D.I., Chatzidouros, E.V. et al. Comparative study of toughness between the AH 40 fatigue crack arrester steel and its weld metal in the case of robotic metal-cored arc welding. Int J Adv Manuf Technol 99, 1183–1194 (2018). https://doi.org/10.1007/s00170-018-2533-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2533-5