Abstract

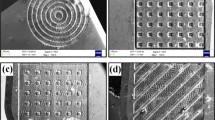

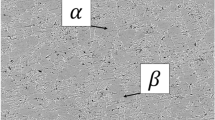

Loss of machining efficiency, part repair, and replacement of mechanical components due to friction and wear is a recurring problem for performance industrial system applications. Recent studies on surface modification and micro-scale texturing have shown successful results in reducing friction and wear of lubricated surfaces. By acting as lubricant reservoirs and wear particle receptacles, micro-scale artificial surface textures positively influence lubrication regimes. In the present experimental study, a Stribeck curve is generated to compare the tribological properties of untextured and textured surfaces created by modulation-assisted machining. Aluminum 6061-T6 disks are mated with high-speed steel pins on a pin-on-disk tribometer configuration for varying speed and texture depth and density. The results suggest that the textured surfaces produced by modulation-assisted machining accelerate the appearance of the elasto-hydrodynamic regime, while also reducing friction by 56% and wear by almost 90%. The enhanced friction and wear reduction were obtained under the lower speeds studied. In general, the disk with shallower dimples presented lower values of friction under the conditions studied. No major differences were found for textures with different dimple densities.

Similar content being viewed by others

References

Holmberg K, Andersson P, Erdemir A (2012) Global energy consumption due to friction in passenger cars. Tribol Int 47:221–234. https://doi.org/10.1016/j.triboint.2011.11.022

Ronen A, Etsion I, Kligerman Y (2001) Friction-reducing surface-texturing in reciprocating automotive components. Tribol Trans 44:359–366. https://doi.org/10.1080/10402000108982468

Akbarzadeh S, Khonsari MM (2010) Effect of surface pattern on Stribeck curve. Tribol Lett 37:477–486. https://doi.org/10.1007/s11249-009-9543-2

Galda L, Pawlus P, Sep J (2009) Dimples shape and distribution effect on characteristics of Stribeck curve. Tribol Int 42:1505–1512. https://doi.org/10.1016/j.triboint.2009.06.001

Kondo Y, Koyama T, Sasaki S (2013) Tribological properties of ionic liquids. Ion Liq New Asp Futur. https://doi.org/10.5772/52595

Bryant M (n.d.) Boundary lubrication. http://www.me.utexas.edu/~bryant/courses/me383s/DownloadFiles/LectureNotes/BoundaryLubrication.pdf

Yin B, Li X, Fu Y, Yun W (2012) Effects of laser textured dimples on the lubrication performances of cylinder liner in diesel engine. Lubr Sci 24:293–312. https://doi.org/10.1002/ls.1185

Vilhena LM, Podgornik B, Vižintin J, Možina J (2011) Influence of texturing parameters and contact conditions on tribological behaviour of laser textured surfaces. Meccanica 46:567–575. https://doi.org/10.1007/s11012-010-9316-x

Podgornik B, Sedlacek M (2012) Performance, characterization and design of textured surfaces. J Tribol 134:041701. https://doi.org/10.1115/1.4007108

Tang W, Zhou Y, Zhu H, Yang H (2013) The effect of surface texturing on reducing the friction and wear of steel under lubricated sliding contact. Appl Surf Sci 273:199–204. https://doi.org/10.1016/j.apsusc.2013.02.013

Costa H, Hutchings I (2015) Some innovative surface texturing techniques for tribological purposes. Proc Inst Mech Eng J J Eng Tribol 229:429–448. https://doi.org/10.1177/1350650114539936

de la Guerra Ochoa E, Otero JE, Tanarro EC, Morgado PL, Lantada AD, Munoz-Guijosa J, Sanz JM (2013) Optimising lubricated friction coefficient by surface texturing. Proc Inst Mech Eng C J Mech Eng Sci 227:2610–2619. https://doi.org/10.1177/0954406213476402

Yuan S, Huang W, Wang X (2011) Orientation effects of micro-grooves on sliding surfaces. Tribol Int 44:1047–1054. https://doi.org/10.1016/j.triboint.2011.04.007

Wos S, Koszela W, Pawlus P (2014) Tribological behaviours of textured surfaces under conformal and non-conformal starved lubricated contact conditions. Proc Inst Mech Eng J J Eng Tribol 229:398–409. https://doi.org/10.1177/1350650114535759

de Kraker A, van Ostayen RAJ, van Beek A, Rixen DJ (2007) A multiscale method modeling surface texture effects. J Tribol 129:221. https://doi.org/10.1115/1.2540156

Gualteri E (2008) Improving tribological properties of steels by surface texturing and coating. 100

Kovalchenko A, Ajayi O, Erdemir A, Fenske G, Etsion I (2004) The effect of laser texturing of steel surfaces and speed-load parameters on the transition of lubrication regime from boundary to hydrodynamic. Tribol Trans 47:299–307. https://doi.org/10.1080/05698190490440902

Gandhi R, Sebastian DG, Basu S, Mann J, Victoria PI, Saldana C (n.d.) Surfaces by vibration/modulation-assisted texturing for tribological applications. Int J Adv Manuf Technol

Kligerman Y, Etsion I, Shinkarenko A (2005) Improving tribological performance of piston rings by partial surface texturing. J Tribol 127:632. https://doi.org/10.1115/1.1866171

Etsion I, Sher E (2009) Improving fuel efficiency with laser surface textured piston rings. Tribol Int 42:542–547. https://doi.org/10.1016/j.triboint.2008.02.015

Etsion I (2005) State of the art in laser surface texturing. J Tribol 127:248. https://doi.org/10.1115/1.1828070

Shinkarenko A, Kligerman Y, Etsion I (2009) The effect of elastomer surface texturing in soft elasto-hydrodynamic lubrication. Tribol Lett 36:95–103. https://doi.org/10.1007/s11249-009-9464-0

Braun D, Greiner C, Schneider J, Gumbsch P (2014) Efficiency of laser surface texturing in the reduction of friction under mixed lubrication. Tribol Int 77:142–147. https://doi.org/10.1016/j.triboint.2014.04.012

Greco A, Raphaelson S, Ehmann K, Wang QJ, Lin C (2009) Surface texturing of tribological interfaces using the vibromechanical texturing method. J Manuf Sci Eng 131:061005. https://doi.org/10.1115/1.4000418

Schneider YG (1984) Formation of surfaces with uniform micropatterns on precision machine and instruments parts. Precis Eng 6:219–225 http://www.sciencedirect.com/science/article/pii/0141635984900072. Accessed October 22, 2015

Iglesias P, Saldana C, Sebastian JD, Gandhi R (2015) Tribological properties of plunging-type textured surfaces produced by modulation-assisted machining, Conf. Proceeding Ibertrib 2015 VIII Iber. Conf Tribol 1 271–277

Yilbas BS, Matthews A, Karatas C, Leyland A, Khaled M, Abu-Dheir N, Al-Aqeeli N, Nie X (2014) Laser texturing of plasma electrolytically oxidized aluminum 6061 surfaces for improved hydrophobicity. J Manuf Sci Eng 136:054501. https://doi.org/10.1115/1.4027977

Aluminum 6061 - T6, ASM Aerosp. Specif. Met. Inc. (n.d.). http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MA6061t6. Accessed July 6, 2016

C. Corporation, Synton Pao 40, 2006. www.chempoint.com/products/download?grade=4774&type=tds

Moore DF (1969) A history of research on surface texture effects. Wear 13:381–412. https://doi.org/10.1016/0043-1648(69)90020-9

Funding

This study received financial support from the Mechanical Engineering Department at the Rochester Institute of Technology and from NSF grants CMMI 1130852 and 1254818.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mehta, P., Liu, R., Mann, J.B. et al. Effect of textured surfaces created by modulation-assisted machining on the Stribeck curve and wear properties of steel-aluminum contact. Int J Adv Manuf Technol 99, 399–409 (2018). https://doi.org/10.1007/s00170-018-2523-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2523-7