Abstract

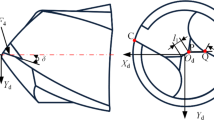

Cross-shaped chisel edge thinning is an effective method to improve the drilling performance of non-coaxial helical flank micro-drill. In order to study the effect of the cross-shaped chisel edge on drilling performance, the mathematical model of cross-shaped chisel edge is proposed. The rake angle, lip inclination angle, uncut chip thickness, and uncut chip width are calculated by MATLAB software. Finite element models of four kinds of micro-drills with a different thinned chisel edge are established using DEFORM-3D software, and micro-drilling simulations on 304 austenitic stainless steel are carried out. The simulation results show that with a decrease in chisel edge length, the drilling force, tool temperature, tool wear, and curl degree of the chip are clearly reduced. However, for micro-drill without chisel edge, the torque and tool temperature are larger than other micro-drills, and string chips are generated during the drilling process. Furthermore, the non-coaxial helical flank micro-drill with an optimal cross-shaped chisel edge is manufactured by a six-axis CNC grinding machine, and the measurement results indicate that the geometrical parameters meet the designed values. At last, the micro-drill with an optimal cross-shaped chisel edge has a satisfactory drilling performance by the micro-drilling experiment.

Similar content being viewed by others

References

Zhang SY, Liang ZQ, Wang XB, Zhou TF, Jiao L, Yan P, Jian HC (2016) Grinding process of helical micro-drill using a six-axis CNC grinding machine and its fundamental drilling performance. Int J Adv Manuf Technol 86(9–12):1–13

Rashed CAA, Romoli L, Tantussi F, Fuso F, Bertoncini L, Fiaschi M, Allegrini M, Din G (2014) Experimental optimization of micro-electrical discharge drilling process from the perspective of inner surface enhancement measured by shear-force microscopy. CIRP J Manuf Sci Technol 7(1):11–19

Romoli L, Rashed CAA, Fiaschi M (2014) Experimental characterization of the inner surface in micro-drilling of spray holes: a comparison between ultrashort pulsed laser and EDM. Opt Laser Technol 56(1):35–42

Olvera DL, Lacalle NLD, Urbikain G, Lamikiz A, Rodal P, Zamakona I (2012) Hole making using ball helical milling on titanium alloys. Mach Sci Technol 16(2):173–188

Nanbu Y, Ochiai K, Ehara K, Matsuda S (2010) High-aspect-ratio microdrilling of the nozzle for gas turbine (2nd report):effect of thinning of microdrill and ultrasonic vibration. Proceedings of JSPE Semestrial Meeting (Vol.2010, pp.1017-1018). The Japan Society for Precision Engineering

Nanbu Y, Ochiai K, Horio K (2011) Influence on rake angle of chisel edge in high-aspect-ratio microdrilling. J Jpn Soc Precis Eng 77:713–717

Lin PD, Tzeng CS (2007) New method for determination of the pose of the grinding wheel for thinning drill points. Int J Mach Tools Manuf 47(15):2218–2229

Wang X, Zheng XH, An QL, Chen M (2012) Experimental investigation on drilling pcb through-holes. Adv Mater Res 426:56–59

Armarego EJA, Zhao H (1996) Predictive force models for point-thinned and circular centre edge twist drill designs. CIRP Ann Manuf Technol 45(1):65–70

Lin C, Kang SK, Ehmann KF (1992) Planar micro-drill point design and grinding methods. Trans N Am Manuf Res Inst SME 20:173–179

Lin C, Kang SK, Ehmann KF (1995) Helical micro-drill point design and grinding. J Eng Ind 117(3):277

Kang SK, Lin C, Ehmann KF (1993) Comparative analysis of planar and helical micro-drill points. Trans NAMRI/SME XXI:189–196

Liang ZQ, Jian HC, Wang XB, Zhao WX, Zhang SY, Yusuke O, Xue SY (2014) A 5-Axis coordinated CNC grinding method for the flank of a non-coaxial helical micro-drill with the cylinder grinding wheel. Adv Mater Res 1017:654–659

Yan L, Jiang F (2013) A practical optimization design of helical geometry drill point and its grinding process. Int J Adv Manuf Technol 64(9–12):1387–1394

Zhang SY, Wang XB, Liang ZQ, Zhou TF, Jiao L, Yan P (2017) Modelling and optimization of the flute profile of micro-drill. Int J Adv Manuf Technol 1–14

Wang JL (1994) Development of new drilling force models for improving drill point geometries. University of Michigan, USA

Funding

This work was supported by National Natural Science Foundation of China (No.51575049), National Basic Research Program of China (No.2015CB059900), and Key Laboratory of Micro-systems and Micro-structures Manufacturing of Ministry of Education, Harbin Institute of Technology (No.2015KM005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, H., Wang, X., Liang, Z. et al. Drilling performance of non-coaxial helical flank micro-drill with cross-shaped chisel edge. Int J Adv Manuf Technol 99, 1301–1311 (2018). https://doi.org/10.1007/s00170-018-2497-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2497-5