Abstract

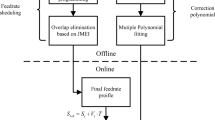

In industrial areas, the machining performance with linear G01 code is a crucial indicator to evaluate the computer numerical control (CNC) systems and many researchers have presented various methods to deal with the corner tracking issue. However, the axis jerk limitations are not satisfied well and the different axis kinematic limitations are not considered in most researches, which will reduce the machining efficiency and machining quality simultaneously. In this paper, a novel method including trajectory planning, feedrate scheduling, and interpolating is proposed to obtain better machining quality and higher machining efficiency. In trajectory planning, a B-spline curve is utilized to smooth the linear toolpath and obtain a curvature-smooth trajectory, which is third-order geometry continuous. Thereby, a time-optimal method for the geometric continuous trajectory is proposed based on linear programming algorithm in the feedrate scheduling and the bounded multi-constraints, including axis velocity, axis acceleration, axis jerk, and feedrate. Moreover, it can be seen that the proposed method is near Bang-bang control. To reduce the computation time of the optimal numerical method, an efficient method with a look-ahead window around the transition B-spline curve is applied. In the interpolation stage, a novel interpolation method about arc-length is proposed to improve computation efficiency. Finally, simulation and experiment are conducted to show superiorities of the proposed method to the already existing approaches. The results show that the cycling time of the proposed method is reduced by more than 7% than G2 method and 20% than G3 method with better contour performance.

Similar content being viewed by others

References

Ye P, Shi C, Yang K, Lv Q (2008) Interpolation of continuous micro line segment trajectories based on look-ahead algorithm in high-speed machining. Int J Adv Manuf Technol 37:881–897. https://doi.org/10.1007/s00170-007-1041-9

Zhang L, Du J (2018) Acceleration smoothing algorithm based on jounce limited for corner motion in high-speed machining. Int J Adv Manuf Technol 95(1–4):1487–1504

Zhang Q, Gao X-S, Li H, Zhao M (2017) Minimum time corner transition algorithm with confined feedrate and axial acceleration for NC machining along linear tool path. Int J Adv Manuf Technol 89:941–956. https://doi.org/10.1007/s00170-016-9144-9

Tajima S, Sencer B (2016) Kinematic corner smoothing for high speed machine tools. Int J Mach Tools Manuf 108:27–43. https://doi.org/10.1016/j.ijmachtools.2016.05.009

Han J, Jiang Y, Tian X, Chen F, Lu C, Xia L (2018) A local smoothing interpolation method for short line segments to realize continuous motion of tool axis acceleration. Int J Adv Manuf Technol 95(5–8):1729–1742

Zhang L, Zhang K, Yan Y (2016) Local corner smoothing transition algorithm based on double cubic NURBS for five-axis linear tool path. Stroj Vestn-J Mech E 62(11):647–656. https://doi.org/10.5545/sv-jme.2016.3525

Jouaneh MK, Wang Z, Dornfeld DA (1990) Trajectory planning for coordinated motion of a robot and a positioning table. Part 1. Path specification. IEEE Trans Robot Autom 6(1990):735–745

Zhao H, Zhu L, Ding H (2013) A real-time look-ahead interpolation methodology with curvature-continuous B-spline transition scheme for CNC machining of short line segments. Int J Mach Tools Manuf 65:88–98. https://doi.org/10.1016/j.ijmachtools.2012.10.005

Erkorkmaz K, Altintas Y (2001) High speed CNC system design. Part I: jerk limited trajectory generation and quintic spline interpolation. Int J Mach Tools Manuf 41(9):1323–1345. https://doi.org/10.1016/S0890-6955(01)00002-5

Du X, Huang J, Zhu L (2017) A locally optimal transition method with analytical calculation of transition length for computer numerical control machining of short line segments. Proc Inst Mech Eng B J Eng Manuf 95440541769735

Sencer B, Ishizaki K, Shamoto E (2015) A curvature optimal sharp corner smoothing algorithm for high-speed feed motion generation of NC systems along linear tool paths. Int J Adv Manuf Technol 76:1977–1992. https://doi.org/10.1007/s00170-014-6386-2

Fan W, Lee C, Chen J (2015) A realtime curvature-smooth interpolation scheme and motion planning for CNC machining of short line segments. Int J Mach Tools Manuf 96:27–46. https://doi.org/10.1016/j.ijmachtools.2015.04.009

Fan W, Lee C, Chen J (2016) Real-time repairable interpolation scheme for CNC tool path processing. Int J Precis Eng Manuf 17:1673–1684. https://doi.org/10.1007/s12541-016-0194-6

Tulsyan S, Altintas Y (2015) Local toolpath smoothing for five-axis machine tools. Int J Mach Tools Manuf 96:15–26. https://doi.org/10.1016/j.ijmachtools.2015.04.014

Zhang Y, Ye P, Wu J, Zhang H (2017) An optimal curvature-smooth transition algorithm with axis jerk limitations along linear segments. Int J Adv Manuf Technol 95(1–4):875–888

Liu H, Liu Q, Yuan S (2017) Adaptive feedrate planning on parametric tool path with geometric and kinematic constraints for CNC machining. Int J Adv Manuf Technol 90(5–8):1889–1896

Zhao M, Chen G, Erkorkmaz K, Gao X-S (2016) Linear programming based feedrate optimization for contour machining of long spline toolpaths. Proc 31th ASPE Annual Mtg, San Diego

Sencer B, Altintas Y, Croft E (2008) Feed optimization for five-axis CNC machine tools with drive constraints. Int J Mach Tools Manuf 48(7–8):733–745

Liang F, Zhao J, Ji S (2017) An iterative feed rate scheduling method with confined high-order constraints in parametric interpolation. Int J Adv Manuf Technol 92(5–8):2001–2015

Lai J, Lin K, Tseng S, Ueng W (2008) On the development of a parametric interpolator with confined chord error, feedrate, acceleration and jerk. Int J Adv Manuf Technol 37:104–121. https://doi.org/10.1007/s00170-007-0954-7

Piegl L, Tiller W (1997) The NURBS book[M]. Springer Verlag, Berlin

Barre P, Bearee R, Borne P, Dumetz E (2005) Influence of a jerk controlled movement law on the vibratory behaviour of high-dynamics systems. J Intell Robot Syst Theory Appl 42:275–293. https://doi.org/10.1007/s10846-004-4002-7

Acknowledgements

We show high respect to the support of the National Key Technology Support Program of China (No. 2015BAI0B16) and would like to express our gratitude to Guangdong ELESY Electric Co. Ltd. The authors are grateful to Dr. Suqin He from Tsinghua University for the technical assistance in Section 4.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Zhao, M., Ye, P. et al. Optimal curvature-smooth transition and efficient feedrate optimization method with axis kinematic limitations for linear toolpath. Int J Adv Manuf Technol 99, 169–179 (2018). https://doi.org/10.1007/s00170-018-2496-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2496-6