Abstract

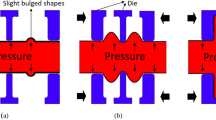

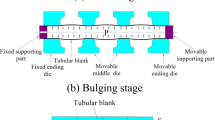

Due to the complicated deformation characteristics of thin-walled bellows with different specifications and its sensitivity to forming parameters in hydroforming (mainly referring to internal pressure), the process may encounter defects, i.e., overthinning, cracking, and wrinkling. To avoid defects and achieve products with high quality, it is a challenge to carry out reliable evaluation of the deformation behaviors of thin-walled bellows induced by the “size effect” with considering the inevitable fluctuation of pressure. In the paper, the hydroforming characteristics (including wall thinning degree and springback) of thin-walled 316-L bellows induced by geometry factors such as inner diameter, wall thickness, convolution width, and convolution height are clarified using finite element (FE) simulations. Meanwhile, deformation characteristics of the bellow considering pressure change are discussed. The numerical simulation results illustrated that the wall thinning degree and springback values of bellows are significantly affected by size factors, and are sensitive to pressure change when decreasing initial wall thickness and increasing convolution height. The results provide a better understanding of the process and a guideline to realize precision forming.

Similar content being viewed by others

References

Sedighi M, Shamsi M (2017) A new approach in producing metal bellows by local arc heating: a parametric study. Int J Adv Manuf Technol 93:3211–3219

Furushima T, Hung NQ, Manabe K, Sasaki O (2013) Development of semi-dieless metal bellows forming process. J Mater Process Technol 213:1406–1411

Si DH, Liu YG, Ma W (2013) Research the influence of curved shape on the multilayer bellows. Appl Mech Mater 303-306:2740–2743

Koç M, Altan T (2001) An overall review of the tube hydroforming (THF) technology. J Mater Process Technol 108(3):384–393

Alaswad A, Benyounis K, Olabi A (2012) Tube hydroforming process: a reference guide. Mater Des 33:328–339

Wei SG, Xu LP, He K, Li JH, Feng W, Du R (2015) Experimental study on manufacturing metal bellows forming by water jet incremental forming. Int J Adv Manuf Technol 81:129–133

Kang BH, Lee MY, Shon SM, Moon YH (2007) Forming various shapes of tubular bellows using a single-step hydroforming process. J Mater Process Technol 194:1–6

Lee SW (2002) Study on the forming parameters of the metal bellows. J Mater Process Technol 130-131:47–53

Liu J, Liu Y, Li LY, Li X, Yang SF, Geng YH, Liu FY (2015) Springback analysis of thin-walled stainless steel bellow in hydroforming. Adv Mater Res 1095:855–858

Alaswad A, Olabi AG, Benyounis KY (2011) Integration of finite element analysis and design of experiments to analyse the geometrical factors in bi-layered tube hydroforming. Mater Des 32:838–850

Li H, Yang H, Zhang ZY, Wang ZK (2013) Size effect related bending formability of thin-walled aluminum alloy tube. Chin J Aeronaut 26(1):230–241

Li H, Yang H, Tian YL, Li GJ, Wang ZH (2012) Geometry-dependent springback behaviors of thin-walled tube upon cold bending. Sci China Tech Sci 55:3469–3482

Bakhshi-Jooybari M, Elyasi M, Gorji A (2010) Numerical and experimental investigation of the effect of the pressure path on forming metallic bellows. Proc IMechE Part B: J Eng Manuf 224:95–101

Zhu Y, Wan M, Zhou YK, Liu QH, Li YC, Zheng NS, Pi KS (2012) Hydroforming of complicated thin-walled circular parts with irregular section by using moving dies. Acta Aeronaut Astronau Sin 5:912–919 (in Chinese)

Faraji G, Besharati MK, Mosavi M, Kashanizadeh H (2008) Experimental and finite element analysis of parameters in manufacturing of metal bellows. Int J Adv Manuf Technol 38:641–648

Faraji G, Mashhadi MM, Norouzifard V (2009) Evaluation of effective parameters in metal bellows forming process. J Mater Process Technol 209:3431–3437

Faraji G, Hashemi R, Mosavi MM, Dizaji AF, Norouzifard V (2010) Hydroforming limits in metal bellows forming process. Mater Manuf Process 25(12):1413–1417

Hashemi R, Faraji G, Abrinia K, Dizaji AF (2010) Application of the hydroforming strain- and stress-limit diagrams to predict necking in metal bellows forming process. Int J Adv Manuf Technol 46:551–561

Hao ZL, Luo SY, Zhao H, Zhang CX, Luo JT (2017) Effect of plate hardening behavior on the deformation of stainless steel metal bellows. J Mater Eng Perform 26(11):5385–5395

Li CS, Huang DB (2005) Metallic materials handbook. Chemical Industry Press, Beijing, pp 40–57 (in Chinese)

Xu KX (1998) Manufacture and application of bellow components. China Machine Press, Beijing, pp 64–70 (in Chinese)

Zhang KF, Wang G, Wang GF, Wang CW, Wu DZ (2004) The superplastic forming technology of Ti-6Al-4V titanium alloys bellows. Mater Sci Forum 447-448:247–252

Li H, Yang H, Zhan M, Sun ZC, Gu RJ (2007) Role of mandrel in NC precision bending process of thin-walled tube. Int J Mach Tool Manu 47:1164–1175

Prasanna Naveen Kumar J, Johns Kumar S, Sarathi Jeyathilak RK, Venkatesh M, Simon Christopher A, Ganesh KC (2017) Effect of design parameters on the static mechanical behaviour of metal bellows using design of experiment and finite element analysis. Int J Interact Des Manuf 11(3):535–545

Expansion Joint Manufacturers Association, Inc. (2008) Standards of the Expansion Joint Manufacturers Association, Inc. 9th edition: 1-11

Acknowledgements

The authors would like to thank the fund of the National Natural Science Foundation of China (No. 51405386), the Natural Science Basic Research Plan in Shaanxi Province of China (No. 2014JQ7237, No. 2017JM5103), the State Key Laboratory of Solidification Processing in NWPU (No. SKLSP201403, No. SKLSP201622), the Young Talent fund of University Association for Science and Technology in Shaanxi, China (No. 20170518), and the Program for Young Innovative Research Team in Xi’an Shiyou University (No. 2015QNKYCXTD02).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, J., Li, H., Liu, Y. et al. “Size effect” related hydroforming characteristics of thin-walled 316-L bellow considering pressure change. Int J Adv Manuf Technol 98, 505–522 (2018). https://doi.org/10.1007/s00170-018-2280-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2280-7