Abstract

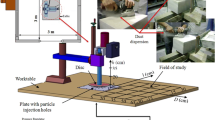

Reducing workers’ exposure to crystalline silica dust is currently a major challenge for granite manufacturing industries. In North America, occupational health regulations are becoming increasingly severe and demanding with respect to quartz dust particle exposure among workers. Of all granite transformation processes, dust control during polishing is the most difficult to realize. During the process, the rotary motion of the tool influences the dust particles, making it harder to capture them. This paper aims to investigate the surface quality, as well as fine particles (FP) and ultrafine particles (UFP) emission and dispersion during dry, rotational and translation-free granite polishing. This research was intended to gather data that could be used to validate dust dispersion simulation results when polishing granite. It was found that workers remain exposed to high concentrations of FP and UFP during this polishing process. In addition, dust particles were found to uniformly contaminate the workspace.

Similar content being viewed by others

References

Steenland K, Ward E (2014) Silica: A lung carcinogen. CA Cancer J Clin 64(1):63–69

Cox LAT Jr (2011) An exposure-response threshold for lung diseases and lung cancer caused by crystalline silica. Risk Anal 31(10):1543–1560

Rushton L (2007) Chronic obstructive pulmonary disease and occupational exposure to silica. Rev Environ Health 22(4):255–272

Rosenberg DM (2000) Silica exposure and silicosis. Am Ceram Soc Bull 79(8):60–62

Kusaka T, Nakayama M, Nakamura K, Ishimiya M, Furusawa E, Ogasawara K (2014) Effect of silica particle size on macrophage inflammatory responses. PLoS One 9(3):e92634

Ahmad I, Khan MI, Patil G (2011) Nanotoxicity of Occupational Dust Generated in Granite Stone Saw Mill. Nanoscience, technology and societal implications (NSTSI), International Conference on, 2011: p. 1–6

Zhang Z, Kleinstreuer C, Donohue JF, Kim CS (2005) Comparison of micro- and nano-size particle depositions in a human upper airway model. J Aerosol Sci 36(2):211–233

Xu XP, Huang H, Li Y (2003) Material removal mechanisms in diamond grinding of granite, part 1: the morphological changes of granite from sawing to grinding. Key Eng Mater 250:215–221

Yavuz H, Ozkahraman T, Demirdag S (2011) Polishing experiments on surface quality of building stone tiles. Constr Build Mater 25(4):1707–1711

Li Y, Huang H, Xu XP (2006) Gloss formation and its relationship with roughness in granite grinding. Key Eng Mater 304-305:413–416

Saidi MN, Songmene V, Kouam J, Bahloul A (2015) Experimental investigation on fine particle emission during granite polishing process. Adv Manuf Technol 81:2109–2121

RSST. Règlement sur la santé et la sécurité du travail. Available from: http://legisquebec.gouv.qc.ca/fr/showdoc/cr/S-2.1,%20r.%2013, Consulted 04–11-2017

Goyer N, Bahloul A, Veillette C (2010) Prévention de l’exposition des travailleurs à la silice, In Guide des bonnes pratiques. IRSST. p. 16

Johnson DL, Phillips ML, Qi C, Van AT, Hawley DA (2017) Experimental evaluation of respirable dust and crystalline silica controls during simulated performance of stone countertop fabrication tasks with powered hand tools. Ann Work Expo Health 61(6):711–723

Akbar-Khanzadeh F, Milz S, Ames A, Susi PP, Bisesi M, Khuder SA, Akbar-Khanzadeh M (2007) Crystalline silica dust and respirable particulate matter during indoor concrete grinding—wet grinding and ventilated grinding compared with uncontrolled conventional grinding. J Occup Environ Hyg 4(10):770–779

Croteau GA, Guffey SE, Flanagan ME, Seixas NS (2002) The effect of local exhaust ventilation controls on dust exposures during concrete cutting and grinding activities. AIHA J (Fairfax, Va) 63(4):458–467

Songmene V, Kouam J, Balhoul A (2018) Effect of minimum quantity lubrication (MQL) on fine and ultrafine particle emission and distribution during polishing of granite. Measurement 114(Supplement C):398–408

Kouam J, Songmene V, Bahloul A (2013) Experimental investigation on PM2.5 particle emission during polishing of granite. Health 05(10):29–35

Yaonan C, Li L, Haiting W, Mingyang W, Yizhi L (2014) Investigations on the dust distribution characteristics of dry milling using inserts with various groove profiles. Adv Manuf Technol 74(1–4):551–562

EKC, Eastman Kodak Company ( 2004) Kodak’s ergonomic design for people at work. 2nd ed. ed. Ergonomic design for people at work. Hoboken, Wiley. 704

Preston FW (1929) The theory and design of plate glass polishing machines. Soc Glass Technol 13(50):111–123

Djebara A (2012) Métrologie des particules ultrafines d'usinage : Optimisation de la caractérisation et de la mesure. Thèse de doctorat, École de technologie supérieure p 148 (In French)

Acknowledgments

This research work is part of a global project on polishing granite (REF 2010-0047) funded by the Institut de Recherche Robert-Sauvé en Santé et Sécurité du Travail (IRSST) entitled ‘Caractérisation et contrôle de la poussière de silice émise par l’opération de polissage à sec et humide dans le secteur de la transformation du granit et autres matériaux contenant du quartz’. The authors also acknowledge A. Lacroix granit (Saint-Boniface, QC, Canada) for donating samples used for experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saidi, M.N., Songmene, V., Kouam, J. et al. Rotational and translation-free polishing of granite: surface quality and dust particles emission and dispersion. Int J Adv Manuf Technol 98, 289–303 (2018). https://doi.org/10.1007/s00170-018-2247-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2247-8