Abstract

Ball screws are robust and economical linear positioning systems widely employed in high-speed and high-precision machines. Due to precision and stability requirements, the preload force is considered one of the main parameters defining the axial stiffness and the maximum axial load of the ball screw feed drives. In high-speed motions, thermal effects are also considerably relevant regarding positioning precision and dynamic stability of the machine. The temperature increase and the thermal gradient between the screw, the balls and the nuts result in geometrical variations and, consequently, variations in the preload force. This paper presents a numerical modelling strategy to predict the preload variation due to temperature increase using a thermo-mechanical 3D finite element method (FEM)-based model for double nut-ball screw drives. Two different thermo-mechanical coupling strategies are compared, and the obtained results are validated with experimental measurements for different initial preload and linear speeds. In the mechanical analysis, the nut-screw ball contact interface, the offset-based preloading and the restrictions of the ball bearings are included in the model, while the thermal analysis considers heat generation and heat diffusion. The causes of the thermal preload variation are discussed considering the ball load distribution and the axial and radial thermal displacements of the contacting points.

Similar content being viewed by others

References

Altintas Y, Verl A, Brecher C, Uriarte L, Pritschow G (2011) Machine tool feed drives. CIRP Ann-Manuf Technol 60(2):779–796

Weule H, Golz H (1991) Preload-control in ball screws — a new approach for machine tool building? CIRP Ann-Manuf Techn 40(1):383–386

ISO 3408-5:2006 (2006) Ball screws. Part 5: Static and dynamic axial load ratings and operational life

Verl A, Frey S, Heinze T (2014) Double nut ball screw with improved operating characteristics. CIRP Ann-Manuf Technol 63(1):361–364

Verl A, Frey S (2010) Correlation between feed velocity and preloading in ball screw drives. CIRP Ann-Manuf Technol 59(1):429–432

Navarro y de Sosa I, Bucht A, Junker T, Pagel K, Drossel W (2014) Novel compensation of axial thermal expansion in ball screw drives. Prod Eng 8(3):397–406

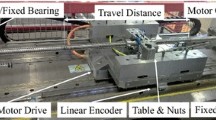

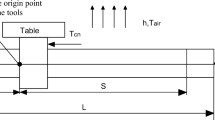

Oyanguren A, Zahn P, Alberdi AH, Larraṅaga J, Lechler A, Ulacia I (2016) Preload variation due to temperature increase in double nut ball screws. Prod Eng 10(4-5):529–537

Carmichael GDT, Davies PB (1970) Measurement of thermally induced preloads in bearings. Strain 6 (4):162–165

Bossmanns B, Tu JF (1999) A thermal model for high speed motorized spindles. Int J Mach Tools Manuf 39(9):1345–1366

Lin CW, Tu JF, Kamman J (2003) An integrated thermo-mechanical-dynamic model to characterize motorized machine tool spindles during very high speed rotation. Int J Mach Tools Manuf 43(10):1035–1050

Takabi J, Khonsari M (2015) On the thermally-induced seizure in bearings: a review. Tribol Int 91:118–130

Mei X, Tsutsumi M, Tao T, Sun N (2003) Study on the load distribution of ball screws with errors. Mech Mach Theory 38(11):1257–1269

Xu S, Sun YF, Shen H (2013) Load distribution of ball screw with contact angle variation. Appl Mech Mater 397-400:435–440

Bertolaso R, Cheikh M, Barranger Y, Duprė J C, Germaneau A, Doumalin P (2014) Experimental and numerical study of the load distribution in a ball-screw system. J Mech Sci Technol 28(4):1411–1420

Li Z, Fan K, Yang J, Zhang Y (2014) Time-varying positioning error modeling and compensation for ball screw systems based on simulation and experimental analysis. Int J Adv Manuf Technol 73(5-8):773–782

Jin C, Wu B, Hu Y (2015) Temperature distribution and thermal error prediction of a cnc feed system under varying operating conditions. Int J Adv Manuf Technol 77(9-12):1979–1992

Shi H, Zhang D, Yang J, Ma C, Mei X, Gong G (2016) Experiment-based thermal error modeling method for dual ball screw feed system of precision machine tool. Int J Adv Manuf Technol 82(9-12):1693–1705

Huang SC (1995) Analysis of a model to forecast thermal deformation of ball screw feed drive systems. Int J Mach Tools Manuf 35(8):1099–1104

Shi H, Ma C, Yang J, Zhao L, Mei X, Gong G (2015) Investigation into effect of thermal expansion on thermally induced error of ball screw feed drive system of precision machine tools. Int J Mach Tools Manuf 97:60–71

Junyong X, Youmin H, Bo W, Tielin S (2009) Research on thermal dynamics characteristics and modeling approach of ball screw. Int J Adv Manuf Technol 43(5-6):421–430

Yun WS, Kim SK, Cho DW (1999) Thermal error analysis for a cnc lathe feed drive system. Int J Mach Tools Manuf 39(7):1087–1101

Fletcher S, Ford D (2003) Measuring and modelling heat transfer and thermal errors on a ballscrew feed drive system, vol 44, chap Laser Metrology and Machine Performance VI, pp 349–359

Xu Z, Liu X, Kim H, Shin J, Lyu S (2011) Thermal error forecast and performance evaluation for an air-cooling ball screw system. Int J Mach Tools Manuf 51(7):605–611

Wu CH, Kung YT (2003) Thermal analysis for the feed drive system of a cnc machine center. Int J Mach Tools Manuf 43(15):1521–1528

Yang A, Chai S, Hsu H, Kuo T, Wu W, Hsieh W, Hwang Y (2013) FEM-based modeling to simulate thermal deformation process for high-speed ball screw drive systems. Appl Mech Mater 481:171–179

Wei CC, Horng J, Lin J (2012) Thermal analysis of a ball-screw system. Adv Mat Res 591-593:818–826

Guo Y, Liu C (2002) Mechanical properties of hardened aisi 52100 steel in hard machining processes. J Manuf Sci E-T ASME 124(1):1–9

Dadalau A, Groh K, Reu M, Verl A (2011) Modeling linear guide systems with cofem: equivalent models for rolling contact. Prod Eng 6(1):39–46

Timoshenko S, Goodier JN (1951) Theory of elasticity. McGraw-Hill, New York

Schaeffler Technical Guide STT (2013) Schaeffler Technologies AG & Co. KG

Bjrling M, Habchi W, Bair S, Larsson R, Marklund P (2013) Towards the true prediction of EHL friction. Tribol Int 66:19–26

Wei C, Lai R (2011) Kinematical analyses and transmission efficiency of a preloaded ball screw operating at high rotational speeds. Mech Mach Theory 46(7):880–898

Bergman TL, Incropera FP (2011) Introduction to heat transfer. Wiley, Hoboken

Morgan VT (1975) The overall convective heat transfer from smooth circular cylinders. Adv Heat Transfer 11:199–264

Madhusudana CV, Madhusudana C (1996) Thermal contact conductance. Springer, Berlin

Acknowledgement

The authors would like to thank the funding of the Basque Government in the predoctoral program (PRE_2016_2_0240). The support of Institut für Steuerungstechnik der Werkzeugmaschinen und Fertigungseinrichtungen (ISW) in the experimental tests, with special mention of P. Zahn, is acknowledged. The technical and financial support of Shuton, S.A. is also greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Oyanguren, A., Larrañaga, J. & Ulacia, I. Thermo-mechanical modelling of ball screw preload force variation in different working conditions. Int J Adv Manuf Technol 97, 723–739 (2018). https://doi.org/10.1007/s00170-018-2008-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2008-8