Abstract

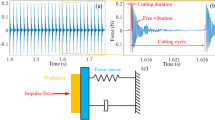

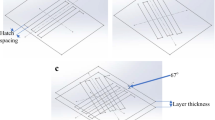

Laser-accelerated metallic flyers can be used in microscale manufacturing processes by providing high-speed impact and shockwave to target materials. This study conducted microscale punching experiments using a laser-accelerated flyer for various mold sizes, workpiece thicknesses, and flyer thicknesses to investigate performance and failure characteristics of the punching process. In the case of a single flyer impact, punching was successful when the ratio of mold diameter to workpiece thickness exceeded 3. High-speed punching advantages, which improve punching quality as the shear zone increases and burrs become smaller, were validated. When flyer thickness was significantly reduced, punching performance deteriorated although higher speed could be realized, because the thinner flyer was difficult to maintain flatness during acceleration, resulting in inefficient forming pressure transfer to the workpiece. When the ratio of mold diameter to workpiece thickness was less than 3, punching was achieved through multiple flyer impacts. However, pressure transfer efficiency from the flyer to the workpiece was further reduced. Thus, punching performance could be improved by reducing the relative size of the flyer to the mold diameter.

Similar content being viewed by others

References

Kim HS (2014) Determination of the tribological size effects in microforming through the scaled upsetting tests of disks. Int J Adv Manuf Tech 75:1253–1261

Fu MW, Chen WL (2013) A review on the state-of-the-art microforming technologies. Int J Adv Manuf Tech 67:2411–2437

Kim HS (2015) A quantitative study of the tribological size effect in microforming with a multi-region FEA. Tribol Int 90:104–109

Murata M, Uede Y, Suzuki H (1995) Punchless punching of thin sheet metal by ultrahigh pressure gas for circular hole. J Mater Process Technol 48:59–10

Joo BY, Oh SI, Jeon BH (2001) Development of micro punching system. CIRP Ann Manuf Technol 50:191–194

Watari H, Ona H, Yoshida Y (2003) Flexible punching method using an elastic tool instead of a metal punch. J Mater Process Technol 137:1151–5, 151

Zhou M, Zhang Y, Cai L (2002) Laser shock forming on coated metal sheets characterized by ultrahigh-strain-rate plastic deformation. J Appl Phys 91:5501–5503

Zhou JZ, Yang JC, Zhang YK, Zhou M (2002) A study on super-speed forming of metal sheet by laser shock waves. J Mater Process Technol 129:241–244

Liu HX, Shen ZB, Wang X, Wang HJ, Tao MK (2010) Numerical simulation and experimentation of a novel micro scale laser high speed punching. Int J Mach Tools Manuf 50:491–494

Wang X, Yuan Y, Shen Z, Gu C, Zhang Q, Liu H (2014) Investigation of the forming pressure and formability of metal foil by laser-driven multi-layered flyer. Opt Laser Technol 58:151–110

Curtis AD, Banishev AA, Shaw WL, Dlott DD (2014) Laser-driven flyer plates for shock compression science: launch and target impact probed by photon Doppler velocimetry. Rev Sci Instrum 85:043908–043901–12

Watson S, Field JE (2000) Integrity of thin, laser-driven flyer plates. J Appl Phys 88:3859–3864

Li JH, Du H, Niu YS, Fu XL (2002) Research of the plastic status parameter and instantaneous clearance of a punching without burr. J Mater Process Technol 129:305–309

Wang X, Shen Z, Gu C, Zhang D, Bu Y, Liu H (2014) Laser indirect shock micro-embossing of commercially pure copper and titanium sheet. Opt Laser Eng 56:74–79

Rodger JA (2014) Application of a fuzzy feasibility Bayesian probabilistic estimation of supply chain backorder aging, unfilled backorders, and customer wait time using stochastic simulation with Markov blankets. Expert Syst Appl 41:7005–7022

Funding

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (Grant NRF-2017R1D1A1B03035818).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

You, JH., Kim, H.S. Formability and fracture of metallic sheet materials in microscale punching processes using laser-accelerated flyer impact. Int J Adv Manuf Technol 96, 3511–3520 (2018). https://doi.org/10.1007/s00170-018-1832-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1832-1