Abstract

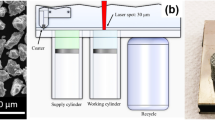

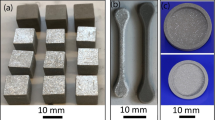

This article presents the results of deploying a new approach for additive manufacturing (AM) functionally graded titanium (Ti) cellular structures with selectively built closed cells, which tailor the mechanical behavior of structures to mimic the similar properties of bones. A hybrid AM system, which combines two methods of binder jetting and material extrusion, was applied. Ti parts were fabricated from powder-bed AM (binder jetting) with encapsulated sacrificial polymeric droplets within the layers and at designated locations to form a periodic pattern. After a heat treatment step, which resulted in the polymer decomposition, the measurement of porosity among the specimens demonstrated the range of 6 to 16% enhancement in these parameters in samples with periodic cells compared to others. Additionally, micro-computerized tomography was performed on the candidate samples to determine the pore morphology and layout within the specimens. The measurement of stiffness and yield stress suggested a range of 2.48 ± 0.37 to 3.55 ± 0.49 GPa and 107.65 ± 18.14 to 145.75 ± 13.85 MPa, respectively. These results suggested that the statistical significance occurred in the batches with periodic cells.

Similar content being viewed by others

References

Gorynin I (1999) Titanium alloys for marine application. Mater Sci Eng A 263(2):112–116

Boyer RR (1996) An overview on the use of titanium in the aerospace industry. Mater Sci Eng A 213(1–2):103–114

Rack HJ, Qazi JI (2006) Titanium alloys for biomedical applications. Mater Sci Eng C 26(8):1269–1277

González JEG, Mirza-Rosca JC (1999) Study of the corrosion behavior of titanium and some of its alloys for biomedical and dental implant applications. J Electroanal Chem 471:109–115

Dabrowski B, Swieszkowski W, Godlinski D, Kurzydlowski KJ (2010) Highly porous titanium scaffolds for orthopaedic applications. J Biomed Mater Res B Appl Biomater 95(1):53–61

Kim TB, Yue S, Zhang Z, Jones E, Jones JR, Lee PD (2014) Additive manufactured porous titanium structures: through-process quantification of pore and strut networks. J Mater Process Technol 214(11):2706–2715

Sheydaeian E, Vlasea M, Woo A, Pilliar R, Hu E, Toyserkani E (2016) Effect of glycerol concentrations on the mechanical properties of additive manufactured porous calcium polyphosphate structures for bone substitute applications. J Biomed Mater Res Part B Appl Biomater https://doi.org/10.1002/jbm.b.33616

Meteyer S, Xu X, Perry N, Zhao YF (2014) Energy and material flow analysis of binder-jetting additive manufacturing processes. Procedia CIRP 15:19–25

Wadley HNG (2002) Cellular metals manufacturing. Adv Eng Mater 4(10):726–733

Ryan G, Pandit A, Apatsidis DP (2006) Fabrication methods of porous metals for use in orthopaedic applications. Biomaterials 27(13):2651–2670

Parthasarathy J, Starly B, Raman S (2011) A design for the additive manufacture of functionally graded porous structures with tailored mechanical properties for biomedical applications. J Manuf Process 13(2):160–170

Basalah A, Shanjani Y, Esmaeili S, Toyserkani E (2012) Characterizations of additive manufactured porous titanium implants. J Biomed Mater Res B Appl Biomater 100 B(7):1970–1979

Butscher A, Bohner M, Hofmann S, Gauckler L, Müller R (2011) Structural and material approaches to bone tissue engineering in powder-based three-dimensional printing. Acta Biomater 7(3):907–920

Vaezi M, Chua CK (2011) Effects of layer thickness and binder saturation level parameters on 3D printing process. Int J Adv Manuf Technol 53:275–284

Y. Toyserkani, E. Vlasea, M. Shanjani. Systems and methods for additive manufacturing of heterogeneous porous structures and structures made therefrom, WO2014110679 A1, 24-Jul-2014

Sheydaeian E, Toyserkani E (2017) A system for selectively encapsulating porogens inside the layers during additive manufacturing: from conceptual design to the first prototype. J Manuf Process 26:330–338

Sheydaeian E, Sarikhani K, Chen P, Toyserkani E (2017) Material process development for the fabrication of heterogeneous titanium structures with selective pore morphology by a hybrid additive manufacturing process. Mater Des 135:142–150

ASTM B311-13 (2013) Standard Test Method for Density of Powder Metallurgy (PM) Materials Containing Less Than Two Percent Porosity. ASTM Int, West Conshohocken, PA https://doi.org/10.1520/B0311-13

ASTM C373 − 14a (2014) Standard Test Method for Water Absorption, Bulk Density, Apparent Porosity, and Apparent Specific Gravity of Fired Whiteware Products, Ceramic Tiles, and Glass Tiles. ASTM Int, West Conshohocken, PA, https://doi.org/10.1520/C0373-14A

Sheydaeian E, Fishman Z, Vlasea M, Toyserkani E (2017) On the effect of throughout layer thickness variation on properties of additively manufactured cellular titanium structures. Addit Manuf 18:40–47

Zhao YY, Fung T, Zhang LP, Zhang FL (2005) Lost carbonate sintering process for manufacturing metal foams. Scr Mater 52(4):295–298

Takemoto M, Fujibayashi S, Neo M, Suzuki J, Kokubo T, Nakamura T (2005) Mechanical properties and osteoconductivity of porous bioactive titanium. Biomaterials 26(30):6014–6023

VlaseaM, Toyserkani E, Pilliar R (2014) Effect of gray scale binder levels on additive manufacturing of porous scaffolds with heterogeneous properties. J of Appl Ceram Technol https://doi.org/10.1111/ijac.12316

Currey JD, Brear K (1990) Hardness, Young’s modulus and yield stress in mammalian mineralized tissues. J Mater Sci Mater Med 1(1):14–20

Esen Z, Bor Ş (2007) Processing of titanium foams using magnesium spacer particles. Scr Mater 56(5):341–344

Dudrová E, Kabátová M (2008) Fractography of sintered iron and steels. Powder Metall Prog 8(2):59–75

Sheydaeian E, Toyserkani E (2018) A new approach for fabrication of titanium-titanium boride periodic composite via additive manufacturing and pressure-less sintering. Compos Part B 138:140–148

Funding

This work is supported by funding from Natural Sciences and Engineering Research Council of Canada (NSERC) and the Federal Economic Development Agency for Southern Ontario (FedDev Ontario).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sheydaeian, E., Toyserkani, E. Additive manufacturing functionally graded titanium structures with selective closed cell layout and controlled morphology. Int J Adv Manuf Technol 96, 3459–3469 (2018). https://doi.org/10.1007/s00170-018-1815-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1815-2