Abstract

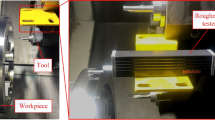

High-speed turning of Inconel 718 was challenged by using TiAlN-coated tungsten carbide tools of positive and negative types, and aluminum-rich (Al, Ti) N-coated ones of negative type. It is found that the (Al, Ti) N negative inserts have much longer tool life than the TiAlN inserts of both the positive and negative types at all the cutting speeds tested. The skirt flank wear was almost the same in mechanism, which was dominated by adhesive wear and abrasive wear for the three types of inserts at the all cutting speeds tested. The cutting edge flank wear changed greatly both in magnitude and in mechanism depending on the type of the insert and the cutting speed. The rake wear was almost limited within the cutting area and at tool life the coatings in the cutting area were all worn off except of the (Al, Ti) N negative inserts tested at the cutting speed of 200 m/min. The hardness of the turned surfaces was always higher than that as received, and the increase in the hardness was greatest for the (Al, Ti) N negative inserts among the three types of the inserts.

Similar content being viewed by others

References

Ezugwu EO, Wang ZM, Machado AR (1998) The machinability of nickel-based alloys: a review. J Mater Process Technol 86:1–16

Dudzinski D, Devillez A, Moufki A, Larrouque’re D, Zerrouki V, Vigneau J (2004) A review of developments towards dry and high speed machining of Inconel 718 alloy. Int J Mach Tools Manuf 44:439–456

Bushlya V, Zhou J, Ståhl JE (2012) Effect of cutting conditions on machinability of superalloy Inconel 718 during high speed turning with coated and uncoated PCBN tools. Proc CIRP 3:370–375

Coelho RT, Silva LR, Braghini A Jr, Bezerra AA (2004) Some effects of cutting edge preparation and geometric modifications when turning INCONEL 718TM at high cutting speeds. J Mater Process Technol 148:147–153

Schulz H (1992) High-speed machining. Ann CIRP 41(2):637–643

Ezugwu EO, Tang SH (1995) Surface abuse when machining cast iron (G-17) and nickel-base superalloy (Inconel 718) with ceramic tools. J Mater Process Technol 55:63–69

Narutaki N, Yamane Y, Hayashi K, Kitagawa T (1993) High speed machining of Inconel 718 with ceramic tools. Ann CIRP 42(1):103–106

Altin A, Nalbant M, Taskesen A (2007) The effects of cutting speed on tool wear and tool life when machining Inconel 718 with ceramic tools. Mater Des 28:2518–2522

Sugihara T, Takemura S, Enomoto T (2016) Study on high-speed machining of Inconel 718 focusing on tool surface topography of CBN cutting tool. Int J Adv Manuf Technol 87:9–17

Jindal PC, Santhanam AT, Schleinkofer U, Shuster AF (1999) Performance of PVD TiN, TiCN and TiAlN coated cemented carbide tools in turning. Int J Refract Met Hard Mater 17:163–170

Zhou M, Makino Y, Nose M, Nogi K (1999) Phase transition and properties of Ti-Al-N thin films prepared by r.f.-plasma assisted magnetron sputtering. Thin Solid Films 339:203–208

Kimura A, Hasegawa H, Yamada K, Suzuki T (2000) Metastable Ti1-xAlxN films with different Al content. J Mater Sci Lett 19:601–602

Prengel HG, Jindal PC, Wendt KH, Santhanam AT, Hedge PL, Penich RM (2001) A new class of high performance PVD coatings for carbide cutting tools. Surf Coat Technol 139:25–34

Bhatt A, Attia H, Vargas R, Thomson V (2010) Wear mechanisms of WC coated and uncoated tools in finish turning of Inconel 718. Tribol Int 43:1113–1121

Kamata Y, Obikawa T (2007) High speed MQL finish-turning of Inconel 718 with different coated tools. J Mater Process Technol 192-193:281–286

Acknowledgements

One of the authors, Mwangi Jessee Njora, would like to thank Japan International Corporation Agency, JICA for their financial support in carrying out this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, B., Njora, M.J. & Sato, Y. High-speed turning of Inconel 718 by using TiAlN- and (Al, Ti) N-coated carbide tools. Int J Adv Manuf Technol 96, 2141–2147 (2018). https://doi.org/10.1007/s00170-018-1765-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1765-8