Abstract

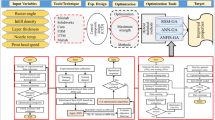

Prediction of surface roughness is a key element for an automated machining center. In this regard, it is important to optimize the machining process. In this paper, fuzzy linear regression approach is employed to predict the surface roughness for a turning process in an uncertain condition. The important process parameters such as cutting speed, cutting depth, speed, and tool tip radius are considered as inputs to determine their significance for prediction. To handle uncertainty, fuzzy theory is employed. Thus, fuzzy liner regression is modeled. To optimize the estimated values of prediction errors, a genetic algorithm (GA) is developed. In addition, tabu search is used to facilitate GA for better performance. A numerical example is worked out to show the effectiveness of the proposed method.

Similar content being viewed by others

References

Zadeh LA (1965) Fuzzy sets. Information and control,( 8, 338–353 ,339–357). Plenum Press, New York

Tanaka H, Vejuoa S, Asai K (1982) Linear aegression analysis with fuzzy model. IEEE Trans Syst Man Cybern 13:903–907

Arabpour AR, Tata M(2008) Estimating the parameters of a fuzzy linear regression model. Iran J Fuzzy Syst, (to appear)

Vijayarani S, Vinupriya M (2015) An efficient algorithm for facial image classiffication. Int J Signal Process Image Process Pattern Recogn 8(11):121–134. https://doi.org/10.14257/ijsip.2015.8.12.13

Jaganathan P, Karthikeyan T (2014) An evolving approach on efficient web crawler using fuzzy genetic algorithm. Int J Sci Res 3(10):156–169

Shankar B, Mishra P, Dehuri S, Kim E, Wang G-N (2016) Techniques and environments for big data analysis: parallel, cloud, and grid computing. Spring 2(5):22–38

Sumathi S, Kumar LA (2016) Computational intelligence paradigms for optimization problems using MATLAB®/SIMULINK®, vol 37. CRC Press, Boca Raton, pp 3201–3217

Cordón O, Herrera F, Gomide F, Hoffmann F and Magdalena L (2001) Ten years of genetic-fuzzy systems: a current framework and new trends. Proceedings of Joint 9th IFSA World Congress and 20th NAFIPS International Conference. Vancouver, Canada, pp 1241–1246

Park YW, Rhee S (2008) Process modeling and parameter optimization using neural network and genetic algorithms for aluminum laser welding automation. Int J Adv Manuf Technol 37(9-10):1014–1021. https://doi.org/10.1007/s00170-007-1039-3

Jiao Y, Lei S, Pei ZJ, Lee ES (2004) Fuzzy adaptive networks in machining process modeling: surface roughness prediction for turning operations. Int J Mach Tools Manuf 47:375–386

Cococcioni M, Lazzerini B, Marcelloni F (2011) On reducing computational overhead in multi-objective genetic Takagi-Sugeno fuzzy systems. Appl Soft Comput 11(1):675–688. https://doi.org/10.1016/j.asoc.2009.12.028

Bastian A (2000) Identifying fuzzy models utilizing genetic programming. Fuzzy Sets Syst 113(3):333–350. https://doi.org/10.1016/S0165-0114(98)00086-4

Glover F, Laguna M (2013) Tabu search. Handbook of Combinatorial Optimization. pp 3261–3362. https://doi.org/10.1007/978-1-4419-7997-1_17

Asilturk I, Cunkas M (2011) Modeling and prediction of surface roughness in turning operations using artificial neural network and multiple regression method. Expert Syst Appl 38(5):5826–5832. https://doi.org/10.1016/j.eswa.2010.11.041

Hessainia Z, Belbah A, Yallese MA (2013) On the prediction of surface roughness in the hard turning based on cutting parameters and tool vibrations. Measurement 46:1671–1681

Chauhan P, Pant M, Deep K (2015) Parameter optimization of multi-pass turning using chaotic PSO. Int J Mach Learn Cybern 6(2):319–337

Nataraj M, Balasubramanian K (2016) Parametric optimization of CNC turning process for hybrid metal matrix composite. Int J Adv Manuf Technol 1–10

Yildiz AR (2012) A comparative study of population-based optimization algorithms for turning operations. Inf Sci 210(22):81–88. https://doi.org/10.1016/j.ins.2012.03.005

Zain AM, Haron H, Sharif S (2010) Application of GA to optimize cutting conditions for minimizing surface roughness in end milling machining process. Expert Syst Appl 37(6):4650–4659. https://doi.org/10.1016/j.eswa.2009.12.043

Rajasekaran T, Palanikumar K, Vinayagam BK (2011) Application of fuzzy logic for modeling surface roughness in turning CFRP composites using CBN tool. Prod Eng 5(2):191–199. https://doi.org/10.1007/s11740-011-0297-y

Kolahan F, Khajavi A (2010) A statistical approach for predicting and optimizing depth of cut in A W J machining for 6063-T6 Al alloy. Int J Mech Syst Sci Eng 2(2):143–146

Hu P, Zhang M, Jin M, Yao B (2014) A support vector machine with the tabu search algorithm for freeway incident detection. Int J Appl Math Comput Sci 2014–06-26. https://doi.org/10.2478/amcs-2014-0030

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gholizadeh, H., Javadian, N. & Fazlollahtabar, H. Fuzzy regression integrated with genetic-tabu algorithm for prediction and optimization of a turning process. Int J Adv Manuf Technol 96, 2781–2790 (2018). https://doi.org/10.1007/s00170-018-1655-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1655-0