Abstract

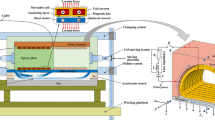

In this study, the dimensional accuracy of metallic bipolar plates with stainless steel 316 was investigated in diagonal, longitudinal, and transverse direction (directional dimensional accuracy). The results showed that directional dimensional accuracy (uniformity of channel depth) would increase by raising the applied force. In addition, increasing the rubber hardness and rubber thickness leads to higher directional dimensional accuracy. After that, the dimensional accuracy in constant direction (total dimensional accuracy) was investigated. According to the result, central channels have lower channel’s depth than lateral channels. Difference between central and lateral channel’s depth was decreased when the applied force was increased. Also, total dimensional accuracy increased by increasing hardness and thickness of rubber. Most accurate bipolar plate is fabricated by 450 kN applied force and rubbers with hardness of Shore A 90 and 30 mm thickness. However, dimensional accuracy in conventional rubber forming process was not satisfying. Thus, a new method was used in order to improve the dimensional accuracy of fabricated bipolar plates named semi-stamp rubber forming. The results indicated that using semi-stamp rubber forming instead of conventional rubber forming would lead to 8.35, 3.72, and 3.3% improvement in directional dimensional accuracy and also 1.075% improvement in total dimensional accuracy.

Similar content being viewed by others

References

Carrette L, Friedrich K, Stimming U (2001) Fuel cells-fundamentals and applications. Fuel Cells 1(1):5–39. https://doi.org/10.1002/1615-6854(200105)1:1<5::AID-FUCE5>3.0.CO;2-G

Ruiu T, Dreizler AM, Mitzel J, Gülzow E (2016) Evaluation of a 2.5 kWel automotive low temperature PEM fuel cell stack with extended operating temperature range up to 120 °C. J Power Sources 303:257–266. https://doi.org/10.1016/j.jpowsour.2015.10.056

Holland B, Zhu J, Jamet L (2001) Fuel cell technology and application. J Power Sources 100:171–187

EG & G Technical Services, Inc. Science Applications International Corporation (2002) Fuel Cell Handbook, 6th edn. U.S. Department of Energy, Morgantown

Yao K, Karan K, McAuley K, Oosthuizen P, Peppley B, Xie T (2004) A review of mathematical models for hydrogen and direct methanol polymer electrolyte membrane fuel cells. Fuel Cells 4(12):3–29. https://doi.org/10.1002/fuce.200300004

Silva RF, Franchi D, Leone A, Pilloni L, Masci A, Pozio A (2006) Surface conductivity and stability of metallic bipolar plate materials for polymer electrolyte fuel cells. Electrochim Acta 51:3592–3598. https://doi.org/10.1016/j.electacta.2005.10.015

Li M, Lou S, Zeng C, Shen J, Lin H, Cao C (2004) Corrosion behavior of TiN coated type 316 stainless steel in simulated PEMFC environments. Corros Sci 46(6):1369–1380. https://doi.org/10.1016/S0010-938X(03)00187-2

Kumagai M, Myung ST, Kuwata S, Asaishi R, Yashiro H (2008) Corrosion behavior of austenitic stainless steels as a function of pH for use as bipolar plates in polymer electrolyte membrane fuel cells. Electrochim Acta 52:4205–4212

Yan X, Hou M, Zhang H, Jing F, Ming P, Yi B (2006) Performance of PEMFC stack using expanded graphite bipolar plates. J Power Sources 160:242–257

Minke C, Hickmann T, dos Santos AR, Kunz U, Turek T (2016) Cost and performance prospects for composite bipolar plates in fuel cells and redox flow batteries. J Power Sources 160:182–190

Hung JC, Chang DH, Chuang Y (2012) The fabrication of high-aspect-ratio micro-flow channels on metallic bipolar plates using die-sinking micro-electrical discharge machining. J Power Sources 198:158–163. https://doi.org/10.1016/j.jpowsour.2011.09.065

Lim SS, Kim YT, Kang CG (2013) Fabrication of aluminum1050 micro-channel proton exchange membrane fuel cell bipolar plate using rubber-pad-forming process. Int J Adv Manuf Technol 65(1-4):231–238. https://doi.org/10.1007/s00170-012-4162-8

Wang SH, Peng J, Lui WB, Zhang JS (2006) Performance of the gold-plated titanium bipolar plates for the light weight PEM fuel cells. J Power Sources 162(1):486–491. https://doi.org/10.1016/j.jpowsour.2006.06.084

Lee SJ, Lai JJ, Huang CH (2005) Stainless steel bipolar plates. J Power Sources 145(2):362–368. https://doi.org/10.1016/j.jpowsour.2005.01.082

Davies DP, Adcock PL, Turpin M, Rowen SJ (2000) Stainless steel as a bipolar plate material for solid polymer fuel cells. J Power Sources 86(1-2):237–242. https://doi.org/10.1016/S0378-7753(99)00524-8

Jeon DH, Greenway S, Shimpalee S, Van Zee JW (2008) The effect of serpentine flow-field designs on PEM fuel cell performance. Int J Hydrog Energy 33(3):1052–1066. https://doi.org/10.1016/j.ijhydene.2007.11.015

Jin CK, Koo JY, Kang CG (2014) Fabrication of stainless steel bipolar plates for fuel cells using dynamic loads for the stamping process and performance evaluation of a single cell. Int J Hydrog Energy 39(36):21461–21469. https://doi.org/10.1016/j.ijhydene.2014.04.103

Hung JC, Yang TC, Li KC (2011) Studies on the fabrication of metallic bipolar plates-using micro electrical discharge machining milling. J Power Sources 196(4):2070–2074. https://doi.org/10.1016/j.jpowsour.2010.10.001

Koç M, Mahabunphachai S (2007) Feasibility investigations on a novel micro-manufacturing process for fabrication of fuel cell bipolar plates: internal pressure-assisted embossing of micro-channels with in-die mechanical bonding. J Power Sources 172(2):725–733. https://doi.org/10.1016/j.jpowsour.2007.05.089

Lee SJ, Chen YP, Huang CH (2005) Electroforming of metallic bipolar plates with micro-featured flow field. J Power Sources 145(2):369–375. https://doi.org/10.1016/j.jpowsour.2004.12.072

Jin CK, Jeong MG, Kang CG (2014) Fabrication of titanium bipolar plates by rubber forming and performance of single cell using TiN-coated titanium bipolar plates. Int J Hydrog Energy 39(36):21480–21488. https://doi.org/10.1016/j.ijhydene.2014.03.013

Liu Y, Hua L, Lan J, Wei X (2010) Studies of the deformation styles of the rubber-pad forming process used for manufacturing metallic bipolar plates. J Power Sources 195(24):8177–8184. https://doi.org/10.1016/j.jpowsour.2010.06.078

Kolahdooz R, Asghari S, Rashid-Nadimi S, Amirfazli A (2017) Integration of finite element analysis and design of experiment for the investigation of critical factors in rubber pad forming of metallic bipolar plates for PEM fuel cells. Int J Hydrog Energy 42(1):575–589. https://doi.org/10.1016/j.ijhydene.2016.11.020

Elyasi M, Ghadikolaee HT, Hosseinzadeh M (2017) Fabrication of metallic bipolar plates in PEM fuel cell using semi-stamp rubber forming process. Int J Adv Manuf Technol 92(1-4):765–776. https://doi.org/10.1007/s00170-017-0206-4

Elyasi M, Khatir FA, Hosseinzadeh M (2017) Manufacturing metallic bipolar plate fuel cells through rubber pad forming process. Int J Adv Manuf Technol 89(9-12):3257–3269. https://doi.org/10.1007/s00170-016-9297-6

Manso AP, Marzo FF, Barranco J, Garikano X, Garmendia Mujika M (2012) Influence of geometric parameters of the flow fields on the performance of a PEM fuel cell. A review. Int J Hydrog Energy 37(20):15256–15287. https://doi.org/10.1016/j.ijhydene.2012.07.076

Shimpalee S, Lilavivat V, Van Zee JW, McCrabb H, Lozano-Morales A (2011) Understanding the effect of channel tolerances on performance of PEMFCs. Int J Hydrog Energy 36(19):12512–12523. https://doi.org/10.1016/j.ijhydene.2011.06.146

Taccani R, Zuliani N (2011) Effect of flow field design on performances of high temperature PEM fuel cells: experimental analysis. Int J Hydrog Energy 36:282–287

Liu Y, Hua L (2010) Fabrication of metallic bipolar plate for proton exchange membrane fuel cell by rubber pad forming. J Power Sources 195(11):3529–3535. https://doi.org/10.1016/j.jpowsour.2009.12.046

Yi P, Peng L, Lai X, Ni J (2011) A numerical model for predicting gas diffusion layer failure in proton exchange membrane fuel cells. J Fuel Cell Sci Technol 8:1–10

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Elyasi, M., Ghadikolaee, H.T. & Hosseinzadeh, M. Investigation of dimensional accuracy in forming of metallic bipolar plates with serpentine flow field. Int J Adv Manuf Technol 96, 1045–1060 (2018). https://doi.org/10.1007/s00170-018-1650-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-1650-5