Abstract

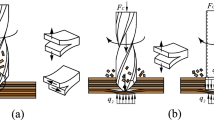

During the research on high-quality hole drilling technology for glass fiber–reinforced polymer (GFRP), more and more researchers have discovered and focused on the coupling effect between the machining parameters on the damage at the hole exit. Most of them have verified and described this phenomenon by mathematical statistics, but there is no further analysis for its mechanism. In this paper, a set of orthogonal experiments were conducted to investigate the coupling effect between the clearance angles of outer cutting edges, the spindle speed, and the feed speed when drilling the GFRP materials with candlestick drills. Through the experimental results shown by the response surface, the influencing factors of the exit damage were divided into the pushing effect, cutting effect, and the physical properties of the material according to the special damage formation process. It was found that the reason for the coupling effect of the machining and tool parameters was that the change of these parameters would have different effect on the pushing, cutting, and physical properties of the materials at the same time. In addition, the optimal machining parameters for each candlestick drill were also given according to the experimental results.

Similar content being viewed by others

References

Ho-Cheng H, Dharan CKH (1990) Delamination during drilling in composite laminates. J Eng Ind 112(3):236–239

Gao C, Xiao J, Xu J, Ke Y (2016) Factor analysis of machining parameters of fiber-reinforced polymer composites based on finite element simulation with experimental investigation. Int J Adv Manuf Technol 83(5–8):1113–1125

Nightingale C, Day RJ (2002) Flexural and interlaminar shear strength properties of carbon fibre/epoxy composites cured thermally and with microwave radiation. Compos A: Appl Sci Manuf 33(7):1021–1030

Hocheng H, Tsao CC (2003) Comprehensive analysis of delamination in drilling of composite materials with various drill bits. J Mater Process Technol 140(1–3):335–339

Gaitonde VN, Karnik SR, Rubio JC, Correia AE, Abrão AM, Davim JP (2008) Analysis of parametric influence on delamination in high-speed drilling of carbon fiber reinforced plastic composites. J Mater Process Technol 203(1):431–438

Grilo TJ, Paulo RMF, Silva CRM, Davim JP (2013) Experimental delamination analyses of CFRPS using different drill geometries. Compos Part B Eng 45(1):1344–1350

Liu LP, Qi CL, Wu F, Xu JX, Zhu XM (2017) Experimental thrust forces and delamination analysis of GFRP laminates using candlestick drills. Mater Manuf Process 33(6):695–708

Liu L, Qi C, Wu F, Zhang X, Zhu X (2017) Analysis of thrust force and delamination in drilling GFRP composites with candle stick drills. Int J Adv Manuf Technol 95(3):1–16

Dipaolo G, Kapoor SG, Devor RE (1993) An experimental investigation of the crack growth phenomenon for drilling of fiber-reinforced composite materials. J Eng Ind 118(1):104–110

Davim JP, Reis P (2003) Drilling carbon fiber reinforced plastics manufactured by autoclave—experimental and statistical study. Mater Des 24(5):315–324

Davim JP, Reis P, Antonio CC (2004) Experimental study of drilling glass fiber reinforced plastics (GFRP) manufactured by hand lay-up. Compos Sci Technol 64(2):289–297

Karnik SR, Gaitonde VN, Rubio JC, Correia AE, Abrão AM, Davim JP (2008) Delamination analysis in high speed drilling of carbon fiber reinforced plastics (CFRP) using artificial neural network model. Mater Des 29(9):1768–1776

Rubio JC, Abrao AM, Faria PE, Correia AE, Davim JP (2008) Effects of high speed in the drilling of glass fibre reinforced plastic: evaluation of the delamination factor. Int J Mach Tool Manu 48(6):715–720

Krishnamoorthy A, Boopathy SR, Palanikumar K (2009) Delamination analysis in drilling of CFRP composites using response surface methodology. J Compos Mater 43(24):2885–2902

Foreman JP, Porter D, Behzadi S, Curtis PT, Jones FR (2010) Predicting the thermomechanical properties of an epoxy resin blend as a function of temperature and strain rate. Compos A: Appl Sci Manuf 41(9):1072–1076

Weiss RE (1977) The effect of drilling temperature on multilayer board hole quality. Circuit World 3(3):8–14

Koplev A, Lystrup A, Vorm T (1983) The cutting process, chips, and cutting forces in machining CFRP. Compo 14(4):371–376

Xu J, An Q, Chen M (2015) An experimental investigation on cutting-induced damage when drilling high-strength T800S/250F carbon fiber-reinforced polymer. P I Mech Eng B-J Eng 231(11):1931–1940

Liu L, Wu F, Qi C, Liu T, Tian J (2018) High frequency vibration analysis in drilling of GFRP laminates using candlestick drills. Compos Struct 184:742–758

Velayudham A, Krishnamurthy R (2007) Effect of point geometry and their influence on thrust and delamination in drilling of polymeric composites. J Mater Process Technol 185(1–3):204–209

Mallick PK (1988) Fiber-reinforced composites :: materials, manufacturing, and design. Marcel Dekker, New York

Wen Q, Gao H, Zhao D, Guo D M (2011) Drilling C/E composites with electroplated diamond abrasive tool and its damage evaluation method. Key Eng Mater 487(5):371–375

Vasiliev VV, Morozov EV (2001) Mechanics and analysis of composite materials. Elsevier, Oxford

El-Sonbaty I, Khashaba UA, Machaly T (2004) Factors affecting the machinability of GFR/epoxy composites. Compos Struct 63(3–4):329–338

Yashiro T, Ogawa T, Sasahara H (2013) Temperature measurement of cutting tool and machined surface layer in milling of CFRP. Int J Mach Tool Manu 70:63–69

Chatterjee A (2009) Thermal degradation analysis of thermoset resins. J Appl Polym Sci 114(3):1417–1425

Sorrentino L, Turchetta S, Bellini C (2017) In process monitoring of cutting temperature during the drilling of FRP laminate. Compos Struct 168:549–561

Abukhshim NA, Mativenga PT, Sheikh MA (2006) Heat generation and temperature prediction in metal cutting: a review and implications for high speed machining. Int J Mach Tool Manu 46(7–8):782–800

Longbottom JM, Lanham JD (2005) Cutting temperature measurement while machining–a review. Aircr Eng Aerosp Technol 77(2):122–130

Jing X, Zhang D, Wang Z, Li G (2009) Investigations of tool geometry in ultraprecision cutting: a FEM simulation approach. In Mechatronics and Automation, 2009. ICMA 2009. International Conference on (pp. 5099–5104). IEEE

Henerichs M, Voss R, Kuster F, Wegener K (2015) Machining of carbon fiber reinforced plastics: Influence of tool geometry and fiber orientation on the machining forces CIRP. J Manu Sci Technol 9:136–145

Weinert K, Kempmann C (2004) Cutting temperatures and their effects on the machining behaviour in drilling reinforced plastic composites. Adv Eng Mater 6(8):684–689

Rajamurugan TV, Shanmugam K, Palanikumar K (2013) Analysis of delamination in drilling glass fiber reinforced polyester composites. Mater Des 45:80–87

Davim JP, Reis P (2003) Study of delamination in drilling carbon fiber reinforced plastics (CFRP) using design experiments. Compos Struct 59(4):481–487

Sardiñas RQ, Reis P, Davim JP (2006) Multi-objective optimization of cutting parameters for drilling laminate composite materials by using genetic algorithms. Compos Sci Technol 66(15):3083–3088

Funding

This project obtained designated funds from the National Natural Science Foundation (No. 51405491, No. 51605331), and Basic Scientific Research Foundation of Central University (No. 3122017028).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tian, J., Wu, F., Zhang, P. et al. The coupling effect and damage analysis when drilling GFRP laminates using candlestick drills. Int J Adv Manuf Technol 102, 519–531 (2019). https://doi.org/10.1007/s00170-018-03216-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-03216-6