Abstract

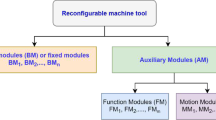

Reconfigurable manufacturing systems constitute a new manufacturing paradigm and are considered as the future of manufacturing because of their changeable and flexible nature. In a reconfigurable manufacturing environment, basic modules can be rearranged, interchanged, or modified, to adjust the production capacity according to production requirements. Reconfigurable machine tools have modular structure comprising of basic and auxiliary modules that aid in modifying the functionality of a manufacturing system. As the product’s design and its manufacturing capabilities are closely related, the manufacturing system is desired to be customizable to cater for all the design changes. Moreover, the performance of a manufacturing system lies in a set of planning and scheduling data incorporated with the machining capabilities keeping in view the market demands. This research work is based on the co-evolution of process planning and machine configurations in which optimal machine capabilities are generated through the application of multi-objective genetic algorithms. Furthermore, based on these capabilities, the system is tested for reconfiguration in case of production changeovers. Since, in a reconfigurable environment, the same machine can be used to perform different tasks depending on the required configuration, the subject research work assigns optimum number of machines by minimizing the machining capabilities to carry out different operations in order to streamline production responses. An algorithm has also been developed and verified on a part family. As a result of the proposed methodology, an optimized reconfigurable framework can be achieved to realize optimal production of a part family. Finally, the proposed methodology was applied on a case study and respective conclusions were drawn.

Similar content being viewed by others

References

Meghrabi MG, Ulsoy AG, Koren Y (2000) Reconfigurable manufacturing system: key to future manufacturing. J Intell Manuf 11:403–419

Meghrabi MG, Ulsoy AG, Koren Y, Heytler P (2002) Trends and perspectives in flexible and reconfigurable manufacturing system. J Intell Manuf 13:135–146

Rakesh K, Jain PK, Mehta NK (2010) A framework for simultaneous recognition of driving part families and operation groups for driving a reconfigurable system. Adv Prod Eng Manag 5:45–58

ElMaraghy HA (2006) Flexible and manufacturing system paradigms. Int J Flex Manuf Syst 17:261–276

Mulubika C (2013) Evaluation of control strategies for reconfigurable manufacturing systems. MScEng thesis, Stellenbosh University, South Africa

Liraviasl KK (2015) A capacity planning simulation model for reconfigurable manufacturing systems. MASc thesis, University of Windsor, Ontario, Canada

Wiendahl HP, ElMaraghy HA, Nyhuis P, Zah MF, Wiendahl HH, Duffie N, Brieke M (2007) Changeable manufacturing—classification, design and operation. CIRP Ann Manuf Technol 56(2):783–809. https://doi.org/10.1016/j.cirp.2007.10.003

Tolio T, Ceglarek D, ElMaraghy HA, Fischer A, SJ H, Laperriere L, Newman ST (2010) SPECIES—co-evolution of products, processes and production systems. CIRP Ann Manuf Technol 59(2):672–693

Wang GX, Huang SH, Yan Y, JJ D (2016) Reconfiguration schemes evaluation based on preference ranking of key characteristics of reconfigurable manufacturing systems. Int J Adv Manuf Technol 89:2231–2249

Wang W, Koren Y (2012) Scalability planning for reconfigurable manufacturing system. J Manuf Syst 31(2):83–91. https://doi.org/10.1016/j.jmsy.2011.11.001

Lateef-Ur-Rehman AUR (2012) Manufacturing configuration selection using multicriteria decision tool. Int J Adv Manuf Technol 65:625–639

Azab A, ElMaraghy H, Nyhuis P, Pachow-Frauenhofer J, Schmidt M (2013) Mechanics of change: a framework to reconfigure manufacturing systems. CIRP J Manuf Sci Technol 6(2):110–119. https://doi.org/10.1016/j.cirpj.2012.12.002

Zahid T (2013) Multi criteria optimization of process plans for reconfigurable manufacturing system: an evolutionary approach. International Mechanical Engineering Congress and Exposition, ISBN: 978-0-7918-5619-2

Prasad D, Jayswal SC (2017) Reconfigurability consideration and scheduling of products in a manufacturing industry. Int J Prod Res 1–20

Hees A, Reinhart G (2015) Approach for production planning in reconfigurable manufacturing systems. Procedia CIRP 33:70–75. https://doi.org/10.1016/j.procir.2015.06.014

Zhao F, Murray VR, Ramani K, Sutherland JW (2012) Toward the development of process plans with reduced environmental impacts. Front Mech Eng 7(3):231–246. https://doi.org/10.1007/s11465-012-0334-3

Azab A, ElMaraghy HA (2007) Mathematical modeling for reconfigurable process planning. CIRP Ann Manuf Technol 56(1):467–472

ElMaraghy HA (2009) Changeable and reconfigurable manufacturing systems. Springer Series in Advanced Manufacturing, ISBN: 978-1-84882-067-8

Koren Y, Wang W, Gu X (2017) Value creation through design for scalability of reconfigurable manufacturing systems. Int J Prod Res 55(5):1227–1242. https://doi.org/10.1080/00207543.2016.1145821

Koren Y (2006) General RMS characteristics, comparison with dedicated and flexible systems. Reconfigurable manufacturing systems and transformable factories. 3:27–45

Koren Y, Ulsoy AG (2002) Vision, principles and impact of reconfigurable manufacturing systems. Powertrain Int 5(3):14–21

Bryan A, Ko J, SJ H, Koren Y (2007) Co-evolution of product families and assembly systems. CIRP Ann 56(1):41–44. https://doi.org/10.1016/j.cirp.2007.05.012

Wiendahl HP, ElMaraghy HA, Nyhuism P, Zah MF, Duffie N, Brieke M (2007) Changeable manufacturing—classification, design and operation. CIRP Ann 56(2):783–809. https://doi.org/10.1016/j.cirp.2007.10.003

Renna P, Ambrico M (2011) Evaluation of cellular manufacturing configurations in dynamic conditions using simulation. Int J Adv Manuf Technol 56(9-12):1235–1251. https://doi.org/10.1007/s00170-011-3255-0

Kashkoush M, ElMaraghy HA (2014) Product family formation for reconfigurable assembly systems. Procedia CIRP 17:302–307

Goyal KK, Jain P, Jain M (2013) A comprehensive approach to operation sequence similarity based part family formation in the reconfigurable manufacturing system. Int J Prod Res 51(6):1762–1776. https://doi.org/10.1080/00207543.2012.701771

Rakesh K, Jain P, Mehta N (2010) A framework for simultaneous recognition of part families and operation groups for driving a reconfigurable manufacturing system. J Adv Prod Eng Manag 5:45–58

Azab A, ElMaraghy HA (2007) Sequential process planning: a hybrid optimal macro level approach. J Manuf Syst 26(3):147–160. https://doi.org/10.1016/j.jmsy.2008.03.003

Shabaka AI, ElMaraghy HA (2008) A model for generating optimal process plan in RMS. Int J Comput Integr Manuf 21(2):180–194. https://doi.org/10.1080/09511920701607741

Chaube A, Benyoucef L, Tiwari M (2012) An adapted NSGA-2 algorithm based dynamic process plan generation for a reconfigurable manufacturing system. J Intell Manuf 23(4):1141–1155. https://doi.org/10.1007/s10845-010-0453-9

Youssef AM, ElMaraghy HA (2007) Optimal configuration selection for reconfigurable manufacturing systems. Int J Manuf Syst 19(2):67–106. https://doi.org/10.1007/s10696-007-9020-x

Aboufazili N (2012) Reconfigurable machine tool and measuring reconfigurable for design evaluation. The Royal Institute of Technology, Sweden

Moon YM, Kota S (2002) Design of reconfigurable machine tools. J Manuf Sci Eng 124(2):480–483. https://doi.org/10.1115/1.1452748

Shabaka AI, ElMaraghy HA (2007) Generation of machine configurations based on product features. Int J Comput Integr Manuf 20(4):355–369. https://doi.org/10.1080/09511920600740627

Bryan A, Ko J, SJ H, Koren Y (2007) Co-evolution of product families and assembly systems. CIRP Ann Manuf Technol 56(1):41–44

Kumar C, Deb S (2012) Generation of optimal sequence of machining operations in set up planning by genetic algorithms. J Adv Manuf Syst 11(1):67–80. https://doi.org/10.1142/S0219686712500059

Goyal KK, Jain PK, Jain M (2012) Optimal configuration selection for reconfigurable manufacturing system using NSGA II and TOPOSIS. Int J Prod Res 50(15):4175–4191. https://doi.org/10.1080/00207543.2011.599345

Bensmaine A, Dahane M, Benyoucef L (2013) A non-dominated sorting genetic algorithm based approach for optimal machines selection in reconfigurable manufacturing environment. Comput Ind Eng 66(3):519–524. https://doi.org/10.1016/j.cie.2012.09.008

Baqai A (2010) Co-conception des processus d‟usinage et des configurations cinematiques d‟un systeme de production reconfigurable. (Doctoral dissertation, Arts et Metiers Paris Tech), France, NNT: 2010-ENAM- 0010

Mohapatra P, Benyoucef L, Tiwari MK (2013) Integration of process planning and scheduling through adaptive setup planning: a multi-objective approach. Int J Prod Res 51(23–24):7190–7208. https://doi.org/10.1080/00207543.2013.853890

Mohapatra P, Nayak A, Kumar SK, Tiwari MK (2015) Multi-objective process planning and scheduling using controlled elitist non-dominated sorting genetic algorithm. Int J Prod Res 53(6):1712–1735. https://doi.org/10.1080/00207543.2014.957872

Bensmaine A, Dahane M, Benyoucef L (2014) A new heuristic for integrated process planning and scheduling in reconfigurable manufacturing system. Int J Prod Res 52(12):3583–3594. https://doi.org/10.1080/00207543.2013.878056

Azab A, Naderi B (2015) Modelling the problem of production scheduling for reconfigurable manufacturing systems. CIRP Conf Intell Comput Manuf Eng 33:76–80

Benderbal HH, Dahane M, Benyoucef L (2017) Flexibility-based multi-objective approach for machines selection in reconfigurable manufacturing system (RMS) design under unavailability constraints. Int J Prod Res 55(20):6033–6051. https://doi.org/10.1080/00207543.2017.1321802

Benderbal HH, Dahane M & Lyes Benyoucef (2017) Modularity assessment in reconfigurable manufacturing system (RMS) design: an archived multi-objective simulated annealing-based approach. Int J Adv Manuf Technol 1–21

Xie N, Li A, Xue W (2012) Cooperative optimization of reconfigurable machine tool configurations and production process plan. Chin J Mech Eng 25(5):982–989. https://doi.org/10.3901/CJME.2012.05.982

Gyulai D, Kadar B, Monosotori L (2015) Robust production planning and capacity control for flexible assembly lines. IFAC Papers Online 48(3):2312–2317. https://doi.org/10.1016/j.ifacol.2015.06.432

Zhang R, Ong SK, Nee AY (2015) A simulation-based genetic algorithm approach for remanufacturing process planning and scheduling. Appl Soft Comput 37:521–532. https://doi.org/10.1016/j.asoc.2015.08.051

Hees A, Reinhart G (2015) Approach for production planning in reconfigurable manufacturing systems. 9th CIRP conference on intelligent Computing 33: 70–75

ElMaraghy HA, Moussa M, ElMaraghy W, Abbas M (2017) Integrated product/system design and planning for new product family in a changeable learning factory. Proceedings of 7th International Conference on Learning Factories 65-72

Navaei J, ElMaraghy HA (2017) Optimal operations sequence retrieval from master operations sequence for part/product families. Int J Prod Res 1-24. https://doi.org/10.1080/00207543.2017.1391417

Hassan F, Jain PK, Kumar D (2013) Optimum configuration selection in reconfigurable manufacturing system involving multiple part families. Opsearch 51(2):297–311

Hassan SM, Baqai A (2013) An approach for the selection of process plans based on part family changes. Adv Sustain Compet Manuf Syst 65–77

Abbas M, ElMaraghy H (2017) Synthesis and optimization of manufacturing systems configuration using co-platforming. CIRP J Manuf Sci Technol (in press)

Goyal KK, Jain PK, Jain M (2013) A novel methodology to measure the responsiveness of RMTs in reconfigurable manufacturing system. J Manuf Syst 32(4):724–730. https://doi.org/10.1016/j.jmsy.2013.05.002

Venter G (2010) Review of optimization techniques. Encycl Aerospace Eng. https://doi.org/10.1002/9780470686652.eae495

Sastry K, Goldberg D, Kendall G (2014) Genetic algorithms. In:Burke E, Kendall G. (eds) Search Methodologies. Springer, Boston MA

Asghar E, Baqai AA, Zaman UKU (2015) Performance of NSGA-II and WGA in macro level process planning considering reconfigurable manufacturing system. Proceedings of 25th International Conference on Flexible Automation and Intelligent Manufacturing 2: 320-327

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Asghar, E., Zaman, U.K.u., Baqai, A.A. et al. Optimum machine capabilities for reconfigurable manufacturing systems. Int J Adv Manuf Technol 95, 4397–4417 (2018). https://doi.org/10.1007/s00170-017-1560-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1560-y